Rotor cage bar casting equipment and technology of submersible motor

A technology for submersible motors and casting equipment, applied in rotors, heat exchange equipment, stators, etc., can solve the problems of poor integrity of rotor components, large consumption of auxiliary materials, complex processes, etc., and achieve small dynamic balance, total cost reduction, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

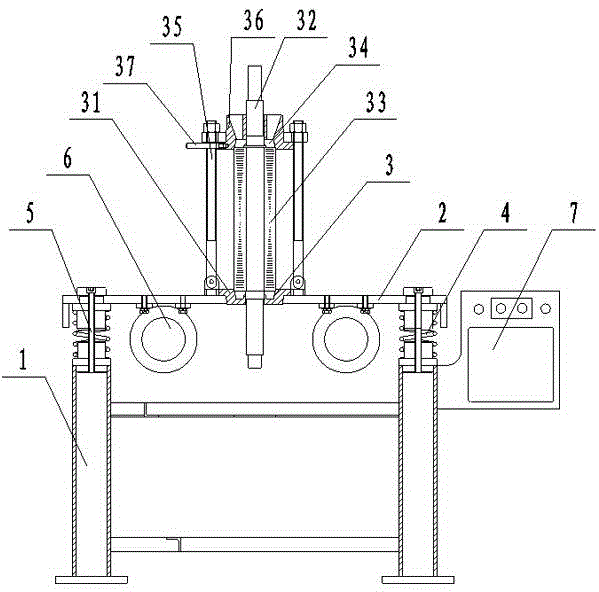

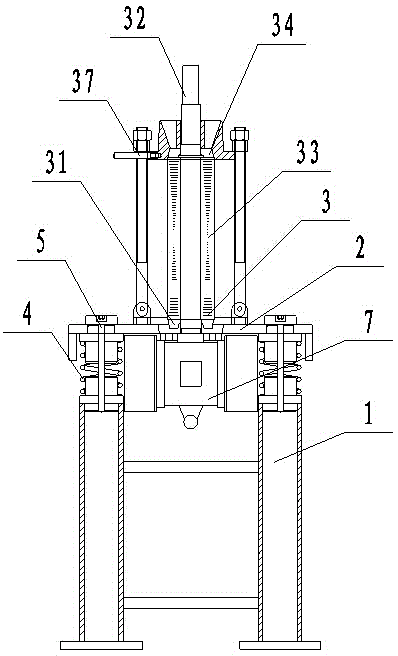

[0024] like figure 1 , figure 2 As shown, the submersible motor rotor cage bar casting equipment of the present invention includes a frame 1, a workbench 2, a mold assembly 3 and a spring 4, the workbench 2 is located above the frame 1, and the spring 4 is arranged on the workbench 2 Between and the frame 1, the workbench 2 can reciprocate up and down relative to the frame 1 by using the spring 4, and the bottom of the workbench 2 is provided with a vibration driving part 6 that provides power for the movement of the workbench 2, and the workbench Bolts 5 are provided on the four corners of the table 2, and the bolts 5 are used to position the workbench 2 on the frame 1 and limit the movement stroke of the workbench 2;

[0025] The mold assembly 3 is arranged on the top of the workbench 2, and the structure of the mold assembly 3 is: comprising a lower mold 31, a true shaft 32, a rotor core part 33, an upper mold 34 and connecting bolts 35, the lower mold 31 Set at the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com