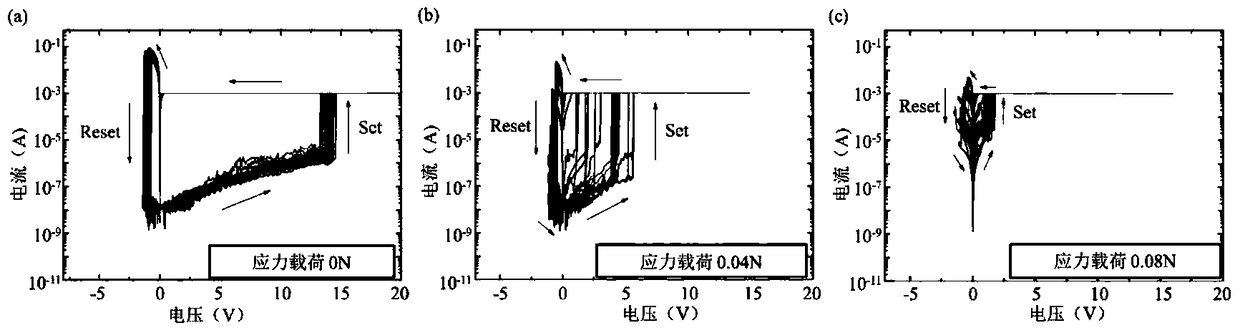

A kind of plt film whose resistive switch performance can be regulated by mechanical load and its preparation method

A thin film and magnetic stirrer technology, applied in the direction of electrical components, etc., can solve the problem of unstable resistance switching characteristics, etc., and achieve good resistance switching performance, stable resistance switching process, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

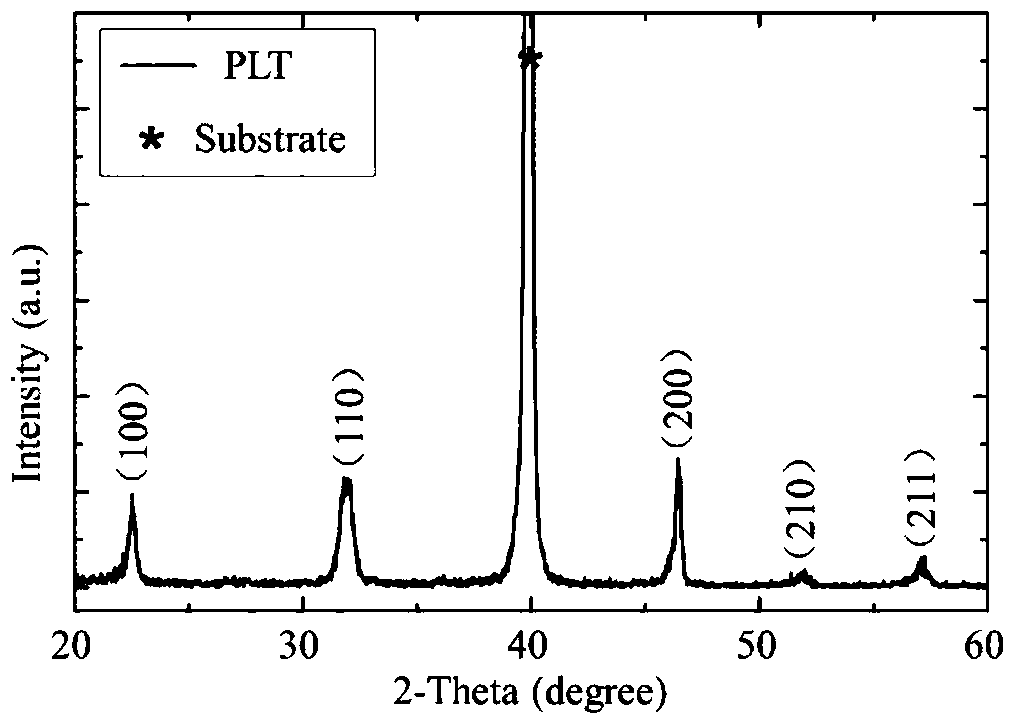

Image

Examples

Embodiment 1

[0026] 1) Place the substrate in a mixture of acetone, isopropanol, and deionized water (1:1:1 volume ratio of acetone: isopropanol: deionized water), ultrasonically clean for 5 minutes; Ultrasonic cleaning with deionized water for 1 minute; dry the substrate with high-purity nitrogen.

[0027] 2) Dissolve 5 mmol of lead acetate trihydrate in 10 ml of glacial acetic acid, and stir at a constant temperature of 110°C on a magnetic stirrer until the raw materials are dehydrated. After cooling, slowly add 5 mmol tetrabutyl titanate, and stir until the first solution is uniform.

[0028] 3) Dissolve 0.1mmol of lanthanum nitrate in 10ml of ethylene glycol methyl ether, and stir at a constant temperature of 60°C on a magnetic stirrer until the second solution is uniform and cooled.

[0029] 4) Slowly add the first solution into the second solution, fully stir and age for 24 hours to obtain the precursor.

[0030] 5) Inhale the precursor with a 2ml syringe, and install a 0.22μm filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com