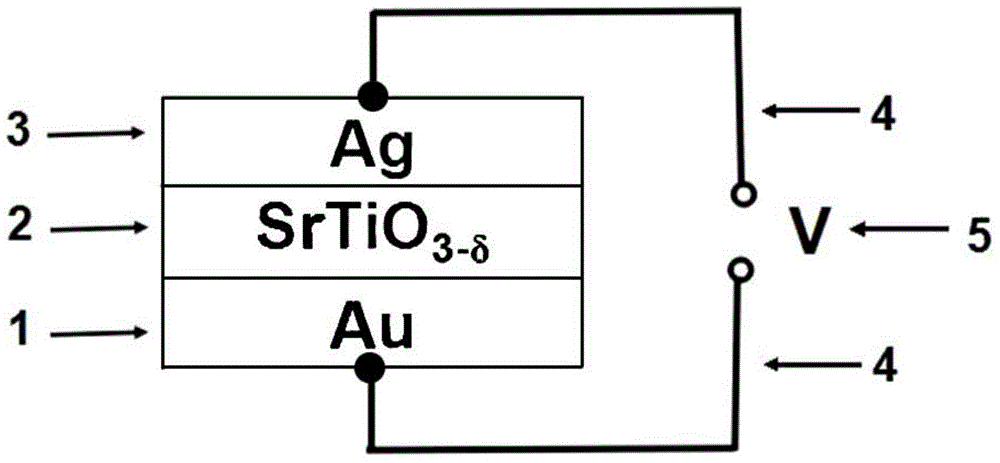

Manufacturing method of SrTiO3 single-crystal resistance switch device

A resistive switching device, single crystal technology, applied in the direction of electrical components, etc., can solve the problems of increasing the difficulty of sample preparation, achieve the effect of low equipment requirements, good performance, and avoid complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

