System and method for measuring vibration situation of strip steel in gas cooling section

A gas cooling, strip steel technology, applied in the direction of length measuring device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of deteriorating cooling effect, strip steel and nozzle collision, etc., achieve wide range of amplitude and frequency, and easy maintenance , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

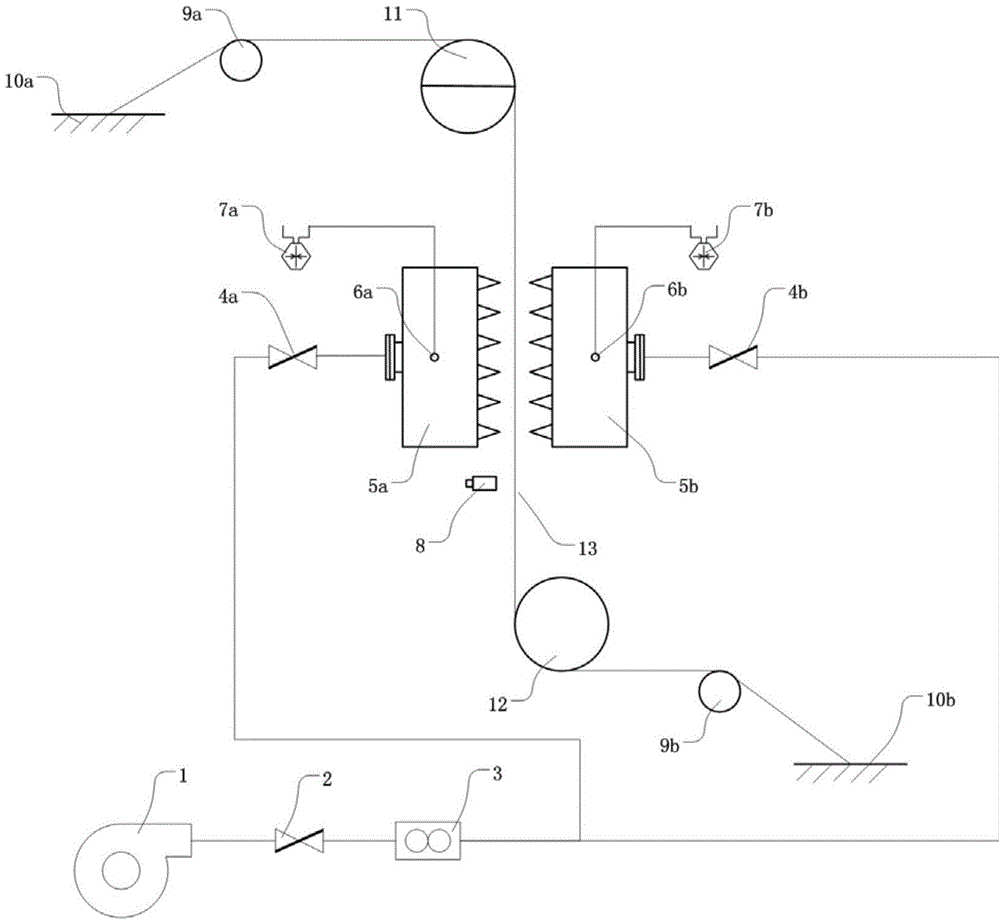

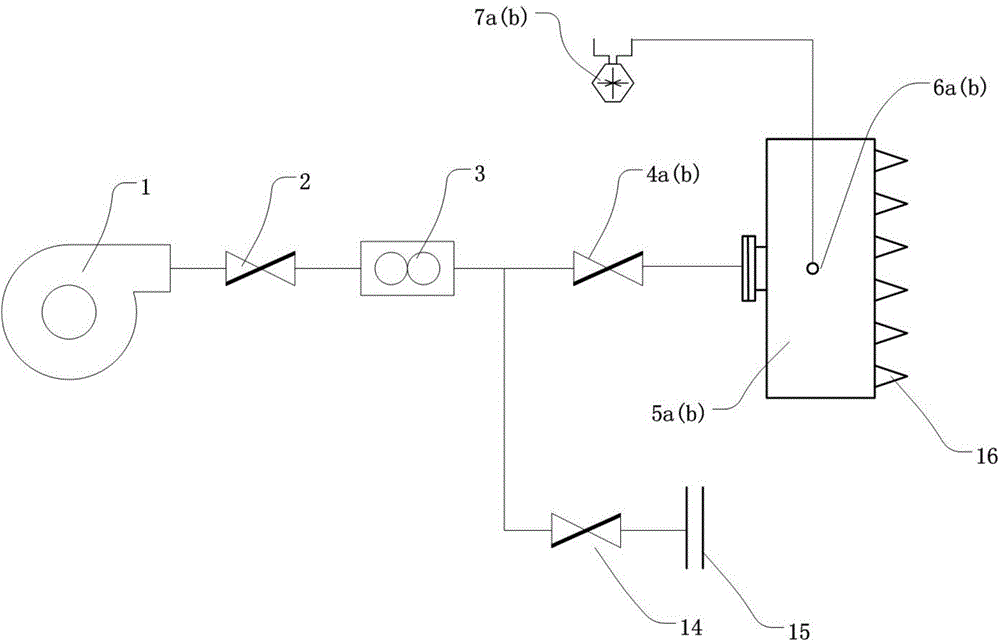

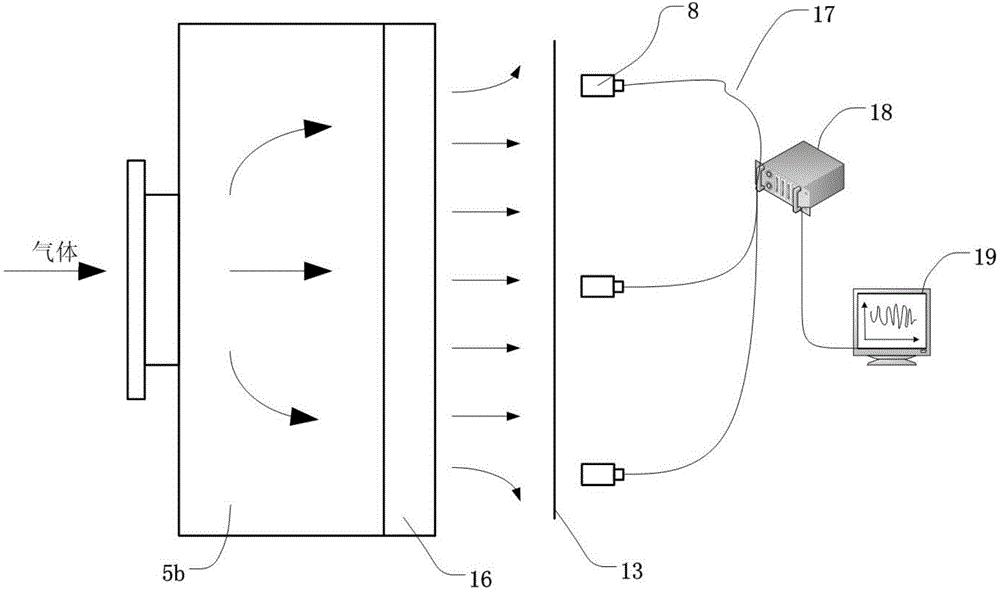

[0032] The system for measuring the vibration of strip steel in the gas cooling section of the present invention includes a gas injection system, a thin metal strip fixing system and a displacement measurement system, such as figure 1 shown.

[0033] The gas injection system includes a fan 1, a fan outlet regulating valve 2, an air duct manifold flowmeter 3, a left bellows inlet regulating valve 4a, a right bellows inlet regulating valve 4b, a left bellows 5a and a right bellows 5b. Left bellows 5a and right bellows 5b are respectively opened with a 6mm diameter left pressure-taking hole 6a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com