Construction Method of Prefabricated Rising Column and Raising Beam Composite Frame Structure

A frame structure and construction method technology, applied to the processing of building components, building structures, and building materials, can solve the problems of slow construction progress and long construction period, so as to improve construction speed, shorten construction period, and increase production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

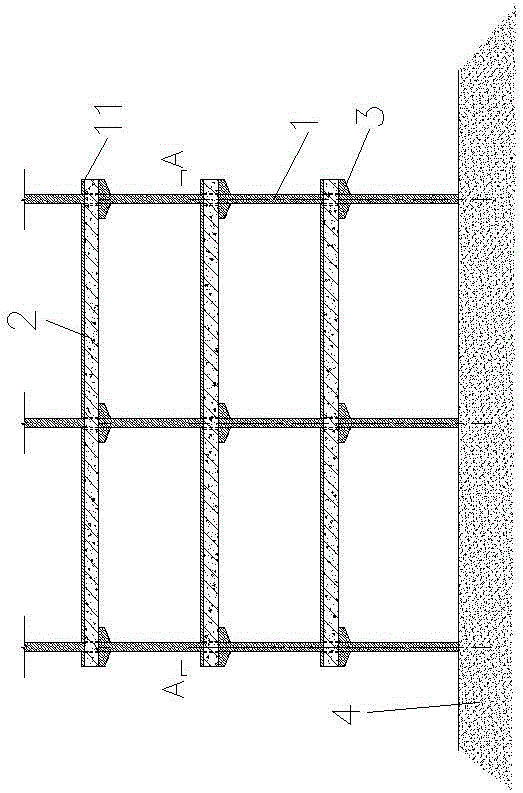

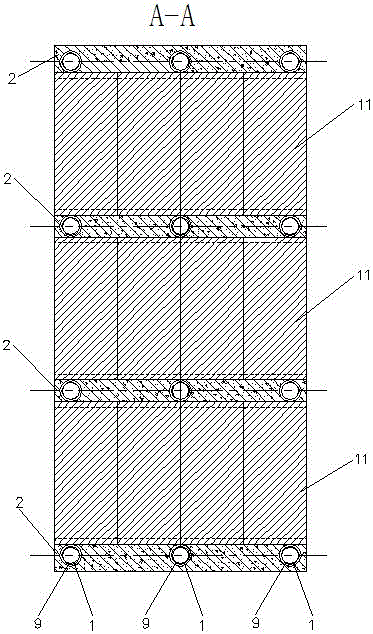

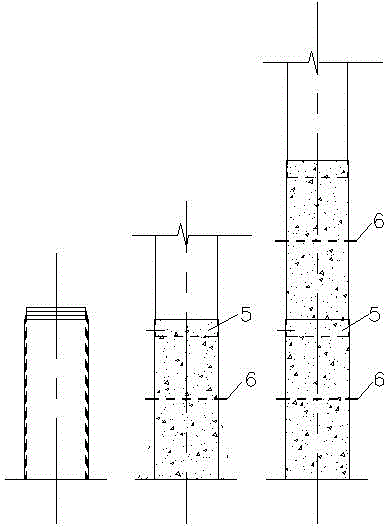

[0039] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0040] A construction method for a prefabricated rising column and rising beam composite frame structure, which comprises the following steps:

[0041] (1) Excavate the foundation pit, pour the reinforced concrete foundation 10, and an independent foundation under the column can be used;

[0042] (2) Flatten the floor 4, place the prefabricated concrete beams 2 of each layer, the prefabricated concrete beams 2 of each layer should be separated by backing plates, and should be positioned and placed accurately to ensure the insertion of the steel pipe sleeve column 1;

[0043] (3) Insert the steel pipe sleeve 1, and make a solid connection between the steel pipe sleeve 1 and the foundation 10;

[0044] (4) The crane is in place, and the inner steel pipe sleeve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com