A kind of preparation method of porous graphene microbead

A technology of porous graphene and microbeads, which is applied in the field of preparing porous graphene microbeads, which can solve the problems that three-dimensional porous graphene microbeads have not yet been prepared, and achieve the effects of uniform diameter, broad application prospects, and improved curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

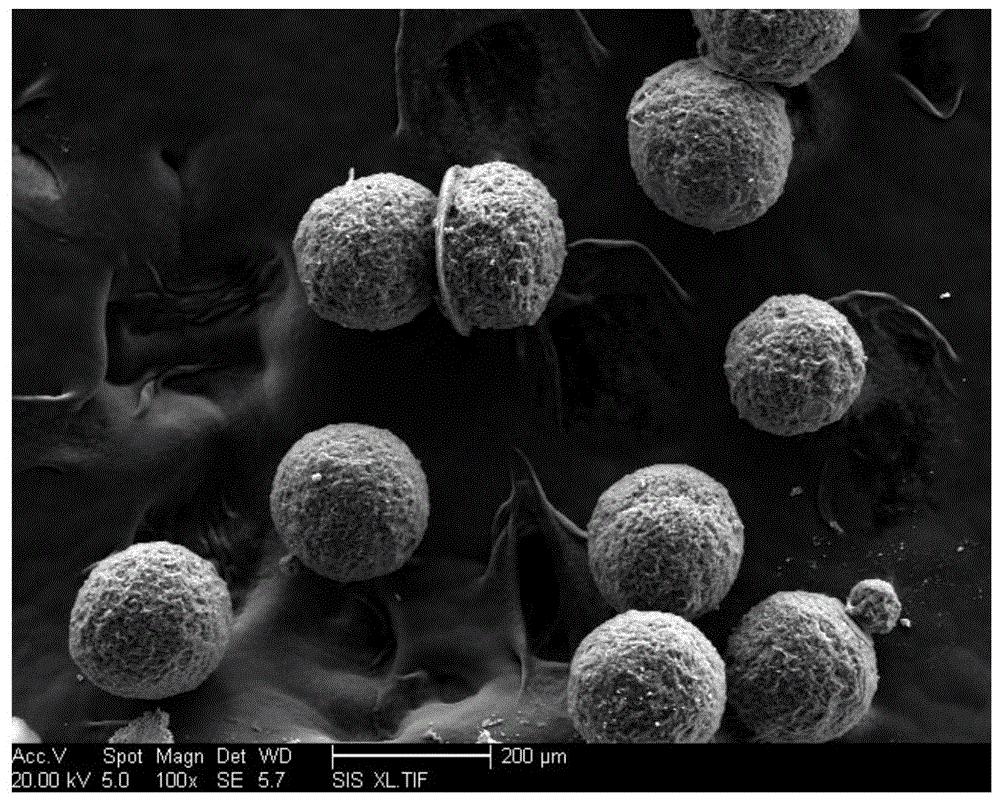

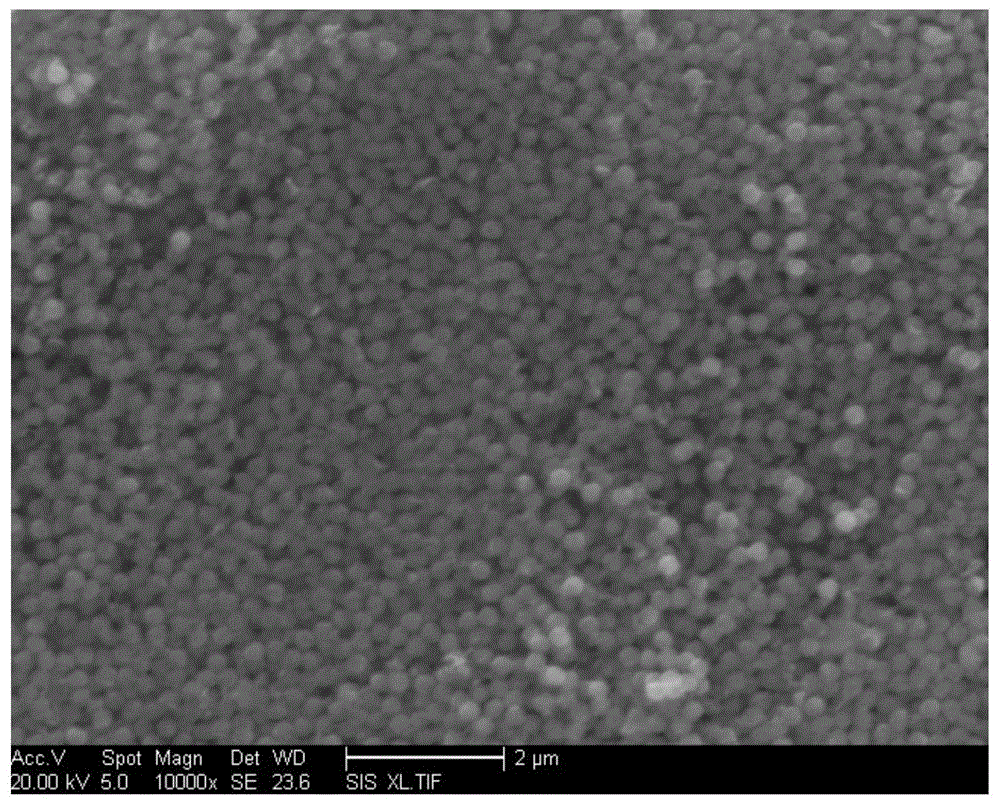

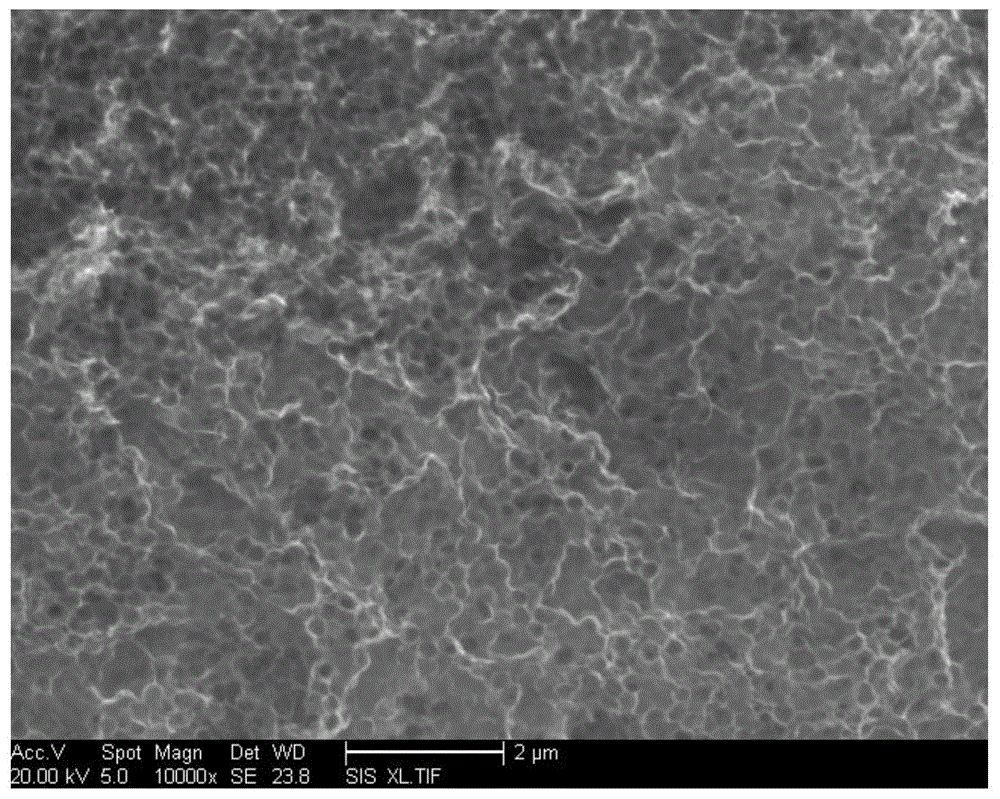

[0021] Specific embodiment one: a kind of method of utilizing the uniform dropwise addition method of present embodiment to prepare porous graphene microbead, carry out according to the following steps:

[0022] 1. Mix graphene oxide dry powder, polyvinylpyrrolidone powder and silica microsphere dry powder to obtain a mixture, then add deionized water to form a composite solution; wherein graphene oxide dry powder, polyvinylpyrrolidone powder and The mass ratio of silicon microsphere dry powder is 0.2:1:0.1~0.2, and the mass ratio of deionized water to mixture is 25:1;

[0023] 2. Pour the composite solution in step 1 into the syringe on the syringe pump and push it into the rotating round basin at a speed of 0.5-0.8mL / h, and directly heat and solidify to obtain composite microbeads; wherein, the The round basin contains simethicone oil;

[0024] 3. Dry the composite microbeads in step 2 at 100°C, and then pre-oxidize by step-by-step heating method; the step-by-step heating m...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of graphene oxide dry powder, polyvinylpyrrolidone powder and silica microsphere dry powder in step 1 is 0.2:1:0.15. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 in that the receiver used in step 2 is a round basin made of high-density polyethylene. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com