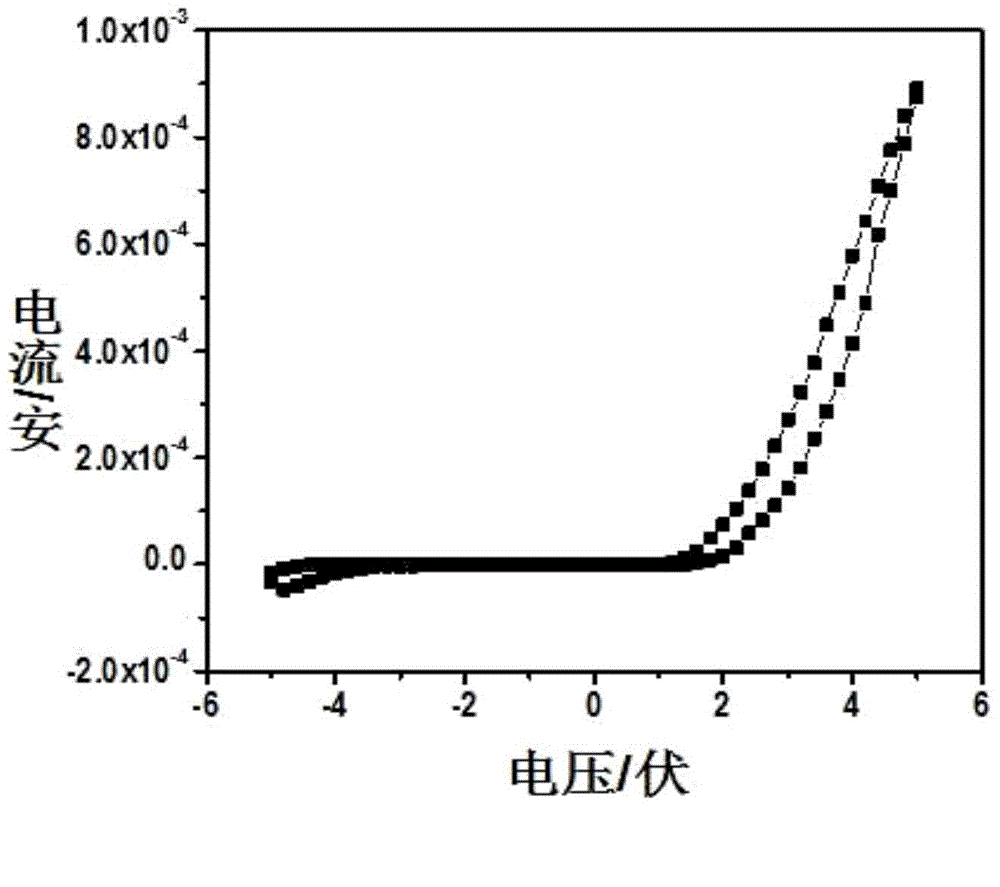

Examples

specific Embodiment

[0026] A high temperature annealed SrTiO 3 The specific steps of the preparation method of the single crystal resistance switching device are as follows:

[0027] 1) Use purchased intact undoped SrTiO 3 Single wafer 2, after cleaning, put it into a quartz glass tube with a diameter of 15mm and a length of 15-25cm, and then use a vacuum device to replace the air in the quartz glass tube with argon three times to ensure that the air in the quartz glass tube is exhausted go. After charging about 10 -4 Argon gas of Pa, this is mainly to ensure that the pressure difference inside and outside the quartz glass tube is roughly equal during heating, and will not explode due to too large a pressure difference. Finally, the oxyacetylene flame is used to fuse the quartz glass tube to play the role of sealing;

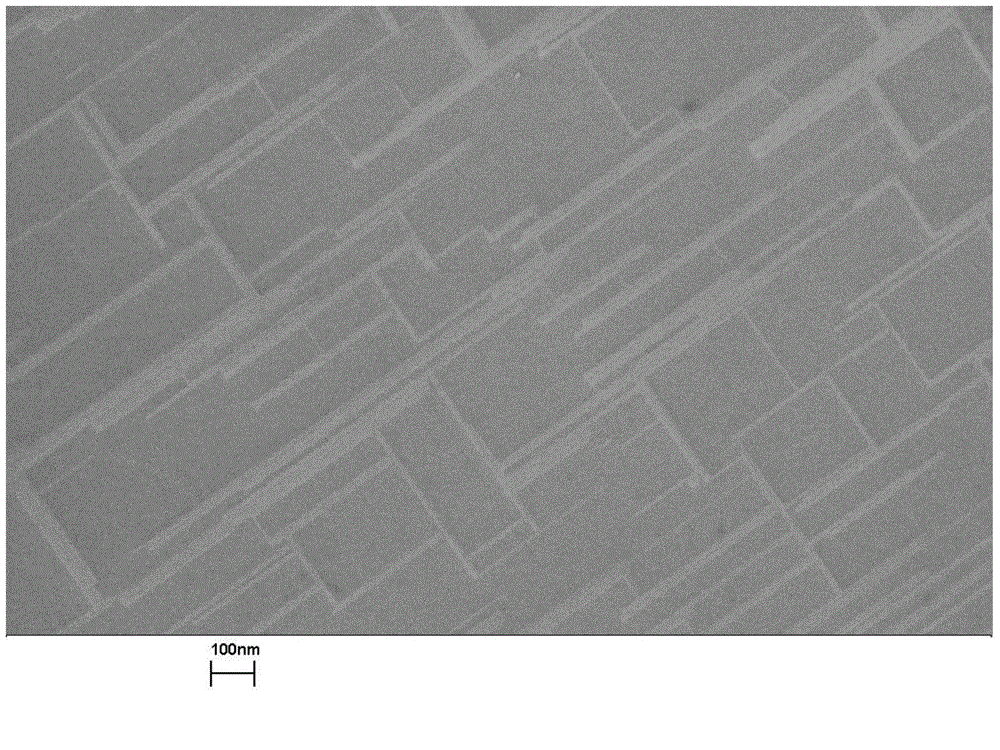

[0028] 2) the encapsulated SrTiO obtained in step 1) 3 The single wafer 2 quartz glass tubes are heated in a constant temperature well furnace, the temperature in the well fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com