Heat-resistance phenolic resin adhesive for chemical resistant laminate

A technology of phenolic resin glue and phenolic resin, applied in the direction of adhesives, adhesive additives, carboxyl rubber adhesives, etc., can solve the problem of insufficient thermal stability of phenolic resin, insufficient service life, low impact strength of physical and chemical boards, etc. problems, achieve good fluidity and storage stability, long service life, and obvious toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

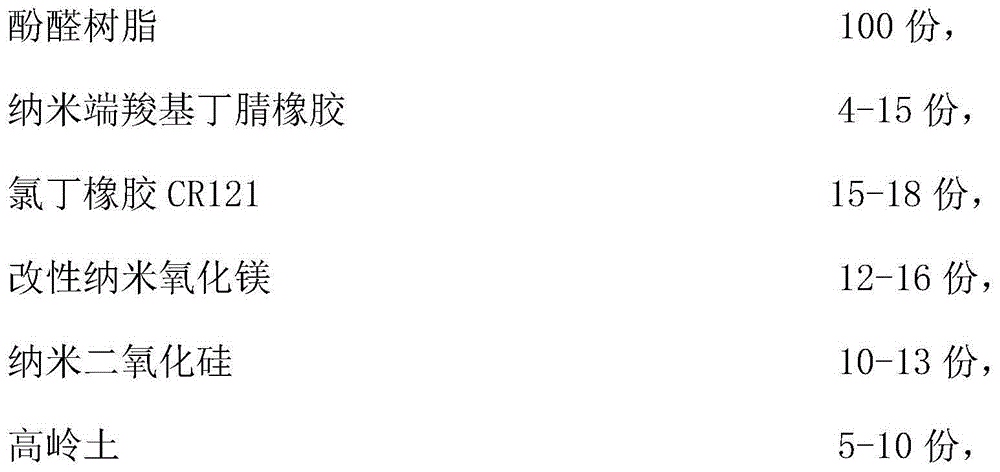

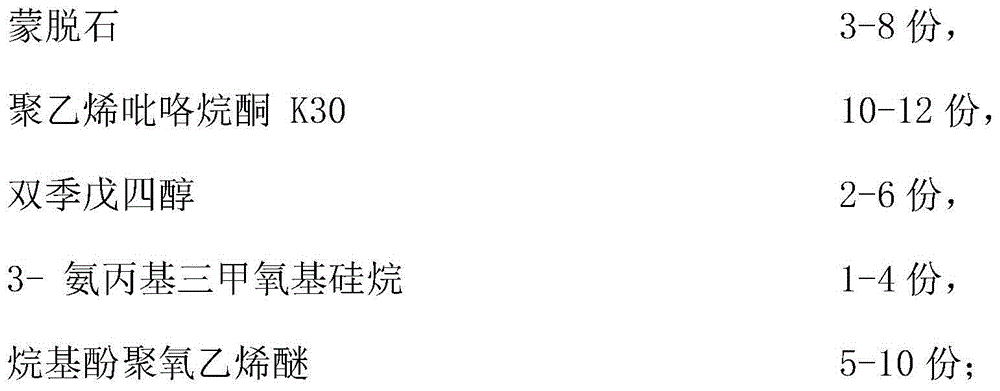

[0020] A heat-resistant phenolic resin adhesive for physical and chemical boards proposed by the present invention, its raw materials include by weight:

[0021]

[0022] In the preparation process of modified nano-magnesia, add 20 parts by weight of nano-magnesia to 80 parts of absolute ethanol for an ultrasonic dispersion for 2 hours. After heating up to 70°C, carry out ultrasonic dispersion for 5 minutes twice, cool down to 55°C, add 1 part of dicumyl peroxide, carry out ultrasonic dispersion for 40 minutes three times, then reflux at 80°C for 40 minutes, filter, and centrifuge to obtain modified nano-magnesium oxide;

[0023] In the nano-carboxyl-terminated nitrile rubber, the particle size is 10-20nm, which accounts for 5wt%, the particle size is 20-50nm, which accounts for 80wt%, and the remaining particle size is 50-70nm; in the modified nano-magnesia, the particle size is 1-4nm. 10wt%, the particle size is 5-8nm, accounting for 80wt%, and the remaining particle size...

Embodiment 2

[0025] A heat-resistant phenolic resin adhesive for physical and chemical boards proposed by the present invention, its raw materials include by weight:

[0026]

[0027] In the preparation process of modified nano-magnesia, add 30 parts of nano-magnesia to 70 parts of absolute ethanol by weight to carry out ultrasonic dispersion for 1 hour. After heating up to 60°C, carry out ultrasonic dispersion for 15 minutes twice, cool down to 45°C, add 2 parts of dicumyl peroxide, carry out ultrasonic dispersion for 3 times for 20 minutes, then reflux at 90°C for 30 minutes, filter, and centrifuge to obtain modified nano-magnesium oxide;

[0028] Among them, in the nano-carboxylated nitrile rubber, the particle size is 10-20nm, accounting for 15wt%, the particle size is 20-50nm, accounting for 70wt%, and the remaining particle size is 50-70nm; in the modified nano-magnesia, the particle size is 1-4nm Accounting for 15wt%, the particle size of 5-8nm accounts for 50wt%, and the rest of...

Embodiment 3

[0030] A heat-resistant phenolic resin adhesive for physical and chemical boards proposed by the present invention, its raw materials include by weight:

[0031]

[0032] In the preparation process of modified nano-magnesia, 25 parts of nano-magnesia was added to 75 parts of absolute ethanol by weight to carry out ultrasonic dispersion for 1.5 hours. After heating up to 64°C, perform ultrasonic dispersion twice for 10 minutes, cool down to 52°C and add 1.6 parts of dicumyl peroxide for three times ultrasonic dispersion for 32 minutes, then reflux at 86°C for 35 minutes, filter, and centrifuge to obtain modified nano-magnesia ;

[0033] Among them, in the nano-carboxyl-terminated nitrile rubber, the particle size is 10-20nm, accounting for 10wt%, the particle size is 20-50nm, accounting for 75wt%, and the remaining particle size is 50-70nm; in the modified nano-magnesia, the particle size is 1-4nm Accounting for 13wt%, the particle size of 5-8nm accounts for 70wt%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap