Biological soft tissue mechanical property test clamping device and method based on vacuum adsorption

A technology of biological soft tissue and test clips, which is used in measuring devices, using stable tension/pressure to test material strength, scientific instruments, etc. and other problems, to achieve the effect of easy production and promotion, reducing stress concentration problems and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Biological Soft Tissue Static Tensile Test:

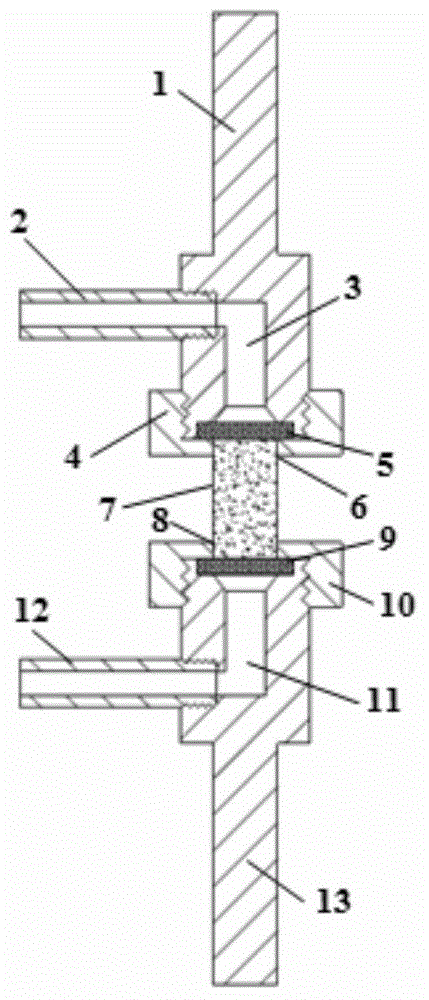

[0036] Step 1, chuck installation: use the upper chuck cap 4 to fix the upper chuck porous material sheet 5 (aperture: 0.01-0.8 mm, porosity: 10-60%) to the upper chuck 1 . Turn on the reciprocating motion testing machine and use the displacement control mode. Connect the upper chuck 1 to the upper fixed end of the reciprocating motion testing machine. Use the lower chuck cap 10 to fix the lower chuck porous material sheet 9 on the lower chuck 13, connect the lower chuck 13 to the lower fixed end of the reciprocating motion testing machine, and make the upper chuck cap central hole 6 and the lower chuck The center hole 8 of the cap is aligned.

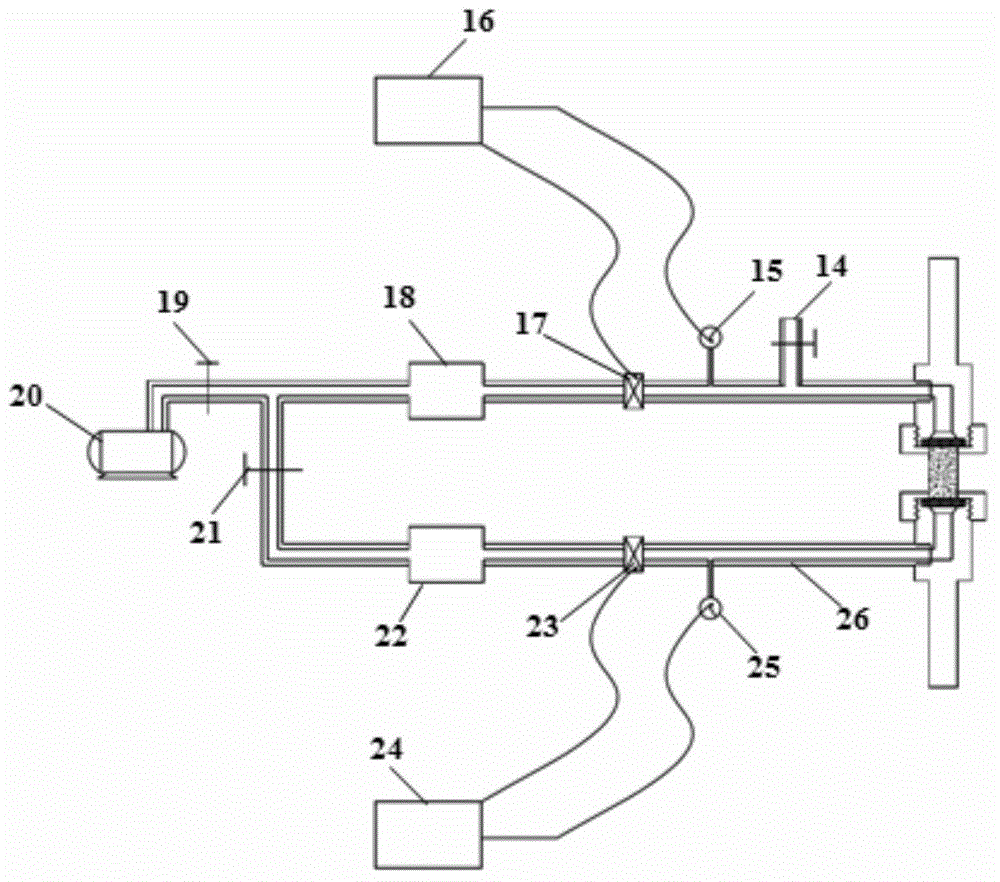

[0037]Step 2, soft tissue sample installation: 1) For the upper chuck part, connect the upper chuck connecting pipe 2 with the rubber hose 26, close the air shut-off valve 21 and the air release valve 14 in the inner chamber of the lower chuck, open the main shut-off valve 19, and ...

Embodiment 2

[0042] Dynamic tensile test of biological soft tissue:

[0043] Steps one, two, four, and five are the same as the static tensile test.

[0044] Step 3, start the reciprocating motion testing machine, set the sinusoidal displacement curve (the displacement amplitude is set as the value when the sample produces 20-40% deformation, and the frequency is 0.1-10 Hz), so that the lower chuck 13 reciprocates according to the set sinusoidal curve , record the force response curve of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com