Method for preparing porous graphene microspheres through high-speed mixing technology

A technology of porous graphene and high-speed stirring, which is applied in the field of preparation of porous graphene microbeads, can solve problems such as the inability to prepare porous graphene with spherical structure, and achieves the effect of increasing curing rate and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

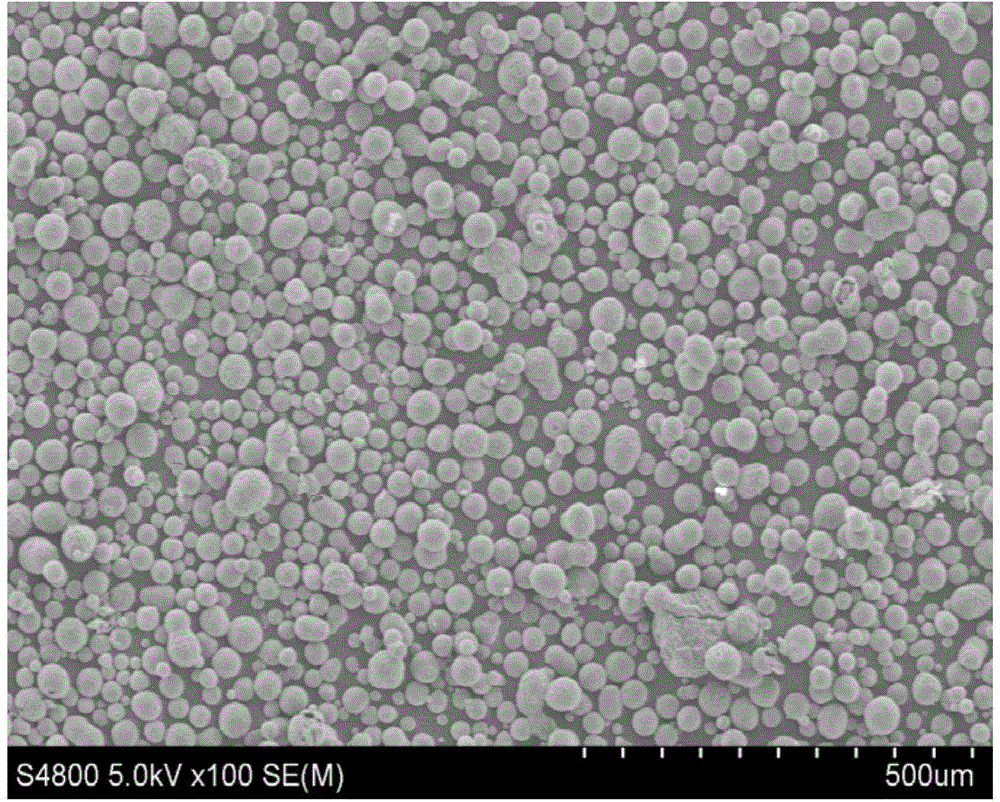

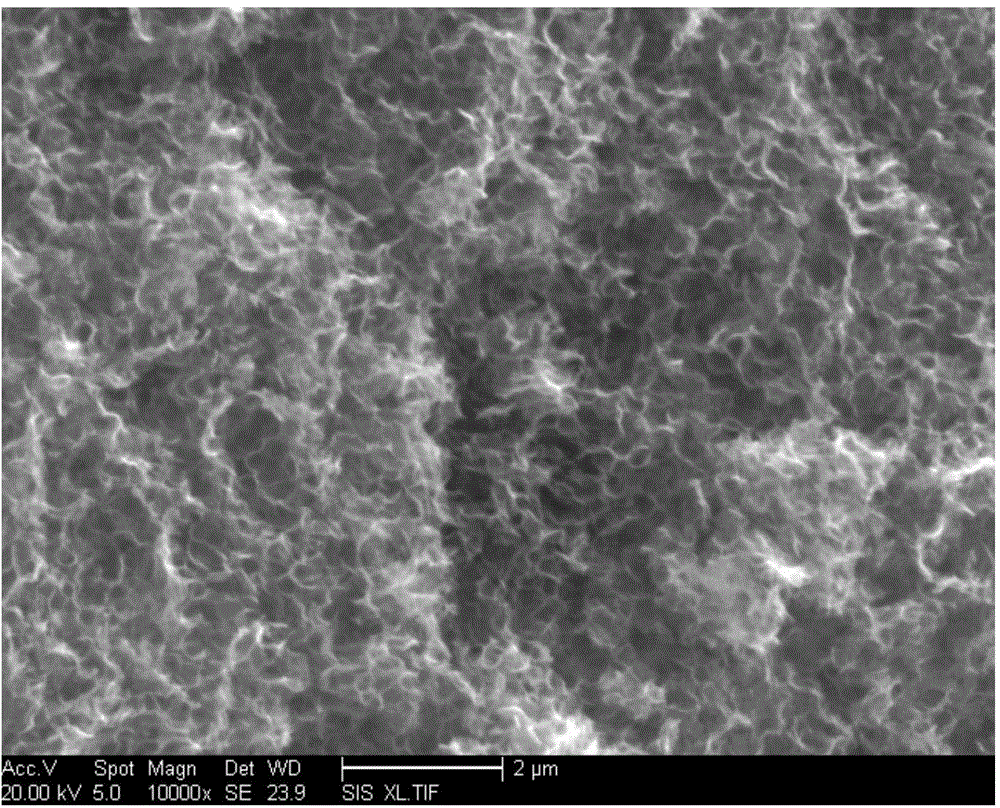

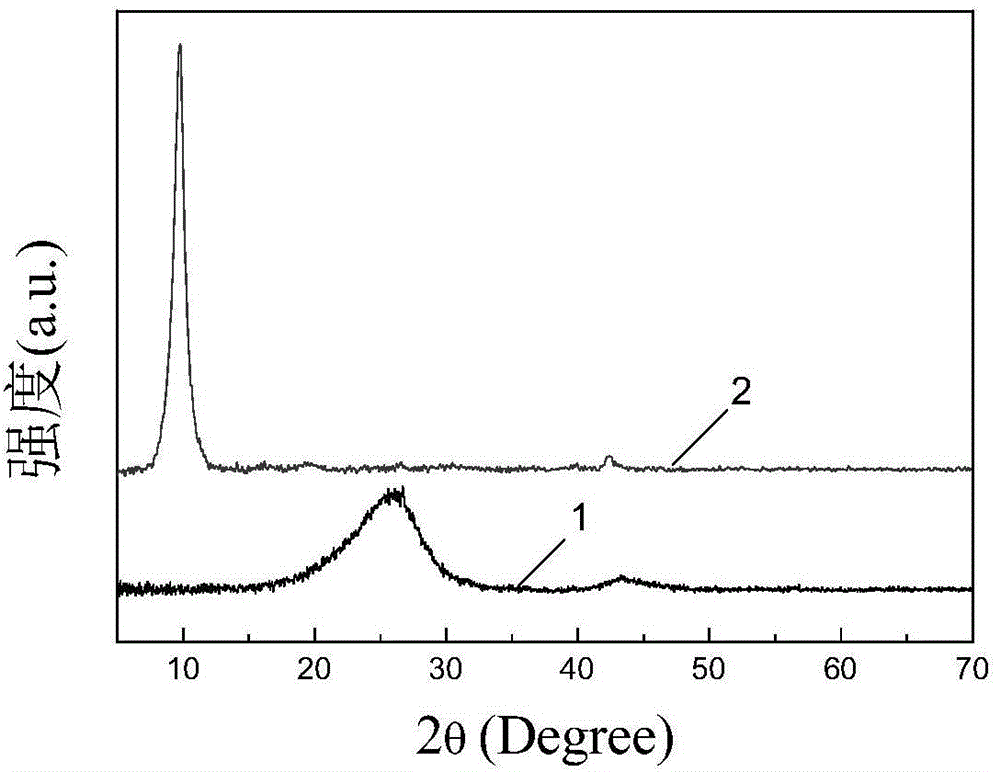

[0022] Specific embodiment one: a kind of method that utilizes high-speed stirring technology to prepare porous graphene microbead described in this embodiment, specifically is carried out according to the following steps:

[0023] 1. Mix polyvinylpyrrolidone powder, graphene oxide dry powder and silica microsphere dry powder to obtain a mixed powder, and then mix the mixed powder with deionized water to obtain a composite suspension;

[0024] The mass ratio of the polyvinylpyrrolidone powder to the graphene oxide dry powder is 1:(0.2~0.3); the mass ratio of the polyvinylpyrrolidone powder to the silica microsphere dry powder is 1:(0.5~1); The mass ratio of described mixed powder and deionized water is 1:(25~30);

[0025] 2. Add the composite suspension into a polypropylene microwave oven box filled with simethicone oil, stir magnetically for 2h-3h at a temperature of 80°C-90°C and a stirring speed of 400rpm-600rpm, and then solidify and form. Finally, stand and settle at roo...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of polyvinylpyrrolidone powder and graphene oxide dry powder described in step 1 is 1:(0.2-0.28). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of polyvinylpyrrolidone powder and silica microsphere dry powder described in step 1 is 1:(0.5-0.9). Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com