Technological method and system for enzymatically synthesizing L-ascorbic acid 2-glucoside

A technology of ascorbic acid and process system, which is applied in the field of enzyme-catalyzed synthesis of L-ascorbic acid 2-glucoside and can solve the problem of low purity, low yield and difficult removal of impurities, etc. problem, to achieve the effect of high product purity, stable and uniform crystal form, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

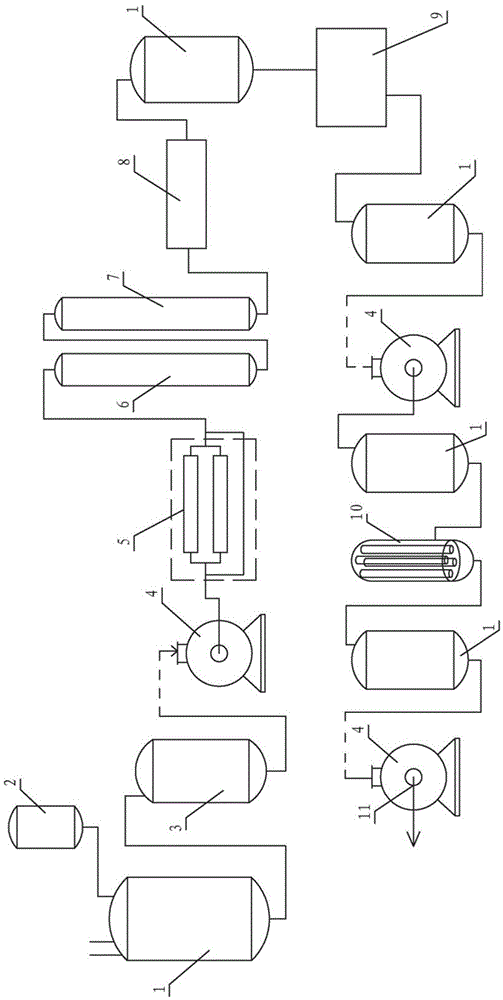

[0043] Such as figure 1 , a process system for enzyme-catalyzed synthesis of L-ascorbic acid 2-glucoside, characterized by: comprising a reaction kettle 1, an enzyme storage tank 2, a storage tank 3, a centrifuge 4, a first filter device 5, and a first resin column 6 , the second resin column 7, the second filter device 8, the falling film concentration device 9, the third filter device 10, the discharge port 11; the first filter device 5 is located at the upstream of the first resin column 6, the The downstream of the first resin column 6 is the second resin column 7, the second filter device 8 is located downstream of the second resin column 7, and the falling film concentration device 9 is located at the second filter device 8 Downstream; the third filter device 10 is positioned at the downstream of the falling film concentration device 9; the centrifuge 4 has multiple groups, respectively upstream of the first filter device 5 and the third filter device 10 Upstream of and...

Embodiment 2

[0046]Add 20KG of drinking water to the 1000L reactor, then add 6.5KG of vitamin C, and stir; use hot water to control the internal temperature of the reactor to 37°C; use 30% NaOH solution to adjust the pH to 5.4; add β-cyclodextrin to the reactor 14KG, then add 4.0KG of CGT enzyme, add drinking water to make the system quantified to 65KG; control the temperature in the reactor at 37±2℃, and react in the dark for 10h; add 70g of glucoamylase (enzyme solution 750,000 U / ml), and control the temperature 37±2℃, avoid light for 10h.

[0047] After the reaction is completed, discharge the material, wash the reactor with 2.0KG of drinking water, combine the reaction solution and the water for washing the kettle, weigh, and centrifuge through a butterfly centrifuge, wash the centrifuge with 2.0KG of drinking water; pass the obtained filtrate through an ultra The filter is used for ultrafiltration. During the ultrafiltration process, 30.0KG of drinking water is added for ultrafiltrati...

Embodiment 3

[0050] Add 20KG of drinking water to the 1000L reactor, then add 6.5KG of vitamin C, and stir; use hot water to control the internal temperature of the reactor to 37°C; use 30% NaOH solution to adjust the pH to 5.4; add β-cyclodextrin to the reactor 14KG, then add 4.0KG of CGT enzyme, add drinking water to make the system quantified to 65KG; control the temperature in the reactor at 37±2℃, and react in the dark for 10h; add 70g of glucoamylase (enzyme solution 750,000 U / ml), and control the temperature 37±2°C, protected from light for 14 hours.

[0051] After the reaction is completed, discharge the material, wash the reactor with 2.0KG of drinking water, combine the reaction solution and the water for washing the kettle, weigh, and centrifuge through a butterfly centrifuge, wash the centrifuge with 2.0KG of drinking water; pass the obtained filtrate through an ultra The filter is used for ultrafiltration. During the ultrafiltration process, 30.0KG of drinking water is added f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com