A dynamic feedback measurement and control platform for research on fabric drying technology in clothes dryers

A technology of dynamic feedback and clothes dryers, which is applied to household clothes dryers, applications, household appliances, etc., can solve the problems of waste of manpower and material resources, poor versatility of drying models, and lack of understanding of thermal mass changes, etc., to improve accuracy, Realize the effect of real-time automatic monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

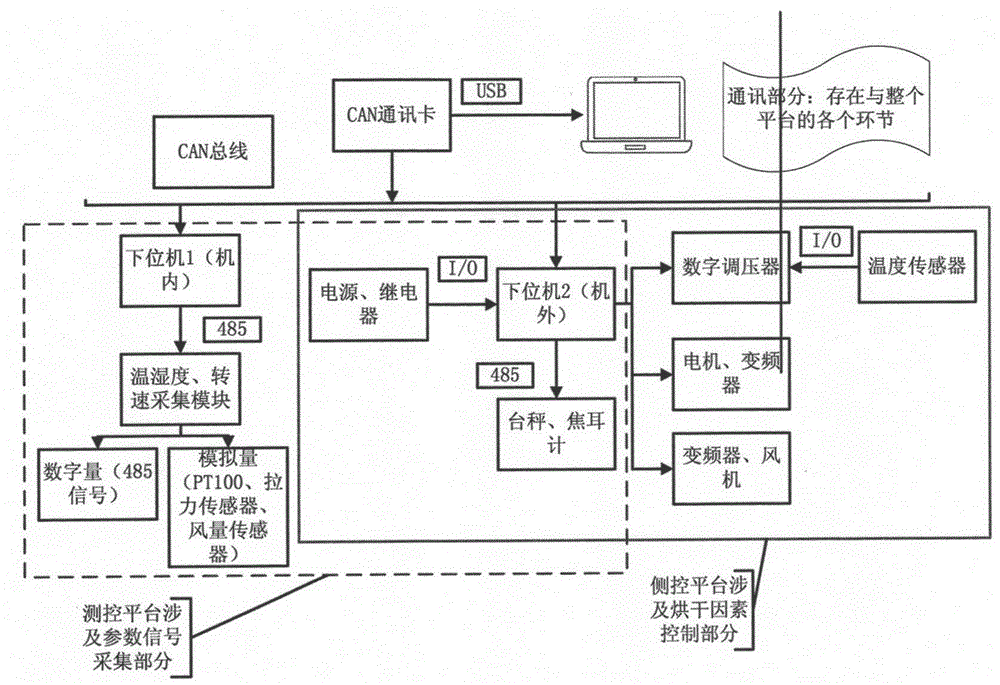

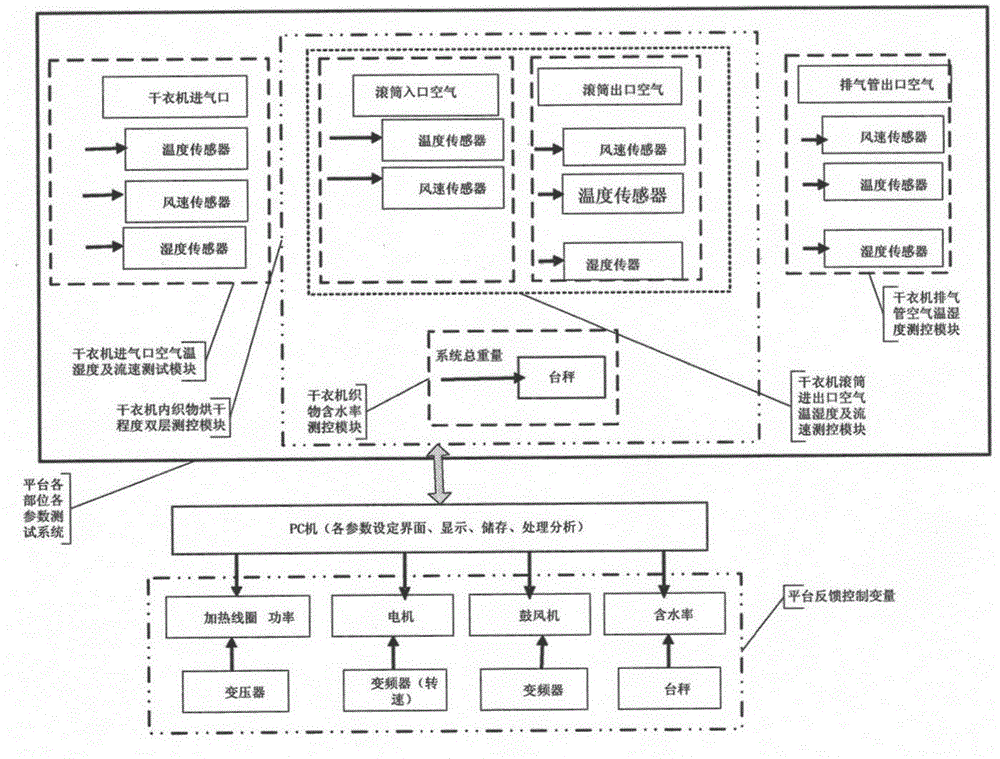

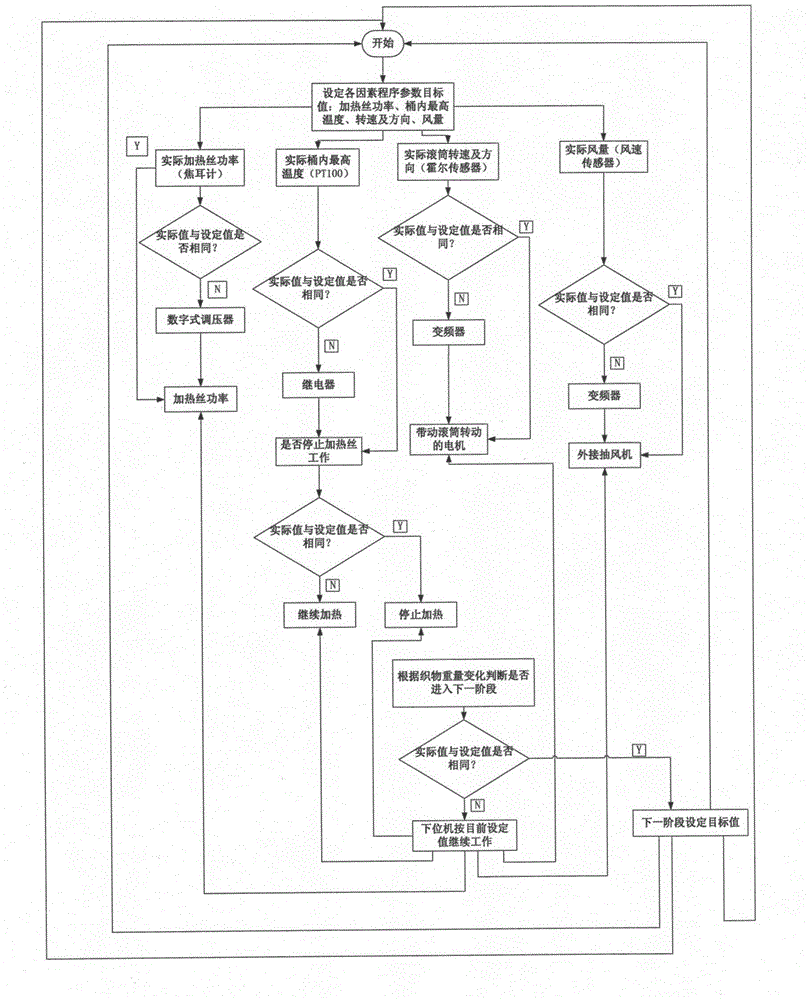

[0028] combine figure 1 , a dynamic feedback measurement and control platform used in the research of fabric drying technology in a clothes dryer provided by the present invention mainly includes three parts: the various parameter signal acquisition parts involved in the measurement and control platform, and the control of various factors involved in the measurement and control platform. Part, the communication part connecting the acquisition system and the control system. The parameters collected by the various parameter collection parts involved in the measurement and control platform include: 1) the temperature, humidity and flow rate of the air at the air inlet of the dryer; 2) the temperature and humidity of the air at the entrance of the drum; 3) the temperature and humidity of the air at the outlet of the drum and Flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com