An anti-impact silicon based MEMS microphone, a system and a package with the same

A microphone and impact-resistant technology, which is applied in the field of microphones, can solve the problem that the sound pressure impact of the microphone is easily damaged, and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

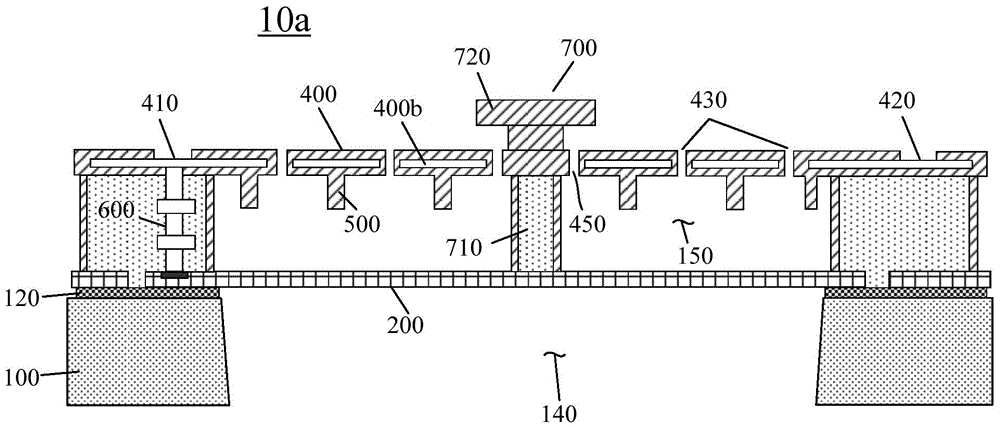

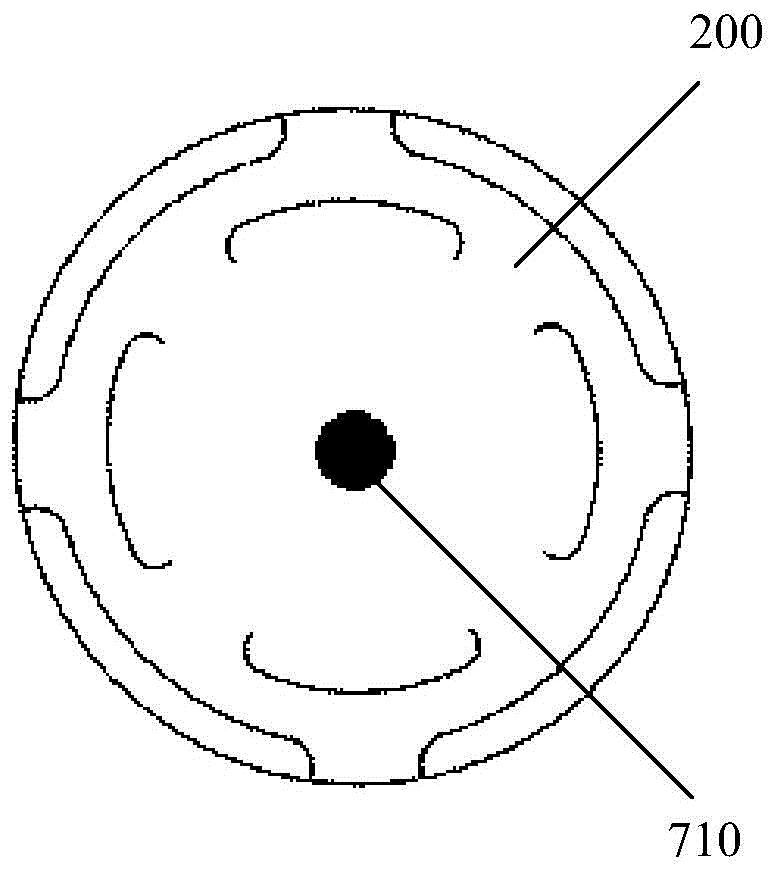

[0043] figure 2 is a cross-sectional view showing the structure of the shock-resistant silicon-based MEMS microphone according to the first embodiment of the present invention. image 3 is a plan view showing figure 2 An example pattern of the microphone diaphragm in when viewed from its top side. MEMS microphones can receive acoustic signals and convert the received acoustic signals into electrical signals for subsequent processing and output. Such as figure 2 As shown, the shock-resistant silicon-based MEMS microphone 10 a according to the first embodiment of the present invention includes a silicon substrate 100 with a back hole 140 , a conductive and compliant diaphragm 200 , a perforated back plate 400 , and an air gap 150 . The diaphragm 200 is formed using a part of the silicon device layer such as the top silicon film on a silicon-on-insulator (SOI) wafer or using a polysilicon thin film formed by a deposition process, and the diaphragm 200 is stacked on the sili...

no. 2 example

[0051] Figure 6 is a cross-sectional view showing the structure of the shock-resistant silicon-based MEMS microphone according to the second embodiment of the present invention. Figure 7 is a plan view showing Figure 6 An example pattern of the microphone diaphragm in when viewed from its top side.

[0052] Compared Figure 6 and figure 2 and contrast Figure 7 and image 3 The difference between the shock-resistant silicon-based MEMS microphone 10b described in the second embodiment and the shock-resistant silicon-based MEMS microphone in the first embodiment is that, in the second embodiment, the uniform and / Or symmetrically form a plurality of first through holes 450, and uniformly and / or symmetrically form a limiter mechanism including a plurality of limiters 700 near the edge of the diaphragm 200, and the plurality of limiters 700 are connected to a plurality of Corresponding to the first through hole 450, each T-shaped limiter 700 has a lower portion 710 an...

no. 3 example

[0054] Figure 8 is a cross-sectional view showing the structure of the shock-resistant silicon-based MEMS microphone according to the third embodiment of the present invention.

[0055] Compared Figure 8 and Figure 6 The difference between the shock-resistant silicon-based MEMS microphone 10c in the third embodiment and the shock-resistant silicon-based MEMS microphone in the second embodiment is that in the third embodiment, the shock-resistant silicon-based MEMS microphone 10c includes interconnection columns 600, the interconnection column 600 is set between the center of the diaphragm 200 and the center of the back plate 400, and is used to suspend the diaphragm 200 mechanically and lead the diaphragm 200 outward electrically, the diaphragm 200 The perimeter is free to vibrate. An example of the above-mentioned structure of the microphone 10c and its manufacturing method is described in detail in International Application No. PCT / CN2010 / 075514, the relevant content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com