Optical element axial jogging adjustment device of bridge type flexible hinge structure

A flexible hinge and optical element technology, which is applied to optical elements, photolithography process exposure devices, optics, etc., can solve the problems of difficult structural design and manufacture, many drivers are used, and the structure space is large, so as to achieve easy adjustment of structural design and manufacture, improve Mechanical precision, the effect of simplifying the assembly and adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

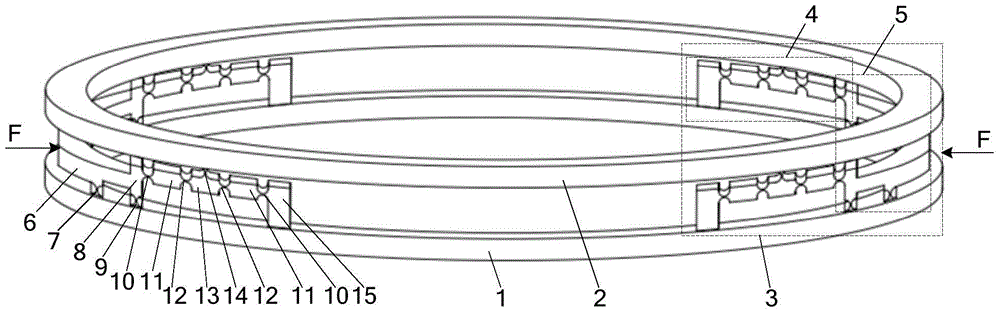

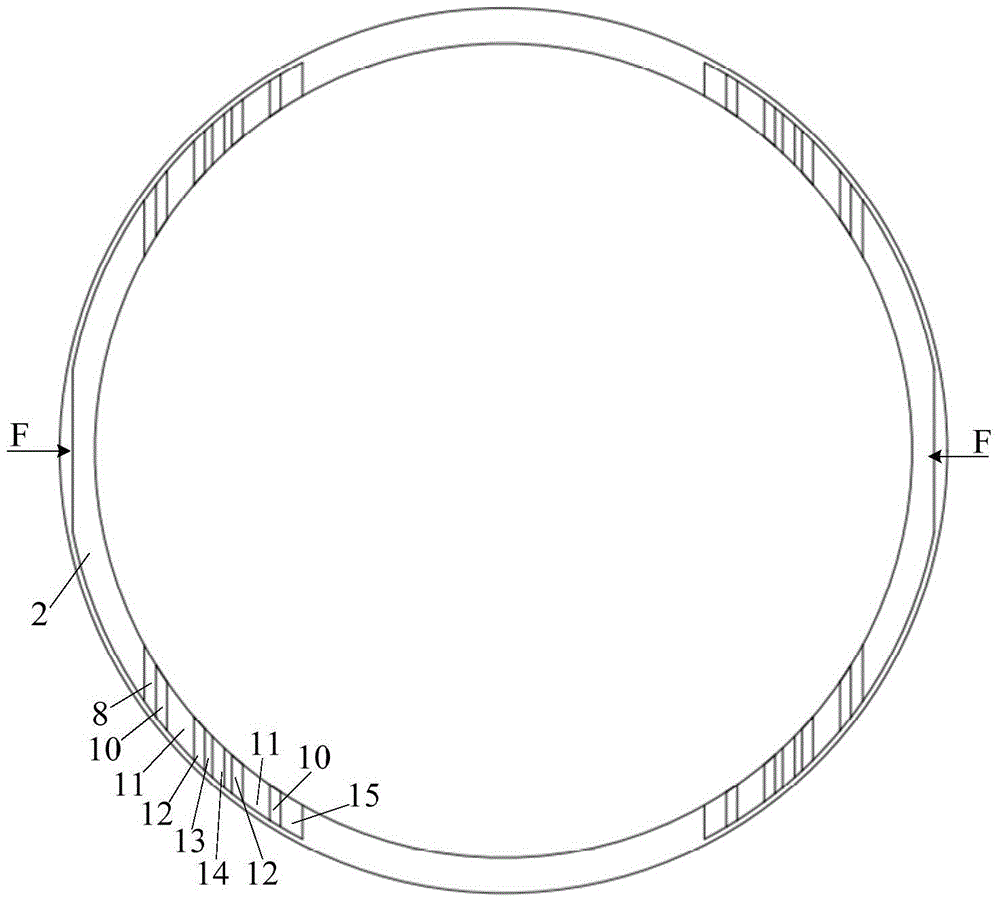

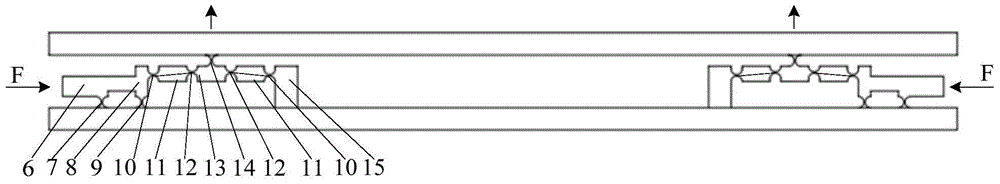

[0029] See attached figure 1 And attached figure 2 , a bridge-type flexible hinge structure optical element axial micro-adjustment device of the present invention includes a mirror base connector 1, a mirror frame connector 2 and two groups of micro-adjustment mechanisms 3;

[0030] The two groups of micro-adjustment mechanisms 3 are arranged between the mirror base connector 1 and the mirror frame connector 2, and are symmetrical about the Y axis. Each group of micro-motion adjustment mechanisms 3 includes two groups of bridge-type flexible hinges 4 and a set of Input parallel hinges 5; two groups of bridge-type flexible hinges 4 in each group of micro-adjustment mechanisms 3 are connected through input parallel hinges 5, and are symmetrical about the X axis;

[0031] The input parallel hinge 5 transmits the radial force F to the bridge-type flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com