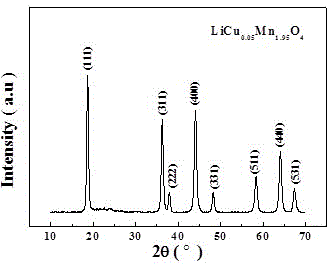

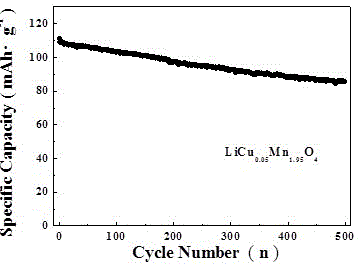

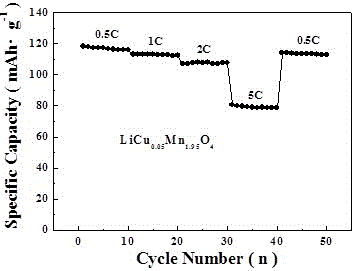

One-step method for preparing high-magnification copper-doped lithium manganese dioxide lithium ion battery positive electrode material

A lithium ion battery, lithium heteromanganate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex process steps, product specific capacity, rate performance and cycle performance can not meet the application of power battery and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1.1411 g of lithium nitrate, 7.9106 g of manganese acetate and 0.1652 g of copper acetate in a 300 mL crucible, add 10 mL of 9 mol / L dilute nitric acid and stir to dissolve to obtain a uniform mixed solution. Put it into a muffle furnace with a preheated constant temperature of 600 °C, and close the door of the muffle furnace. After heating for 3 hours, take out the crucible from the muffle furnace and place it in the air to cool to room temperature to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com