Strippable double-sided sticky tape for large-size sapphire glass grinding and preparation method of strippable double-sided sticky tape

A technology of sapphire glass and double-sided tape, applied in the direction of adhesive, adhesive type, film/flake adhesive, etc., can solve the problems of difficult to take out sapphire, cumbersome process, affecting processing efficiency, etc., to facilitate industrial production , The method steps are simple, and the effect of improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

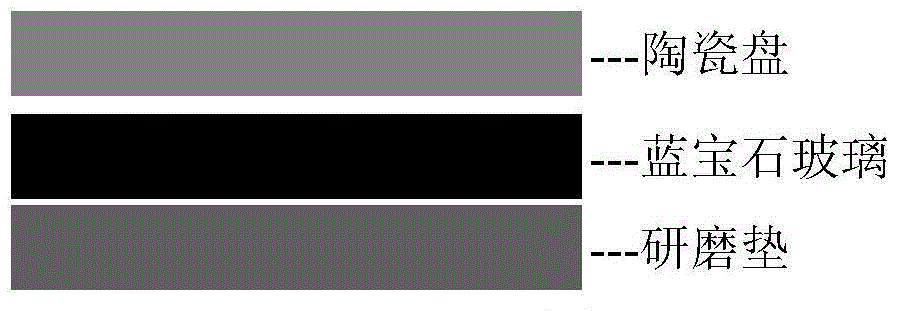

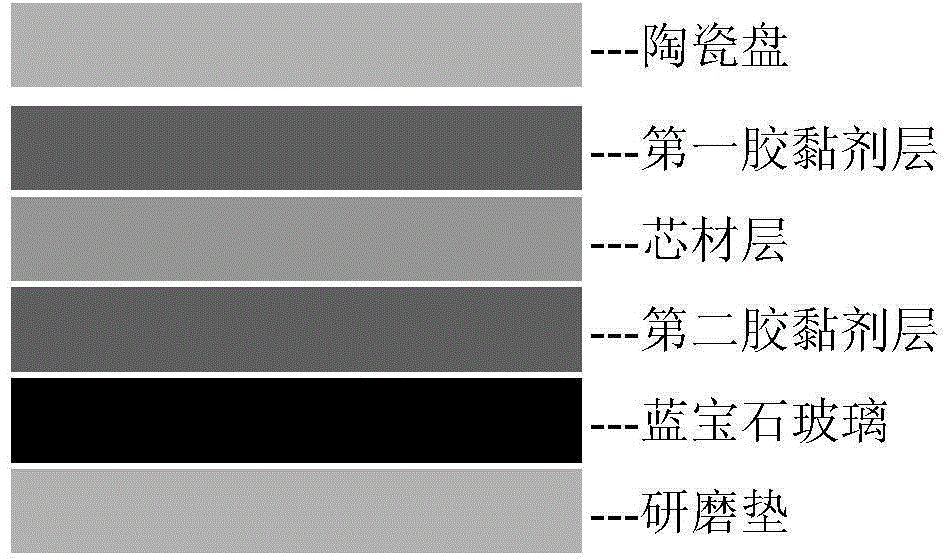

[0038] In this embodiment, the peelable double-sided adhesive tape for grinding large-size sapphire glass includes a first release layer, a first adhesive layer, a core material layer, a second adhesive layer and a second release layer that are sequentially compounded, wherein ,

[0039] The first adhesive layer comprises the following components by weight:

[0040] Heavy-duty acrylic adhesive body SK-15 100 parts,

[0041] 1 part of isocyanate crosslinking agent TDI;

[0042] The second adhesive layer comprises the following components by weight:

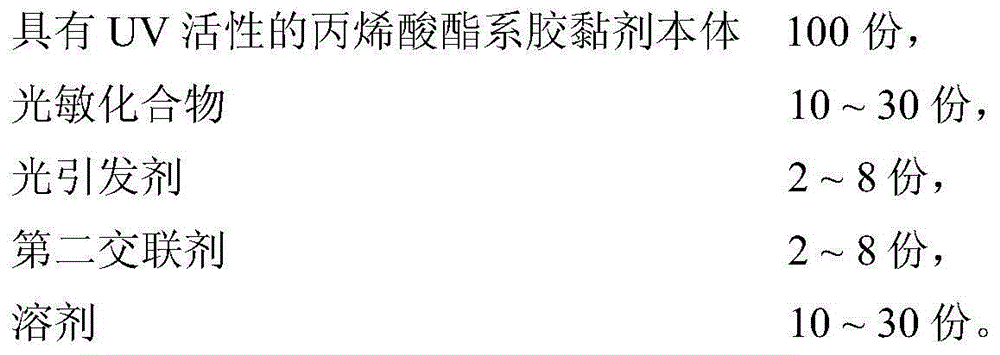

[0043]

[0044] The core material layer is a PET film with a thickness of 6 μm.

[0045] The preparation method of the above-mentioned large-size sapphire glass grinding peelable double-sided tape comprises the following steps:

[0046] (1) Add 1 part of isocyanate-based crosslinking agent TDI to 100 parts of heavy-duty acrylate adhesive body SK-15, and stir evenly to obtain the composition of the first adhesive layer;

[004...

Embodiment 2

[0053] In this embodiment, the peelable double-sided adhesive tape for grinding large-size sapphire glass includes a first release layer, a first adhesive layer, a core material layer, a second adhesive layer and a second release layer that are sequentially compounded, wherein ,

[0054] The first adhesive layer comprises the following components by weight:

[0055] Heavy-duty acrylic adhesive body SK-15 100 parts,

[0056] 2 parts of isocyanate crosslinking agent TDI;

[0057] The second adhesive layer comprises the following components by weight:

[0058]

[0059] The core material layer is a PET film with a thickness of 8 μm.

[0060] The preparation method of the above-mentioned large-size sapphire glass grinding peelable double-sided tape comprises the following steps:

[0061] (1) Add 2 parts of isocyanate-based crosslinking agent TDI to 100 parts of heavy-duty acrylic adhesive body SK-15, and stir evenly to obtain the composition of the first adhesive layer;

[...

Embodiment 3

[0068] In this embodiment, the peelable double-sided adhesive tape for grinding large-size sapphire glass includes a first release layer, a first adhesive layer, a core material layer, a second adhesive layer and a second release layer that are sequentially compounded, wherein ,

[0069] The first adhesive layer comprises the following components by weight:

[0070] Heavy-duty acrylic adhesive body SK-15 100 parts,

[0071] 3 parts of isocyanate crosslinking agent HMDI;

[0072] The second adhesive layer comprises the following components by weight:

[0073]

[0074] The core material layer is a PET film with a thickness of 10 μm.

[0075] The preparation method of the above-mentioned large-size sapphire glass grinding peelable double-sided tape comprises the following steps:

[0076] (1) Add 3 parts of isocyanate-based crosslinking agent HMDI to 100 parts of heavy-duty acrylate adhesive body SK-15, and stir evenly to obtain the composition of the first adhesive layer; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com