A dynamic expansion oil pipe joint for low oil pressure

A technology for oil pipe joints and low oil pressure, which is applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, pipe components, etc., and can solve problems such as relatively high requirements, complex structures, and limited pressure bearing capacity of sealing mechanisms , to achieve the effect of improving pressure sensitivity, improving durability, convenient connection and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

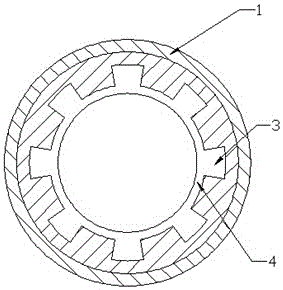

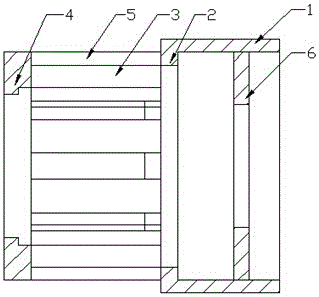

[0042] Such as Figure 1~6 As shown, this product is a self-expanding oil pipe joint, the body is a cylindrical joint body, and at one end of the joint body is a dynamic expansion oil pipe joint for low oil pressure, including a connecting part, a driving part, and a sealing part;

[0043] The connecting part includes a joint body, an equipment connector 1 is arranged at one end of the joint body, and an oil pipe connector is arranged at the other end of the joint body, and the oil pipe connector includes a fixed surface for contacting the inner wall of the oil pipe;

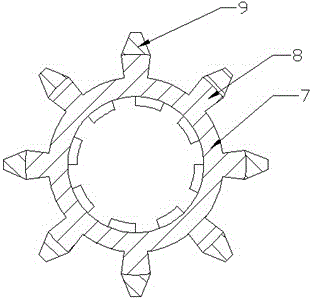

[0044]The driving part includes a driving block 7 and a push ring 10 arranged on the inner wall of the oil pipe connection head. The driving block 7 is hollow cylindrical, and a plurality of protruding keys 8 are arranged in an annular array on the outer wall of the driving block 7. The protruding The axis of the key 8 is parallel to the axis of the drive block 7, and a push key 9 is also arranged on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com