Numerical control machine tool spindle intelligent cooling system and working process thereof

A technology of cooling system and CNC machine tool, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased energy consumption, expensive equipment, and inability to adjust cooling time, so as to reduce the cost of oil cooling and reduce the Effects of energy consumption and improvement of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

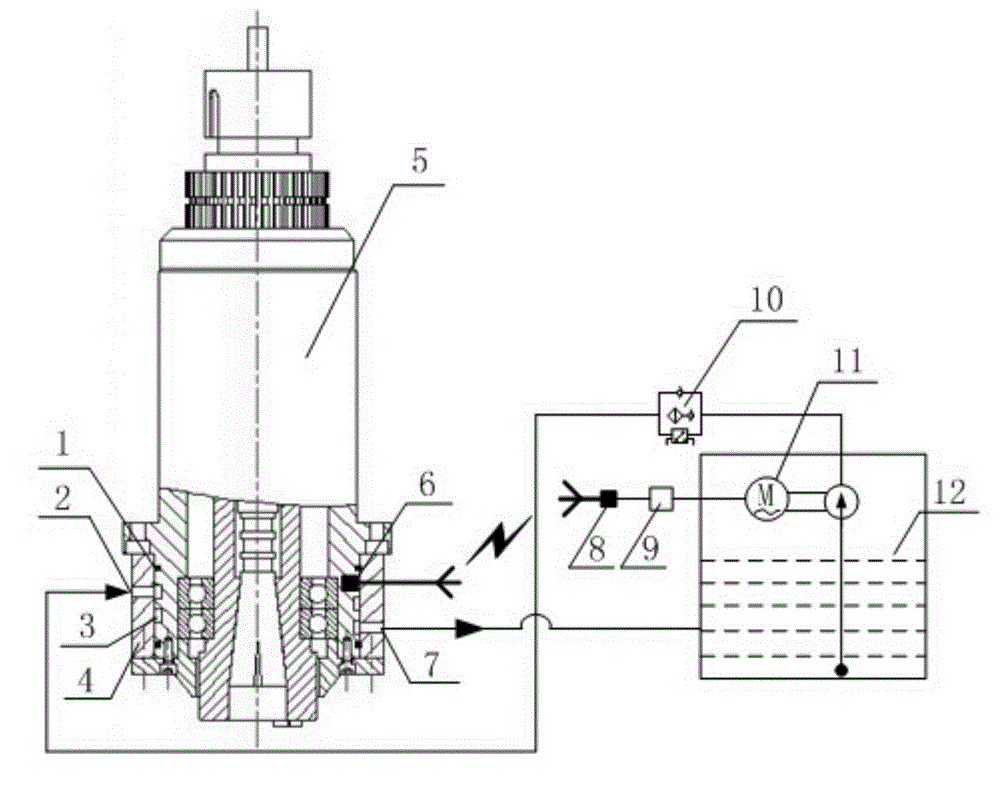

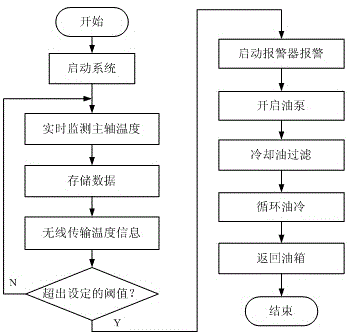

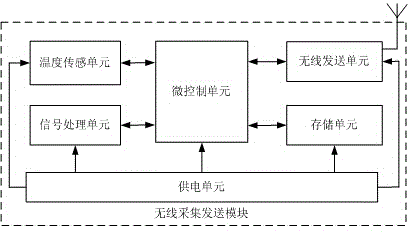

[0030] Such as figure 1 As shown, an intelligent cooling system for the spindle of a CNC machine tool: includes a spindle 5, a spiral groove 3, an oil cooling jacket 4, a sealing ring 1, an oil inlet 2, an oil outlet 7, a wireless temperature collection and sending module 6, a wireless receiving module 8. Oil pump controller 9, oil pump 11, filter 10 and oil tank 12. The spiral groove 3 is processed on the outer surface of the heat sensitive area of the spindle 5, and a spindle oil cooling jacket 4 is installed on the spindle 5. The spiral groove 3 cooperates with the oil cooling jacket 4 to form an annular oil path, the oil cooling jacket 4 An oil inlet 2 and an oil outlet 7 are respectively opened on the upper part, and the two ends are equipped with sealing rings 1 for sealing. A wireless temperature acquisition and sending module 6 is installed inside the main shaft 5 near the heat-sensitive area, and a wireless receiving module 8 is placed outside; the wireless receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com