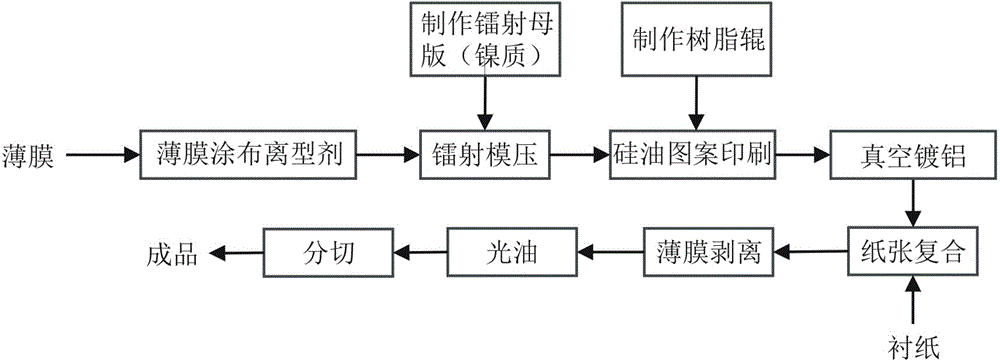

Production process with local pattern vacuum aluminum plating and lasering multiple anti-counterfeiting lining paper for cigarettes

A technology of vacuum aluminum plating and production process, which is applied in the printing process, printing of special varieties of printed matter, packaging paper, etc. It can solve the problems of non-environmental protection, general production process, and single production process, so as to increase the difficulty of imitation, The anti-counterfeiting level is improved and the production process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Preparation of release layer

[0024] Coating a release agent with a dry and wet weight of 1.3±0.5g / ㎡ on the polyester (BOPET) film, the release agent is dried at a temperature of 120°C to form a release layer on the film; the coating and drying The vehicle speed is 120±10m / mm.

[0025] b. Laser molding

[0026] According to the characteristics of different products, make a personalized laser master, so that the laser information can be transferred to the surface release layer through the master. Make laser information with text, graphics or a combination thereof on nickel molded rollers. The surface effect is bright or matte, which makes the laser information diffract strongly, and then transfers the laser information to the above-mentioned release layer through the molded roller with a temperature of 175°C .

[0027] c, silicone oil pattern printing

[0028] Laser engrave the noticeable text or the combination of text and pattern on the resin roller. The patter...

Embodiment 2

[0036] a. Preparation of release layer

[0037] Coating a release agent with a dry and wet weight of 1.3±0.5g / ㎡ on the polypropylene (BOPP) film, the release agent is dried at a temperature of 130°C to form a release layer on the film; the coating and drying The vehicle speed is 120±10m / mm.

[0038] b. Laser molding

[0039] According to the characteristics of different products, make a personalized laser master, so that the laser information can be transferred to the surface release layer through the master. Make laser information with text, graphics or a combination on the nickel molded roller. The surface effect is bright or matte, so that the laser light information is strongly diffracted, and then the laser information is transferred to the above-mentioned release layer through the molded roller with a temperature of 185°C .

[0040] c, silicone oil pattern printing

[0041] Laser engrave the noticeable text or the combination of text and pattern on the resin roller. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com