Low-temperature self-repairing conductive composite material and preparation method thereof

A conductive composite material, self-healing technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., to achieve the effect of simple and easy preparation process, overcoming strict alignment, and high motion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, a low-temperature self-healing conductive material is prepared according to the following steps.

[0023] (1) Anhydrous citric acid (3.842g, 0.02mol) and N,N,N',N'-tetramethyl-1,3-propanediamine (2.604g, 0.02mol) were added to 10mL methanol solvent , stirring vigorously at room temperature for 30 minutes, so that the protonation reaction of the small molecule polycarboxylic acid and the small molecule polyamine occurs;

[0024] (2) Put the product solution obtained in step (1) in a vacuum drying oven at 60° C. for 4 days to dry to remove methanol to obtain a dried supramolecular polymer;

[0025] (3) Mix carbon nanotubes and supramolecular polymers uniformly at a mass ratio of 1:19 to obtain the target low-temperature self-healing conductive composite material.

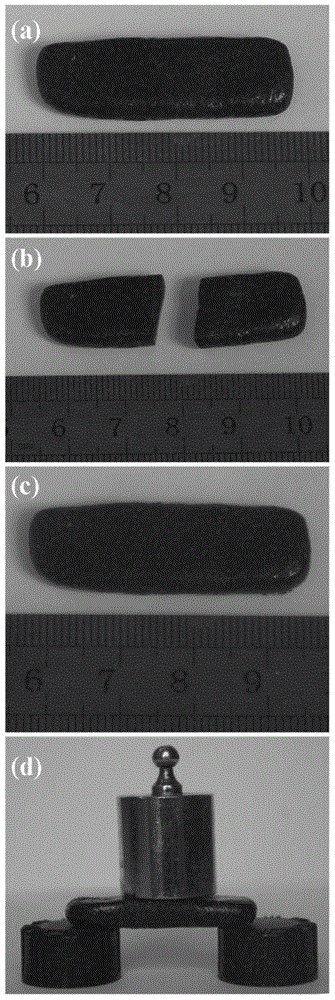

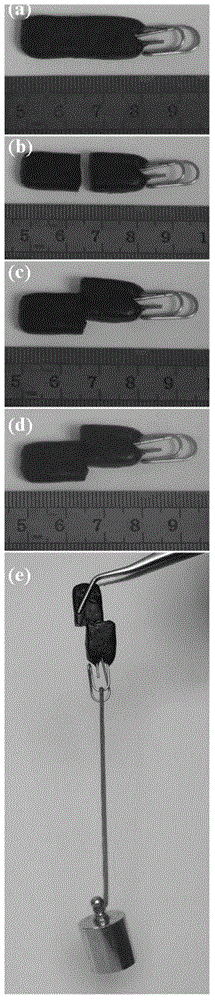

[0026] In order to characterize the self-healing performance of the self-healing conductive material obtained in this embodiment, the test is as follows:

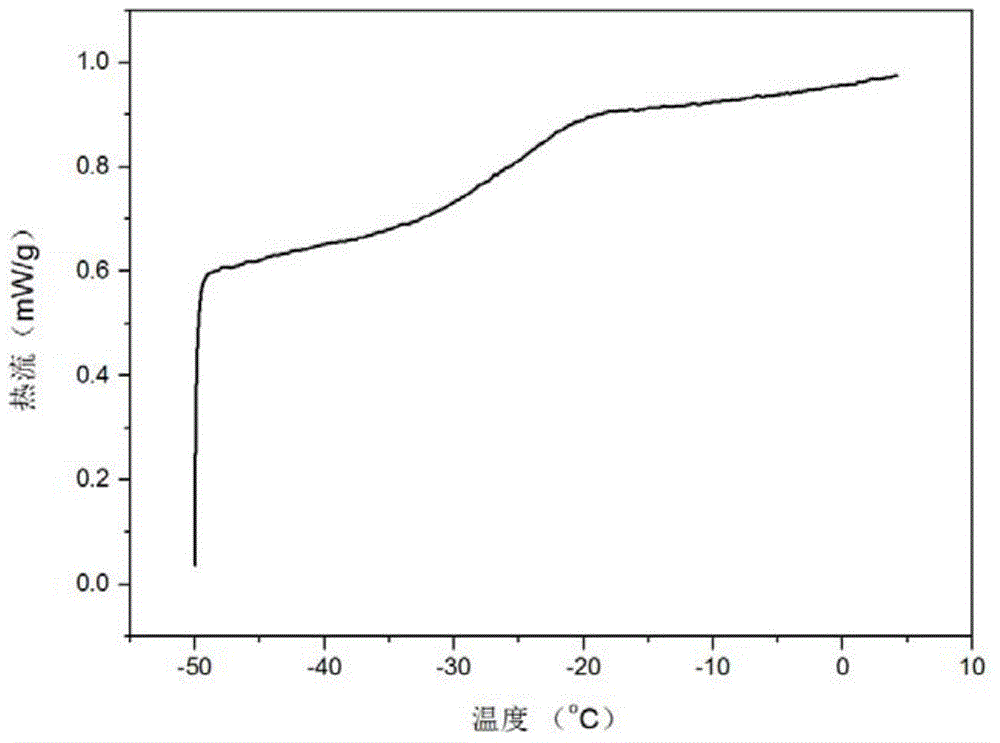

[0027] The low-temperature DSC o...

Embodiment 2

[0036] In this example, the low-temperature self-healing conductive composite material was prepared by the same method as in Example 1, the only difference being that "3.842g anhydrous citric acid" in step (1) was replaced with "7.648g anhydrous citric acid".

[0037]The same self-repair performance test as in Example 1 can be obtained: the composite material obtained in this example can support and hang 50g of weight after low-temperature repair; After 30 minutes, the resistance is 3 kohm; the original resistance at low temperature is 3.6 kohm, after cutting off and repairing at low temperature for 4 hours, the resistance value then stabilizes at 10 kohm.

Embodiment 3

[0039] This example uses the same method as Example 1 to prepare low-temperature self-healing conductive composite materials, the only difference is that: "2.604g N,N,N',N'-tetramethyl-1,3 - Propylenediamine" was replaced by "5.208 g N,N,N',N'-tetramethyl-1,3-propanediamine".

[0040] After the same self-repair performance test as in Example 1, it can be obtained that the composite material obtained in this example can support and hang 50g of weight after low-temperature repair; , and its resistance is 2.8 kohm; the original resistance at low temperature is 3.2 kohm, after cutting off and repairing at low temperature for 4 hours, the resistance value then stabilizes at 9 kohm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com