Forming equipment producing anti-breakage paper diapers

A molding equipment and technology for diapers, applied in the fields of medical science, clothing, underwear, etc., can solve the problems of inability to produce anti-break diapers, diapers that cannot store liquid, and no anti-break diapers, etc., to improve infiltration and diversion speed and diffusion. The effect of area, uniformity of absorber, improved production efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

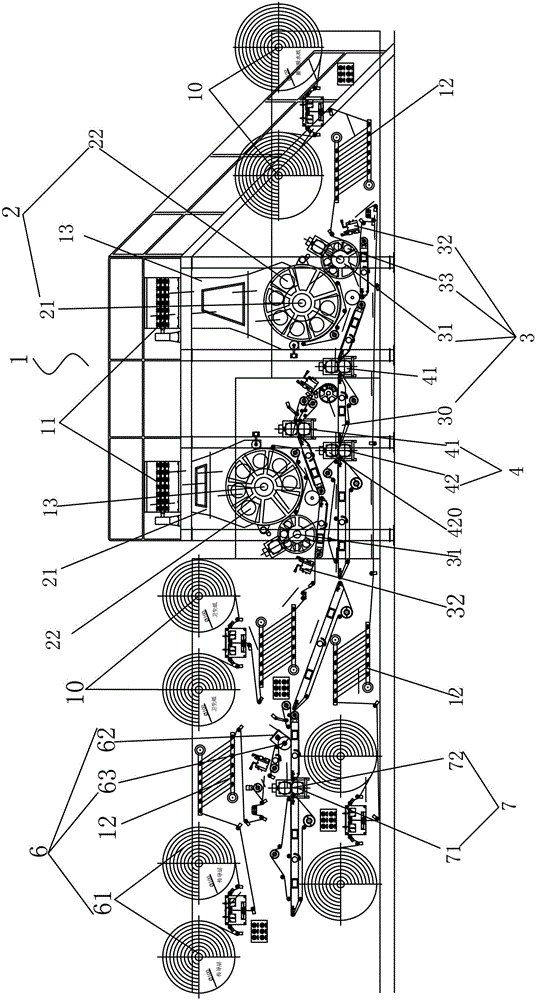

[0038] Specific implementation methods, such as Figure 1 to Figure 5 As shown, a molding device for producing breakage-resistant diapers according to the present invention includes the following mechanisms: a feeding assembly 1, and at least two sets of suction mechanisms 2, a transmission mechanism 3, and a heat-pressing and heat-synthesizing mechanism 4, Conductive layer chopping mechanism 6, cotton core chopping mechanism 7;

[0039] Feed assembly 1, which includes a roller 10 with puffed paper and non-woven fabric, and a pulverizer 11; the pulverizer 11 breaks wood pulp and mixes it with fluff pulp to form fiber batting (absorbent body), which is sent to the absorbent The wind mechanism 2 is directly attached to the net wheel 21 surface on the suction mechanism by the feed channel 13; the feed channel 13 is arranged on the net wheel top and at least 1 / 3rd of the net wheel 21 periphery is placed in the feed channel 13 , in order to facilitate the attachment of fiber cotto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com