Fragrant cotton blank and preparing method thereof

A technology of aromatic cotton tires and cotton tires, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as stinky smell, musty smell, knotting, etc., to improve comfort, improve elasticity and breathability, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

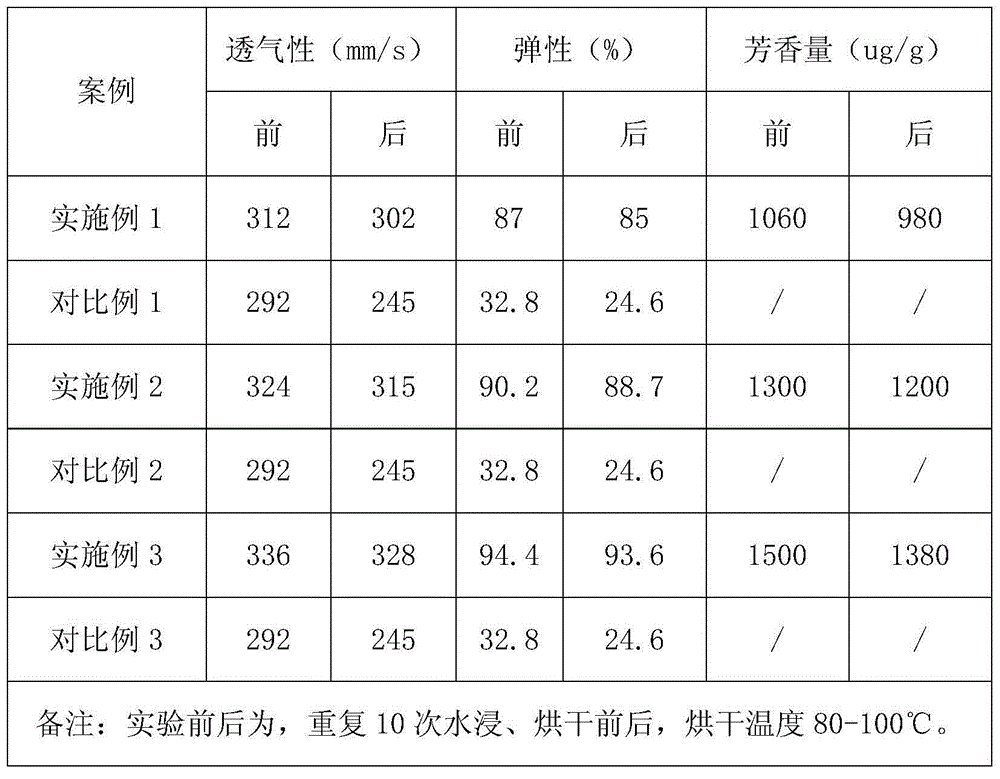

Examples

Embodiment 1

[0041] Aromatic cotton tire, the mass ratio of components is:

[0042] Jiangsu Lanpin Fiber Technology Development Co., Ltd. produces 10% nano-rose-flavored Lucca fiber, 10% Huvis low-melting fiber, and 80% cotton.

[0043] The aromatic fiber has a fineness of 7D and a length of 64mm;

[0044] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51mm;

[0045] Cotton is three-level national reserve lint.

[0046] The preparation method of fragrant cotton tire, comprises the steps:

[0047] Step 1: Weigh the aromatic fiber, low melting point fiber and cotton according to the mass ratio of the designed cotton tire components and mix them evenly to obtain the mixed material;

[0048] Step 2: After opening, removing impurities, and carding the mixed material into sheets, the sheets are laminated to form raw cotton flakes, the thickness of which is 12 cm; the opening, removing impurities, and carding are carried out by conventional processes...

Embodiment 2

[0056] Aromatic cotton tire, the mass ratio of components is:

[0057] Jiangsu Lanpin Fiber Technology Development Co., Ltd. produces 20% of nano rose-scented Lucca fiber aromatic fiber, 15% of Huvis low-melting fiber, and 65% of cotton.

[0058] Aromatic fibers have a denier of 3D and a length of 38 mm;

[0059] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51 mm;

[0060] Cotton is three-level national reserve lint.

[0061] The preparation method of fragrant cotton tire, comprises the steps:

[0062] Step 1: Weigh the aromatic fiber, low melting point fiber and cotton according to the mass ratio of the designed cotton tire components and mix them evenly to obtain the mixed material;

[0063] Step 2: After opening, removing impurities, and combing the mixed material into sheets, the sheets are laminated to form raw cotton flakes, and the thickness of the raw cotton flakes is 15 cm; the opening, removing impurities, and carding ...

Embodiment 3

[0070] Aromatic cotton tire, the mass ratio of components is:

[0071] Jiangsu Lanpin Fiber Technology Development Co., Ltd. produces nano rose-scented Lucca fiber aromatic fiber 27%, Huvis low-melting fiber 13%, cotton 60%,

[0072] The aromatic fiber has a fineness of 7D and a length of 64 mm;

[0073] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51 mm;

[0074] Cotton is three-level national reserve lint.

[0075] The preparation method of fragrant cotton tire, comprises the steps:

[0076] Step 1: Weigh the aromatic fiber, low melting point fiber and cotton according to the mass ratio of the designed cotton tire components and mix them evenly to obtain the mixed material;

[0077] Step 2: After opening, removing impurities, and carding the mixed material into sheets, the sheets are laminated to form raw cotton flakes, the thickness of which is 12 cm; the opening, removing impurities, and carding are carried out by convention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com