Processing method of interval transfer printing knitted bubble fabric

A transfer printing and processing method technology, applied in knitting, weft knitting, fabric surface trimming, etc., to achieve the effect of fast diffusion, bright colors, and high dye exhaustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0049] A processing method for interval transfer printing knitted bubble fabric, comprising the following steps:

[0050] Gray cloth→pre-setting→pretreatment→dyeing→dehydration→cutting→setting→heat transfer printing→inspection→packaging;

[0051]In the gray cloth, the raw materials are: 150D / 72F cationic modified DTY polyester yarn, 75D / 72F glossy fine denier polyester filament and 40D spandex yarn; the weaving method is: 8-way 150D / 72F cationic modified DTY polyester yarn +8 channels of 75D / 72F glossy fine denier polyester filament and 40D spandex weaving at intervals; weaving equipment: 28-pin weft knitting circular machine weaving, product specification: gram weight 120G / M 2 , door width 150CM.

[0052] In the presetting step, the temperature is: 165°C, the vehicle speed is: 30m / min, and the grammage is: 120G / M 2 , door width: 150CM.

[0053] In the pretreatment step, the process prescription is: degreaser: 0.8g / L; process condition: 90°C*10min.

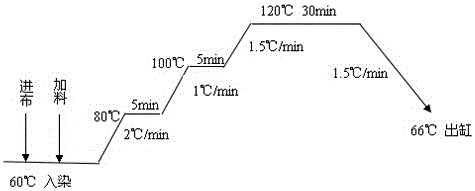

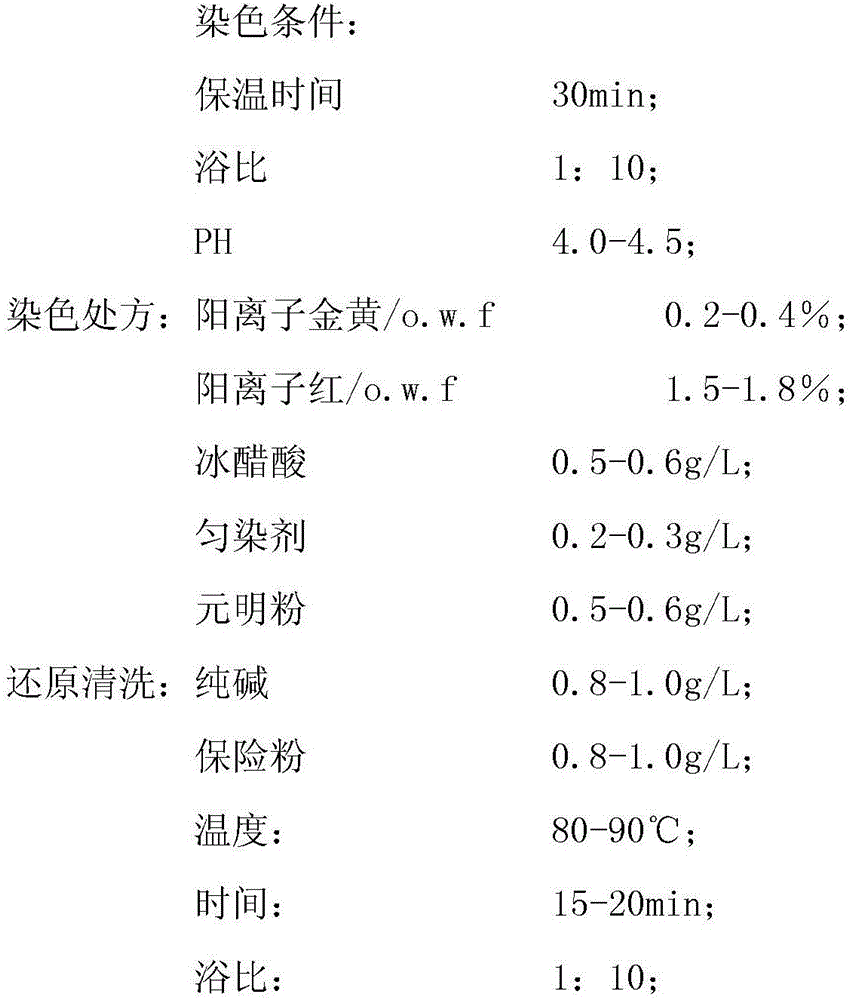

[0054] In the dyeing s...

specific Embodiment 2

[0076] A processing method for interval transfer printing knitted bubble fabric, comprising the following steps:

[0077] Gray cloth→pre-setting→pretreatment→dyeing→dehydration→cutting→setting→heat transfer printing→inspection→packaging;

[0078] In the gray cloth, the raw materials are: 150D / 72F cationic modified DTY polyester yarn, 75D / 72F glossy fine denier polyester filament and 40D spandex yarn; the weaving method is: 8-way 150D / 72F cationic modified DTY polyester yarn +8 channels of 75D / 72F bright fine denier polyester filament and 40D spandex weaving at intervals; weaving equipment: 28-pin weft knitting circular machine weaving, product specification: gram weight 130G / M 2 , door width 152CM.

[0079] In the presetting step, the temperature is: 170°C, the vehicle speed is: 50m / min, and the grammage is: 130G / M 2 , door width: 152CM.

[0080] In the pretreatment step, the process prescription is: degreaser: 1.0g / L; process condition: 90°C*20min.

[0081] In the dyeing ...

specific Embodiment 3

[0103] A processing method for interval transfer printing knitted bubble fabric, comprising the following steps:

[0104] Gray cloth→pre-setting→pretreatment→dyeing→dehydration→cutting→setting→heat transfer printing→inspection→packaging;

[0105] In the gray cloth, the raw materials are: 150D / 72F cationic modified DTY polyester yarn, 75D / 72F glossy fine denier polyester filament and 40D spandex yarn; the weaving method is: 8-way 150D / 72F cationic modified DTY polyester yarn +8 channels of 75D / 72F glossy fine denier polyester filament and 40D spandex weaving at intervals; weaving equipment: 28-needle weft knitting circular machine weaving, product specification: gram weight 124G / M 2 , door width 151CM.

[0106] In the presetting step, the temperature is: 162°C, the vehicle speed is: 40m / min, and the grammage is: 126G / M 2 , door width: 151CM.

[0107] In the pretreatment step, the process prescription is: degreaser: 0.9g / L; process condition: 90°C*14min.

[0108] In the dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com