Method for preparing extra-large pore diameter hollow mesoporous organic silicon nanoparticles

A nanoparticle and silicone technology, applied in the field of nanomaterials, can solve problems such as the inability to prepare ultra-large-pore silicone nanoparticles, and achieve the effects of accelerating transmission speed, increasing loading capacity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

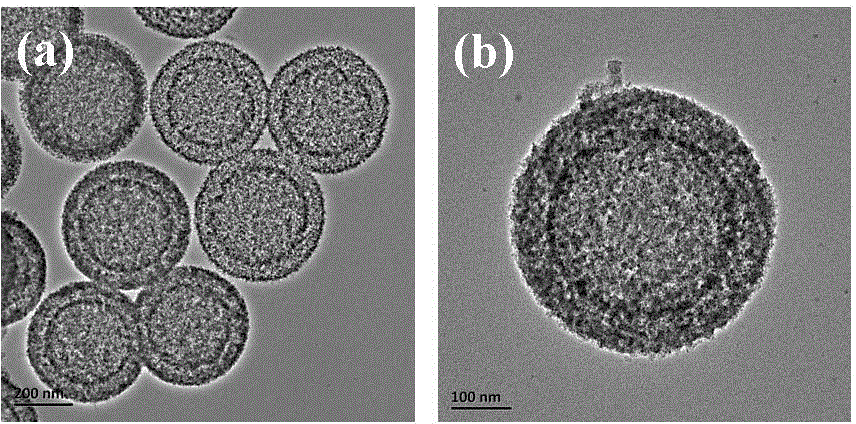

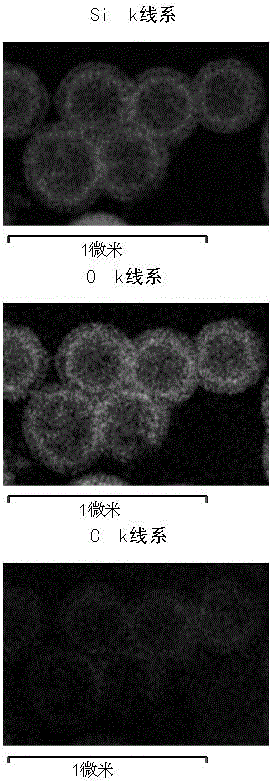

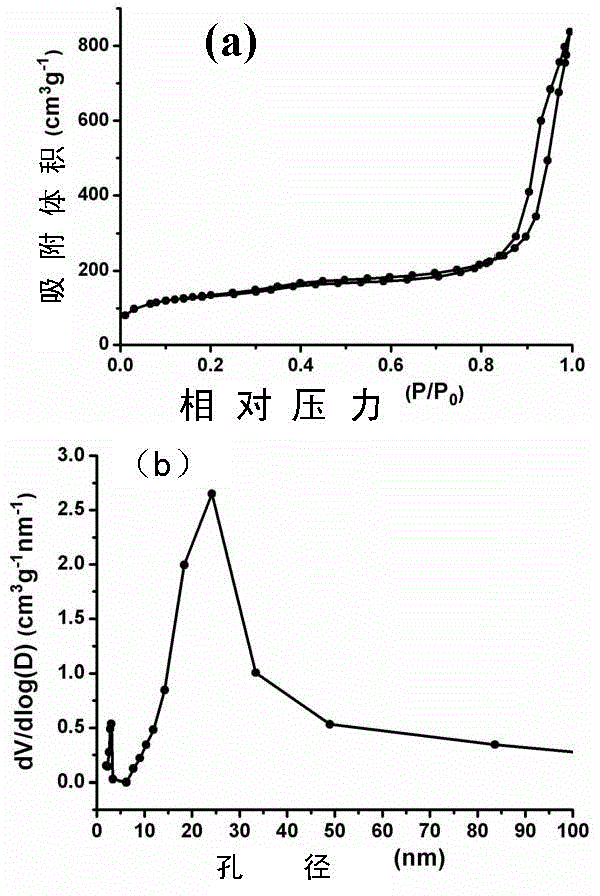

[0024] The invention relates to a method for preparing hollow mesoporous organic silicon nanoparticles with double-shell layers with super large apertures. First, the organic silicon spheres with solid core / mesoporous shell with high dispersion and uniform particle size were synthesized by sol-gel method plus surfactant-guided method; then the solid core was removed by etching under alkaline conditions; finally, under hydrothermal conditions After treatment, hollow mesoporous silicone nanoparticles with ultra-large pore size and double shell were obtained. The mesoporous organosilicon nanoparticles have a unique double-shell and hollow structure, and have a large pore size, which is very beneficial to reactions involving macromolecules, such as biomacromolecules and petroleum catalytic products. The synthesis method of the invention is simple, novel and low in cost; the synthesized nano particles have extremely wide application prospects in the fields of biomacromolecule loadi...

Embodiment 1

[0047] Mix 74mL of absolute ethanol, 10mL of deionized water and 3.14mL of ammonia water, stir at 30°C for 10min; quickly add 6mL of tetraethyl orthosilicate, and magnetically stir for 1h to obtain solid SiO 2 ball; prepare a surfactant solution, that is, dissolve 1.2g of cetyltrimethylammonium bromide in 20mL of water and 10mL of absolute ethanol; the resulting solid SiO 2 Mix the spheres (the amount of SiO2 spheres is the quality obtained in the previous step) with 100mL of deionized water, 30mL of surfactant solution and 3mL of ammonia water, and quickly add 3mL of 1,4-bis(triethoxysilyl) benzene organosilicon under stirring conditions Source, after reacting for 6 hours, the organosilicon spheres with solid core mesoporous shell structure were obtained;

[0048] Disperse the obtained organic silicon spheres with solid core mesoporous shell structure (the organic silicon spheres with solid core mesoporous shell structure is the quality obtained before) in 0.6M, 30mL Na 2 CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com