Novel circulating water pump station system

A circulating water pump and water pump technology, which is applied in the direction of air conditioning system, cooling fluid circulation device, heating method, etc., can solve the problems of large difference in service life of equipment, low equipment utilization rate, low reliability, etc., and achieve increased circulation and stability Improve and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

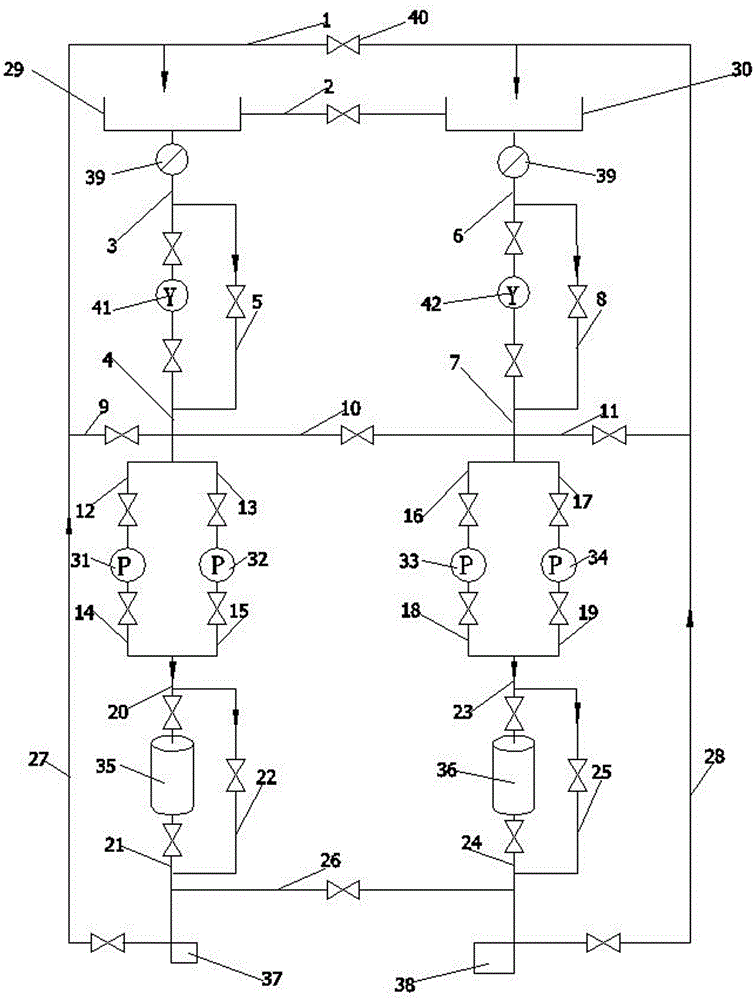

[0015] Such as figure 2 As shown, a novel circulating water pumping station system of the present invention includes an equipment circulation loop and an air conditioning circulation loop, and the equipment circulation loop includes a left cooling tower 29, a left Y-shaped filter 41, a left water pump group, and a left self-cleaning filter 35 and cooling equipment 37, cooling equipment 37 is the chiller of equipment such as rolling mill, degreasing machine or surface treatment machine, described left cooling tower 29 communicates with left Y-type filter 41 through the first left connecting pipe 3, the first The left connecting pipe 3 is provided with a coarse filter 39, the left Y-shaped filter 41 communicates with the left water pump group through the second left connecting pipe 4, and the left water pump group and the left self-cleaning filter 35 are connected through the third left The pipe 20 communicates, the left self-cleaning filter 35 communicates with the cooling equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com