Industrial wastewater treatment device and method

A technology for industrial wastewater and treatment devices, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of insufficient industrial wastewater treatment capacity, unsuitable for industrial wastewater treatment, industrial wastewater Small processing capacity and other issues, to achieve the effect of reducing the difficulty and workload of water treatment, simple structure, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

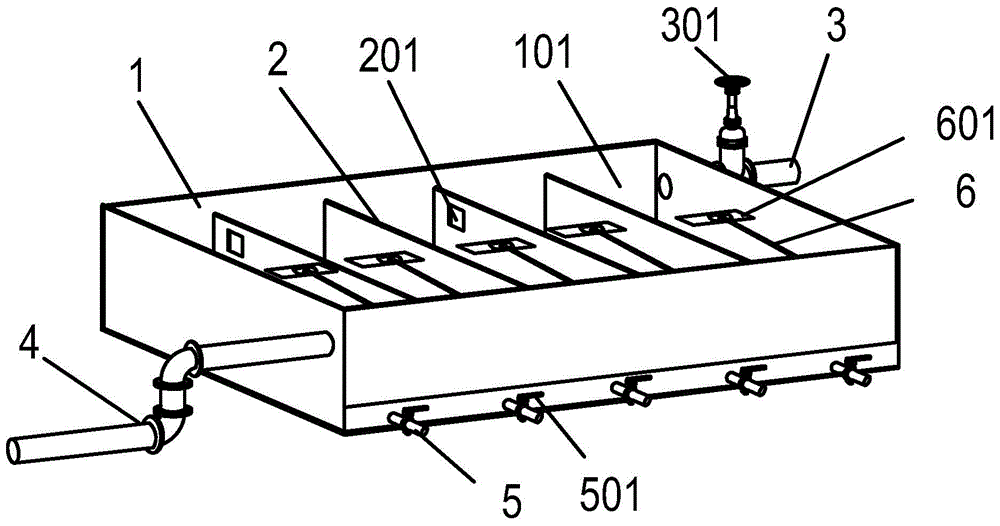

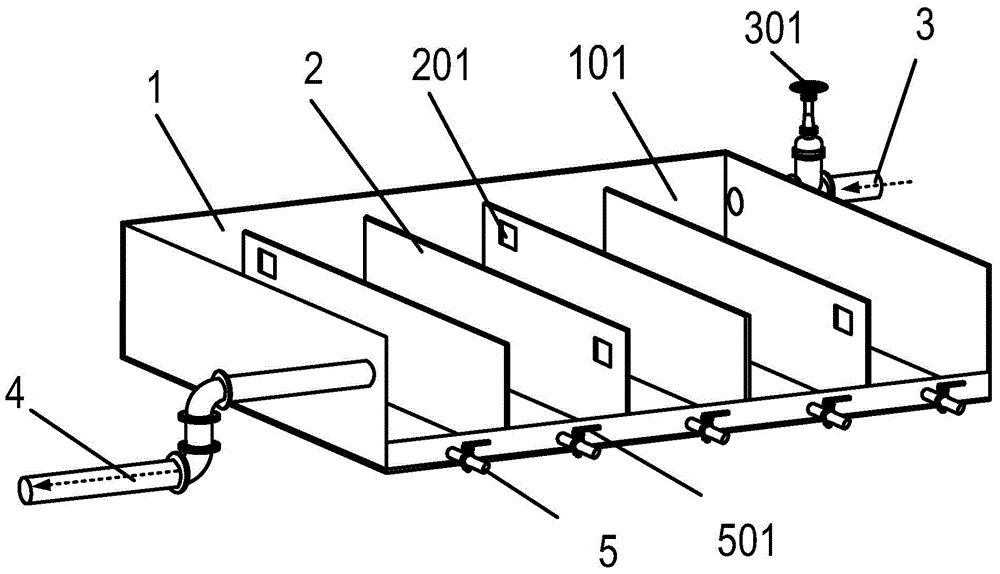

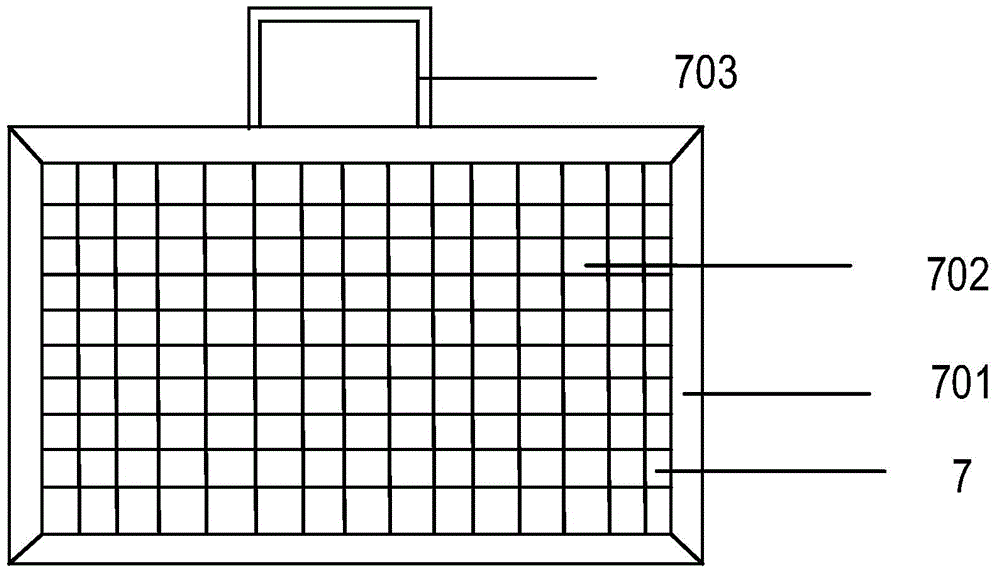

[0037] like figure 1 , 2 As shown, the industrial wastewater treatment device of the present invention includes a waste water treatment tank 1, a water inlet pipe 3 and an outlet pipe 4 communicating with the space in the waste water treatment tank 1, and also includes at least two partitions 2, the water inlet pipe 3 and the outlet pipe 4. The water pipes 4 are respectively arranged on the side walls of the waste water treatment tank 1 on opposite sides of the tank, and the partitions 2 are sequentially arranged in the space in the tank between the water inlet pipe 3 and the water outlet pipe 4, and the partitions 2 connect the waste water treatment tank 1 to the inside of the tank. The space is divided into at least three water tanks 101; an overflow port 201 is provided on the partition board 2, and the overflow ports 201 of two adjacent partition b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com