Leatherette paper with flame-retardant function and production method of leatherette paper

A leather-filled, functional technology, applied in paper, papermaking, textiles, and papermaking, can solve problems such as poor safety performance, and achieve the effects of good water resistance, good flame retardant function, and good moisture absorption resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

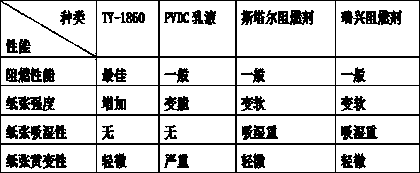

Method used

Image

Examples

Embodiment 1

[0040] The production method of white fine kraft grain flame-retardant leather-filled paper comprises the following steps:

[0041] (1) Production of base paper, base paper basis weight 85g / m 2 , Slurry ratio: softwood pulp 70% (total dry fiber content), chemical fiber 30% (total dry fiber content), wet strength agent PAE 2.5% (wet strength agent stock solution to total dry fiber content ). The coniferous wood pulp is Canadian Kelly Pu softwood pulp, the chemical fiber is 4mm short fiber produced by Japan Sojitz Corporation, and the PAE is the product of Shandong Zibo Jinli Chemical Co., Ltd. Slurry treatment only defrosts, without beating, to ensure that the fibers are not damaged and the length of the fibers is not lost. Produced by 1760mm fourdrinier multi-cylinder paper machine, the surface absorption weight of the produced base paper is 250-280g / m 2 , The paper machine production speed is 160m / min.

[0042] (2) Impregnating flame retardant treatment: Weigh 20kg of TY-18...

Embodiment 2

[0048] The production method of red certificate pattern flame-retardant leather-filled paper comprises the following steps:

[0049] (1) Production of base paper, base paper basis weight 100g / m 2 , Slurry ratio: softwood pulp 70% (total dry fiber content), chemical fiber 30% (total dry fiber content), wet strength agent PAE 2.5% (wet strength agent stock solution to total dry fiber content ). The coniferous wood pulp is Canadian Kelly Pu softwood pulp, the chemical fiber is 4mm short fiber produced by Japan Sojitz Corporation, and the PAE is the product of Shandong Zibo Jinli Chemical Co., Ltd. Slurry treatment only defrosts, without beating, to ensure that the fibers are not damaged and the length of the fibers is not lost. Produced by 1760mm fourdrinier multi-cylinder paper machine, the surface absorption weight of the produced base paper is 250-280g / m 2 , The paper machine production speed is 160m / min.

[0050] (2) Impregnating flame retardant treatment: Weigh 20kg of T...

Embodiment 3

[0056] The difference between the test conditions of this example and Example 1 is: between steps (2) and (3), it also includes calendering and finishing the paper obtained in step 2 through a light press, wherein the pressure is 8MPa, The vehicle speed is 50m / min, and the pressurization temperature is room temperature (20 degrees Celsius). The weight per square meter of the finally obtained leather filled paper was 142 grams. In this test, it was found that the amount of latex used was significantly lower than that of Example 1, and the adsorption amount of latex decreased significantly, and the impregnation amount was 14.6 g per square meter. The pressurization process is realized on the paper roll by extrusion with a special ring extrusion die.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com