Device and method for testing stress of infrared optical material

A technology of infrared optical materials and stress testing, which is applied in the direction of measuring the change force of the optical properties of the material when it is stressed, can solve the problems of not meeting the stress test, affecting the quality of thermal imaging, glass bursting, etc., and achieve test efficiency High performance, reliable performance, and the effect of avoiding bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

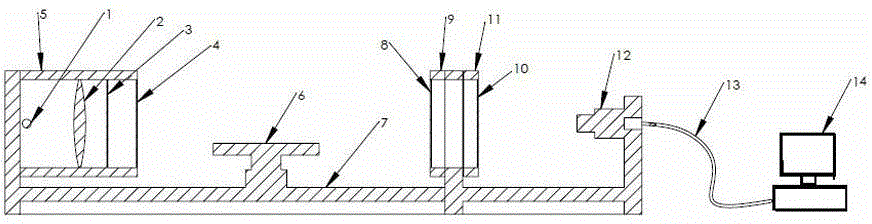

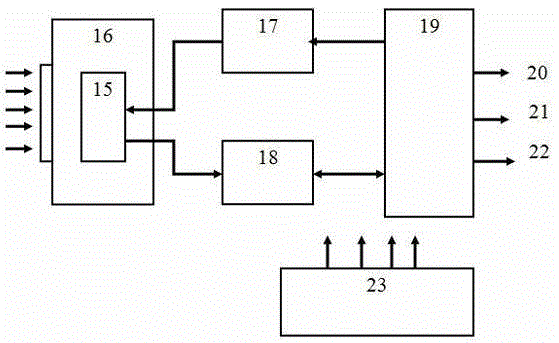

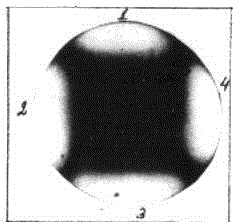

[0025] For being able to further understand technical content, characteristic and effect of the present invention, enumerate following example now, and in conjunction with Attached picture The details are as follows.

[0026] The present invention provides an infrared optical material stress testing device, which is composed of five parts: an infrared light source 1, an infrared optical system, a signal receiving system 12, a computer acquisition, processing and display system, and a testing platform 7.

[0027] Considering that the tested sample is an infrared optical material with a transmission wavelength range of 0.78-25 μm, the infrared light source 1 is designed to use a point light source, a line light source or a plane light source with an emission spectrum of near and mid-infrared. Generally, single-wavelength infrared laser diode LFO-450 and infrared helium-neon laser light source are selected, and their emission spectrum is λ=1300nm or λ=3390nm; the output power of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com