Coated insulating material for overall insulation of railway switch installation device

An installation device and integral insulation technology, which is applied in the field of wrapped insulating materials, can solve the problems of permanent deformation bolts, gaps between the cladding and steel parts, and the inability to achieve the insulation effect, and achieve the effect of improving the insulation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Component A: DMTDA, M-DEA mixture 15 parts

[0059] Component B: 100 parts of prepolymer made of MDI and PTMEG with NCO%=9%.

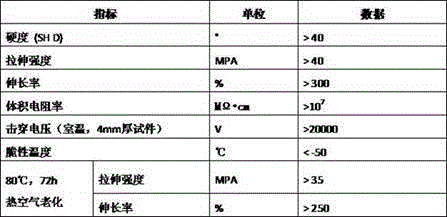

[0060] The insulating material made by mixing components A and B can achieve the following properties.

[0061]

Embodiment 2

[0063] A component: MOCA, DMTEA mixture 18 parts

[0064] Component B: 100 parts of prepolymer with NCO%=10% made of MDI, TDI, PTMEG and polyoxypropylene polyol.

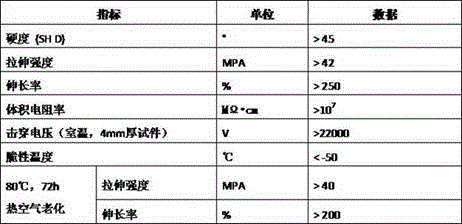

[0065] The insulating material made by mixing components A and B can achieve the following properties.

[0066]

Embodiment 3

[0068] A component: MOCA, M-MIPA mixture 16 parts

[0069] Component B: 100 parts of prepolymer made of MDI, TDI and polyoxypropylene polyol with NCO%=7%.

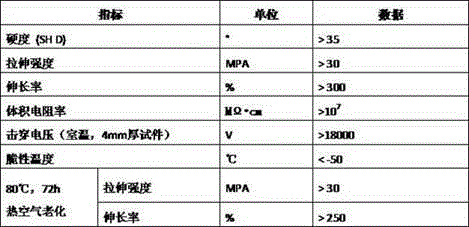

[0070] The insulating material made by mixing components A and B can achieve the following properties.

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com