Electrostatic drive-based surface material contact characteristic test structure and test method thereof

A surface material, electrostatic drive technology, applied in the process of producing decorative surface effects, analysis materials, microstructure technology and other directions, can solve the problems of poor test adaptability of different materials, high measurement cost, expensive equipment, etc. Accuracy test, compact size, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing of description, the present invention will be further described.

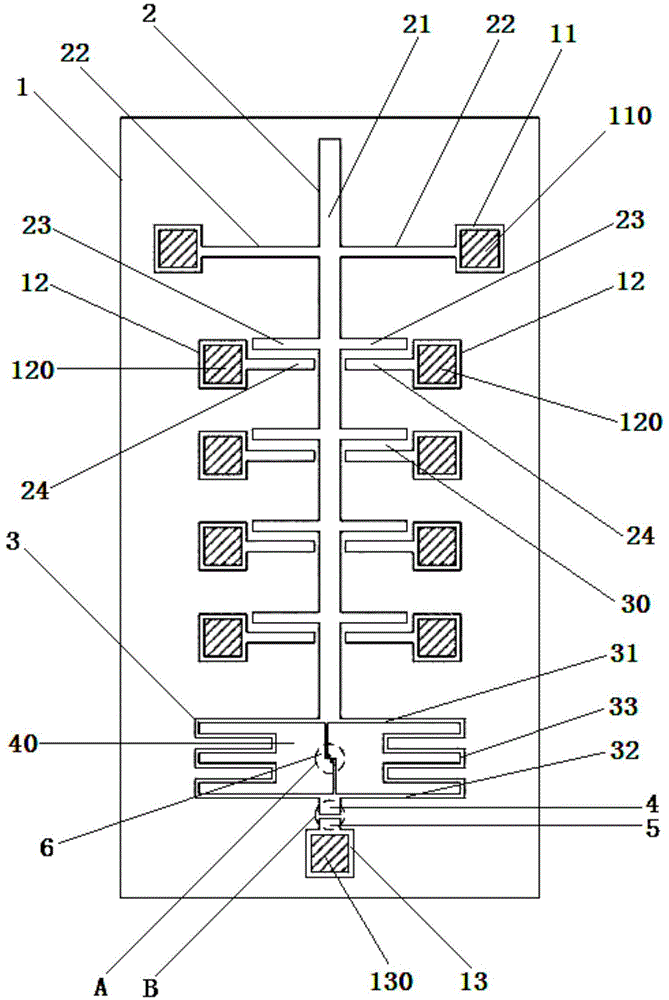

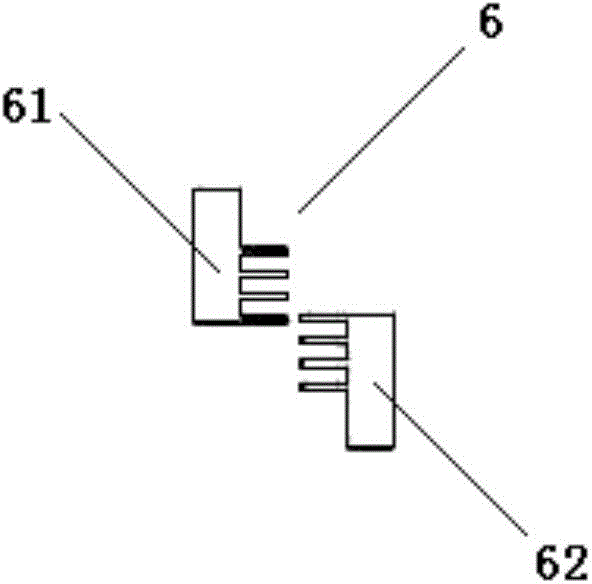

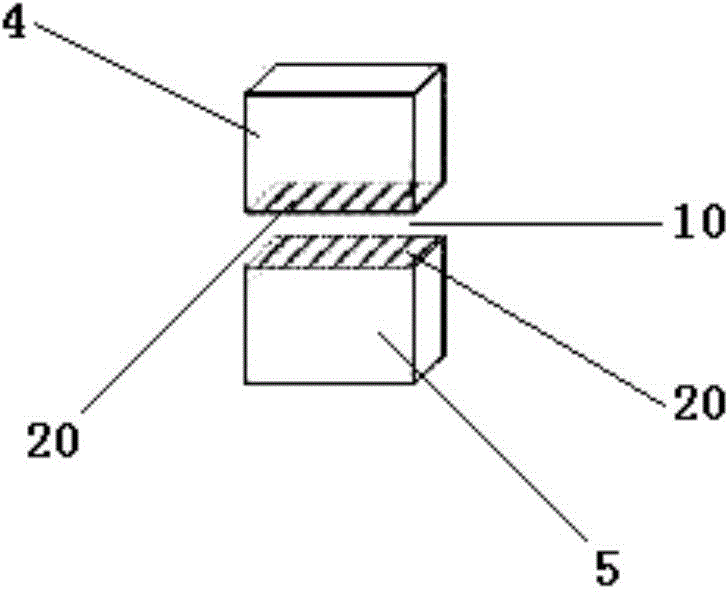

[0038] Such as figure 1 , figure 2 and image 3 As shown, a surface material contact characteristic test structure based on electrostatic drive includes an insulating substrate 1, an electrostatic actuator 2, a king-shaped spring 3, a movable Contact electrode 4 and fixed contact electrode 5; also comprise the scale structure 6 that is arranged in the king-shaped spring 3 and be used for reading test scale; The test distance 10 of initial state is separated between described movable contact electrode 4 and fixed contact electrode 5 .

[0039] The electrostatic actuator 2, the king-shaped spring 3 and the movable contact electrode 4 are sequentially connected into one body, and are maintained in a suspended state by support; the fixed contact electrode 5 is also maintained in a suspended state by support; the movable contact electrode 4 and The facing si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com