High-purity aluminum directional solidification short-process purification equipment and purification method

A directional solidification, short process technology, applied in the direction of improving process efficiency, can solve the problems of prolonged production cycle, low purification efficiency, low heating and cooling efficiency, etc., to achieve high purification efficiency and purification quality, process configuration optimization, The effect of increasing the melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

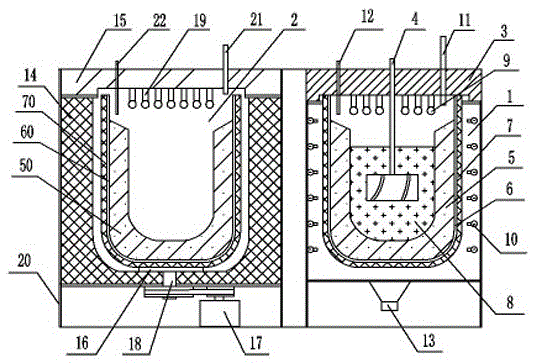

[0027] Embodiment 1: see figure 1, a high-purity aluminum directional solidification short-process purification equipment, including a purification device 1 and a heating device 2, the purification device 1 and the heating device 2 are independent, and are jointly arranged inside a large smelting furnace shell 20, and the purification device 1 is from outside to inside It includes a cooling device 10, a heat-conducting layer 7 for purification, a heat-retaining crucible for purification 6 and a stirring device 4 in sequence. A purifying furnace cover 3 is provided directly above the purifying and heat-retaining crucible 6. A vacuuming device 11 and a measuring chamber are respectively provided on both sides of the purifying furnace cover 3. The temperature device 12 is symmetrically provided with a first heating mechanism 9 below the purification furnace cover 3, and the stirring device 4 is located at the axis of the purification furnace cover 3 and can rotate horizontally. T...

Embodiment 2

[0029] Embodiment 2: the purification method of purifying by adopting the high-purity aluminum directional solidification short flow purification equipment described in embodiment 1, its specific steps are as follows:

[0030] ① Pour the refined molten aluminum into the purification and heat preservation crucible 6 in the purification device 1, close the purification furnace cover 3, open the stirring device 4 to stir the melt, and start the vacuuming device 11 to make the purification and heat preservation crucible 6 form vacuum;

[0031] ② When the original molten aluminum melt starts to solidify, power on the first heating mechanism 9, and slowly increase the power, control the melt temperature between 660°C and 680°C through the temperature measuring device 12, and use the cooling device 10 to purify the heat conducting layer 7 Carry out forced cooling, control the temperature gradient of the solid-liquid interface of the melt in the purification insulation crucible 6 to b...

Embodiment 3

[0038] Example 3: Select 2000Kg of refined primary aluminum liquid with a purity of at least 99.85% and a temperature of 700°C, and introduce it into the purification insulation crucible of the purification device, seal the purification device, start the vacuum device, and make the vacuum degree reach 10 -3 , turn on the stirring device to rotate the melt, and keep the number of revolutions at 15-50 rpm; start the heating device, and keep the power at 10-50kw to ensure that the melt temperature is cooled at a constant rate of 1°C / min, so that the melt temperature is kept at 660°C, the cooling device starts to automatically adjust the cooling, maintain the side crystallization speed of 5cm / h, and the crystallization ends after 3 hours; take out the purification insulation crucible, pour out the remaining aluminum liquid in it, and then put the purification insulation crucible together with the purified aluminum solid Put it into the heating device and seal it tightly, and evacua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com