Gas detection device

A gas detection and gas technology, applied in the field of gas leakage detection, can solve the problems of narrow absorption band, poor effect, inconvenient production, etc., and achieve the effects of reducing equipment production cost, improving observation effect, and being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

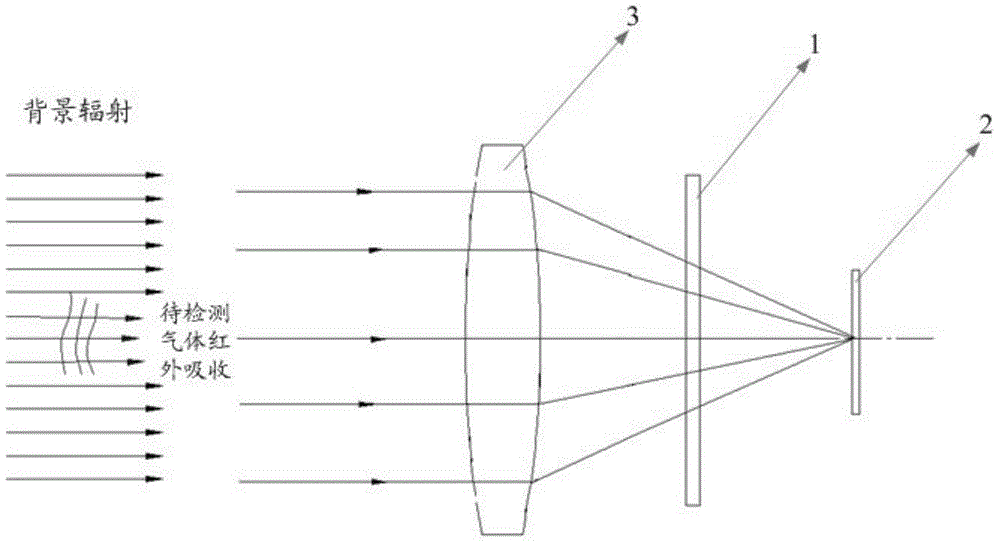

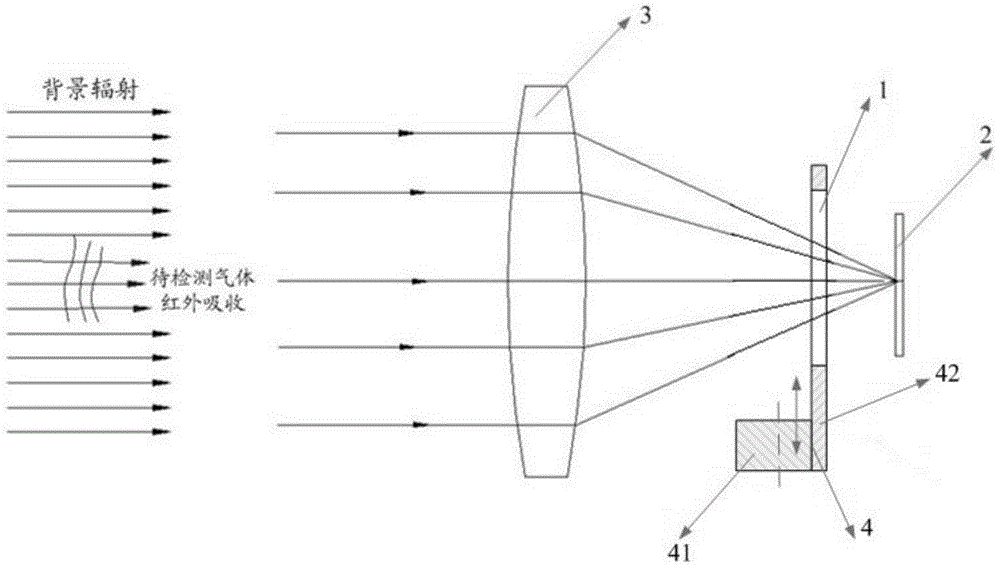

[0024] figure 1 A schematic structural diagram of a gas detection device according to an embodiment of the present invention is shown, wherein the gas detection device includes: an optical filter 1, wherein the transmission band of the optical filter 1 includes the corresponding infrared absorption peak of the gas to be detected wavelength; the uncooled infrared detector 2 is used to acquire and output the infrared imaging information passed through the filter; the infrared lens 3 is used to converge the infrared rays of the object to the uncooled infrared detector 2 .

[0025] Here, the gas to be detected refers to any gas with infrared absorption characteristics, such as sulfur hexafluoride (SF6), ethylene, acetic acid, chlorine dioxide, etc., which have different infrared absorption peak wavelengths, such as the infrared absorption of SF6 The peak wavelen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fwhm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com