Preparation method of expanded-graphite-base hydrated salt composite solid-solid phase-change energy storage material

A technology of phase change energy storage material and expanded graphite, applied in the field of inorganic composite materials, can solve problems such as supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

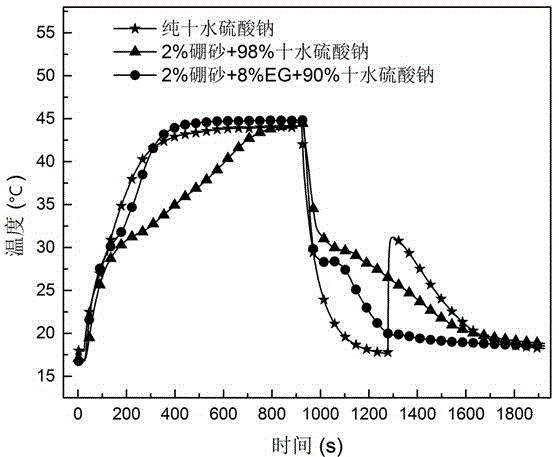

Embodiment 1

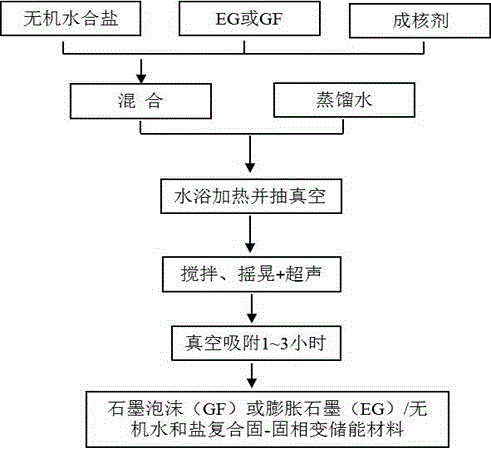

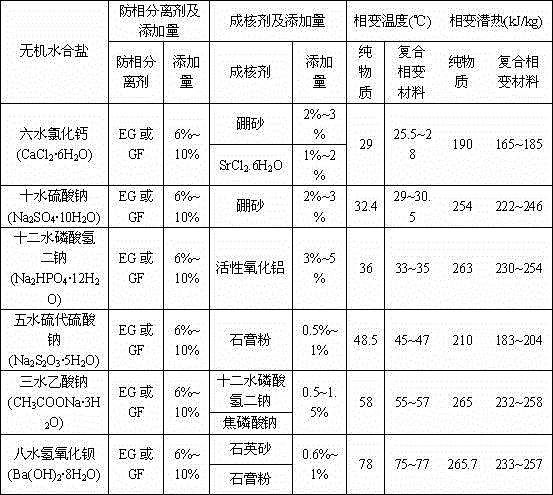

[0023] The preparation method of the expanded graphite (graphite foam) / sodium sulfate decahydrate hydrated salt composite solid-solid phase change energy storage material comprises the following steps:

[0024] (1) According to the proportioning of Table 1, with the mass ratio of sodium sulfate decahydrate: expanded graphite (graphite foam): borax=90:8:2, take by weighing 90g of sodium sulfate decahydrate, expanded graphite (graphite foam) 8g , 2 g of borax, put it into a 500 mL suction filter bottle, and add 16 g of distilled water at the same time;

[0025] (2) The mouth of the suction filter bottle is tightly plugged with a silicone plug to ensure no air leakage, the suction filter is plugged with filter cotton to prevent debris such as expanded graphite from entering the vacuum pump, and the suction filter is connected to the vacuum pump;

[0026] (3) Heat the suction filter bottle containing the phase change energy storage material in an ultrasonic constant temperature wa...

Embodiment 2

[0031] The preparation method of the expanded graphite (graphite foam) / calcium chloride hexahydrate hydrated salt composite solid-solid phase change energy storage material comprises the following steps:

[0032] (1) According to the proportioning of table 1, with calcium chloride hexahydrate: expanded graphite (graphite foam): the mass proportion of borax=89:8:3, take calcium chloride hexahydrate 89g, expanded graphite (graphite foam) Foam) 8g, borax 3g, put into 500 mL suction filter bottle, add 16g distilled water simultaneously;

[0033] (2) The mouth of the suction filter bottle is tightly plugged with a silicone plug to ensure no air leakage, the suction filter is plugged with filter cotton to prevent debris such as expanded graphite from entering the vacuum pump, and the suction filter is connected to the vacuum pump;

[0034] (3) Heat the suction filter bottle containing the phase change energy storage material in an ultrasonic constant temperature water bath at 38°C, an...

Embodiment 3

[0039] The preparation method of the expanded graphite (graphite foam) / dodecahydrate disodium hydrogen phosphate hydrated salt composite solid-solid phase change energy storage material comprises the following steps:

[0040] (1) According to the proportioning of Table 1, with disodium hydrogen phosphate dodecahydrate: expanded graphite (graphite foam): the mass proportion of activated alumina=88.5:8:3.5, take disodium hydrogen phosphate dodecahydrate 88.5g, expanded graphite (graphite foam) 8g, activated alumina 3.5g, put into 500mL suction filter bottle, add 16g distilled water at the same time;

[0041] (2) The mouth of the suction filter bottle is tightly plugged with a silicone plug to ensure no air leakage, the suction filter is plugged with filter cotton to prevent debris such as expanded graphite from entering the vacuum pump, and the suction filter is connected to the vacuum pump;

[0042] (3) Heat the suction filter bottle containing the phase change energy storage m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com