Displacement amplifying type 2D electro-hydraulic proportional directional valve

An electro-hydraulic proportional and reversing valve technology, which is applied to valve details, multi-way valves, valve devices, etc., can solve the problems of pressure loss pilot control level leakage flow, stuck pilot control oil circuit, etc., to improve accuracy and reduce weight and volume, the effect of simplifying the structure of the valve body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

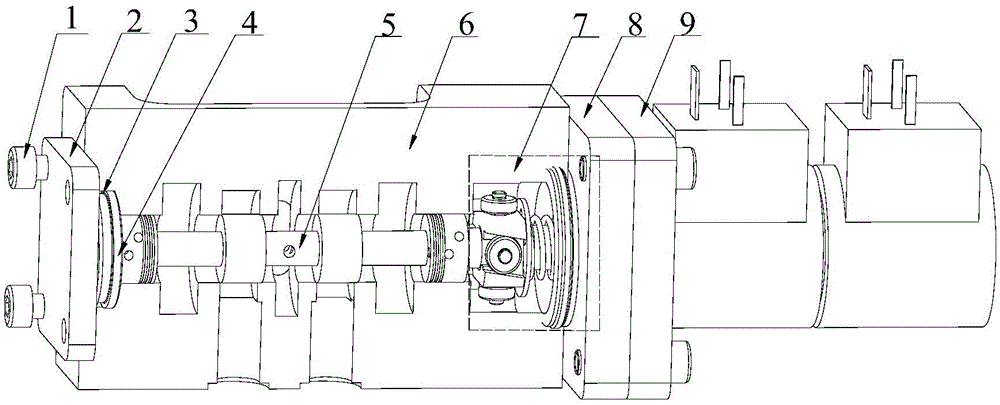

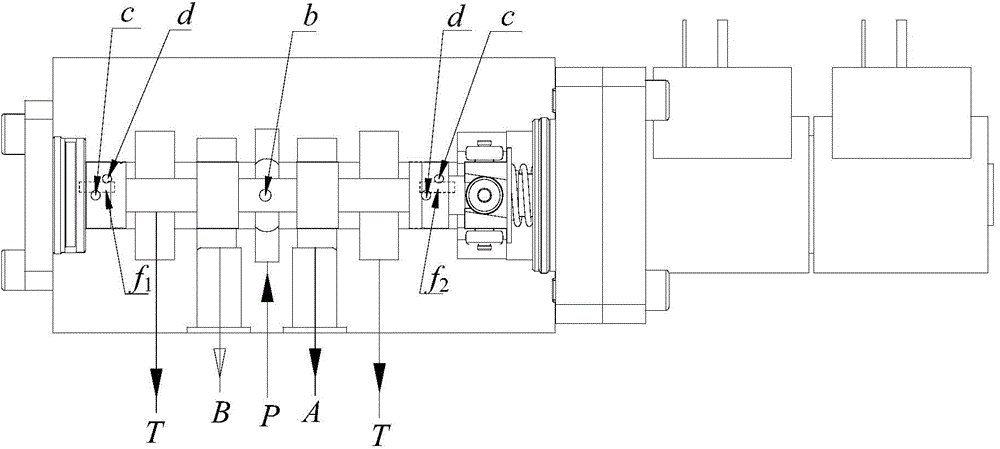

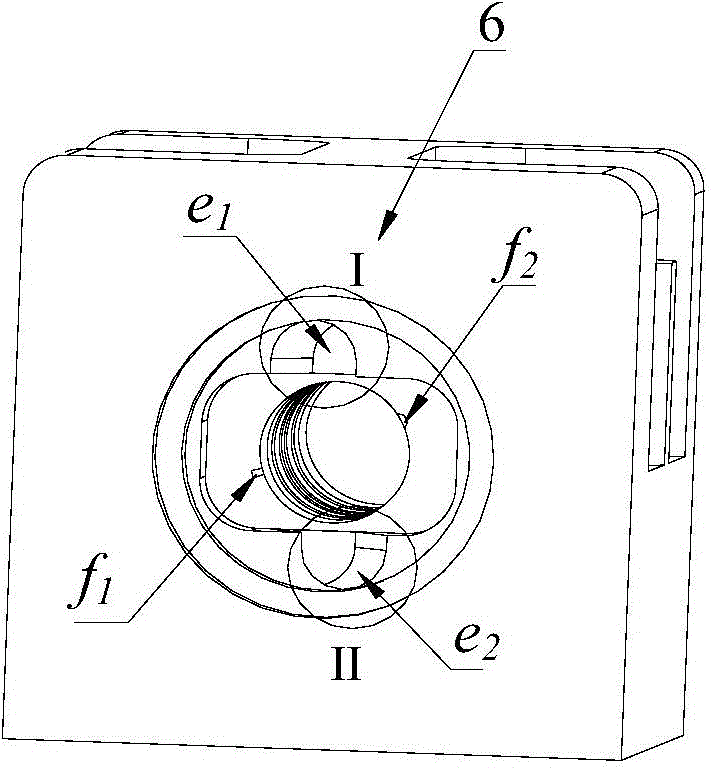

[0028] refer to figure 1 ~Fig. 6, a 2D electro-hydraulic proportional reversing valve with amplified displacement includes screw 1, left cover plate 2, left plug ring 3, O-ring 4, valve core 5, valve body 6, compression torsion assembly 7, end Cover 8, two-way proportional electromagnet 9; spool 5 includes accessory central axis 12, first roller 71 and second roller 72, elastic circlips 61 and 62, inner gaskets 51 and 52, inner spring 11 and elastic retainer Ring 65, press torsion assembly 7 includes wedge 10, third roller 73 and fourth roller 74, circlips 63 and 64, pin 13, large washer 14, outer spring 15, small washer 16 and circlip 17 . The displacement can be amplified 2D electro-hydraulic proportional reversing valve is composed of three parts: 2D valve, bidirectional pressure-torsion coupling and linear electro-mechanical converter.

[0029] The 2D valve part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com