Composition for fracturing fluid drag reducer

A composition and compound technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as the narrow temperature range of drag reducers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

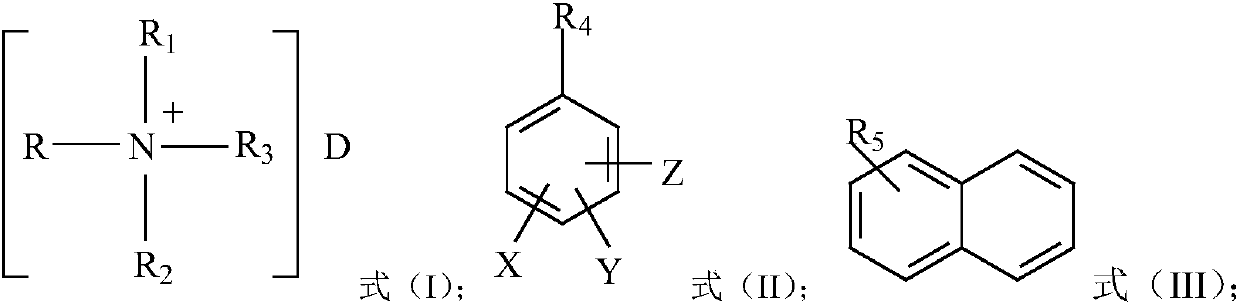

Method used

Image

Examples

Embodiment 1

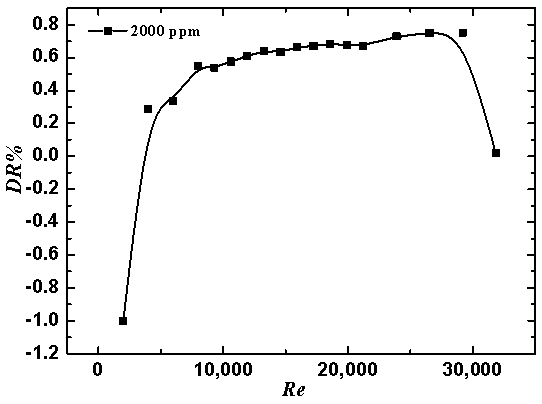

[0040] Add 0.5mol hexadecane bromide, 0.75mol N-methyldiethanolamine, and 300g absolute ethanol together into a 2000ml reaction flask equipped with a sealed mechanical stirrer, a thermometer, a straight condenser tube, and a receiving flask. 100°C, the reaction was refluxed for 16h. The product obtained was cooled down and recrystallized in absolute ethanol to obtain a white solid, which was confirmed as the target product N-methyl-N, N-di(2-hydroxyethyl)-1-hexadecylammonium bromide by mass spectrometry[ MS-ESI (m / z): theoretical, 424; actual, 344 (M-Br)]. N,N-Dimethyl-N-(2-hydroxyethyl)-1-hexadecylammonium bromide and sodium salicylate are mixed in equal mass ratio. Dissolve it in water to prepare a 2000ppmw drag reducing agent aqueous solution, and keep it clear and transparent without precipitation for 7 days at 2°C. Test the drag reduction rate at different temperatures, the highest drag reduction rate can be maintained at 73%. figure 1 It is the drag reduction rate cur...

Embodiment 2

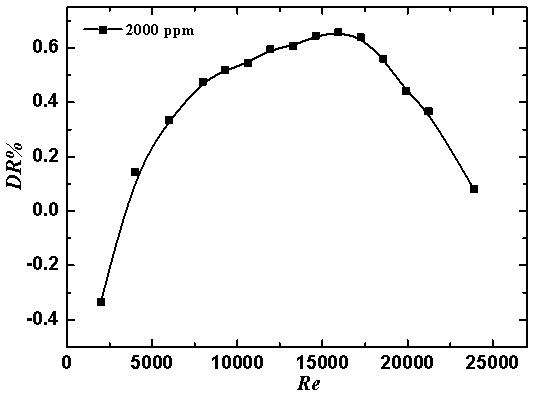

[0042] Add 0.5mol hexadecane bromide, 0.75mol N-methyldiethanolamine, and 300g absolute ethanol together into a 2000ml reaction flask equipped with a sealed mechanical stirrer, a thermometer, a straight condenser tube, and a receiving flask. 100°C, the reaction was refluxed for 16h. The product obtained was cooled down and recrystallized in absolute ethanol to obtain a white solid, which was confirmed as the target product N-methyl-N, N-di(2-hydroxyethyl)-1-hexadecylammonium bromide by mass spectrometry[ MS-ESI (m / z): theoretical, 424; actual, 344 (M-Br)]. The prepared cationic surfactant and sodium salicylate were dissolved in water to prepare a 2000ppmw drag reducer aqueous solution, which was kept clear and transparent at 2°C for 7 days without precipitation. Test the drag reduction rate at different temperatures, the highest drag reduction rate can be maintained at 70%. The applicable temperature range is 2~60℃.

Embodiment 3

[0044] Add 0.5mol hexadecane bromide, 0.75mol triethanolamine, and 300g absolute ethanol together into a 2000ml reaction bottle equipped with a sealed mechanical stirrer, a thermometer, a straight condenser tube, and a receiving bottle. The temperature of the oil bath is 100°C. Reflux for 16h. The obtained product was cooled down and recrystallized in absolute ethanol to obtain a white solid, which was confirmed by mass spectrometry as the target product N,N,N-tris(2-hydroxyethyl)-1-hexadecylammonium bromide [MS-ESI (m / z): theoretical value, 454; actual value, 374 (M-Br)]. The prepared cationic surfactant and sodium salicylate were dissolved in water to prepare a 2000ppmw drag reducer aqueous solution, which was kept clear and transparent at 2°C for 7 days without precipitation. Test the drag reduction rate at different temperatures, the highest drag reduction rate can be maintained at 70%. The applicable temperature range is 2~55℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com