Method and system applied to in-situ crack detection of wind generator blade

A technology for wind turbine and crack detection, which is applied in the direction of optical testing for flaws/defects, etc. It can solve the problems of high operation and maintenance costs, the detection process is easily disturbed by background noise, and the economic benefits are greatly affected, and achieves fast calculation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

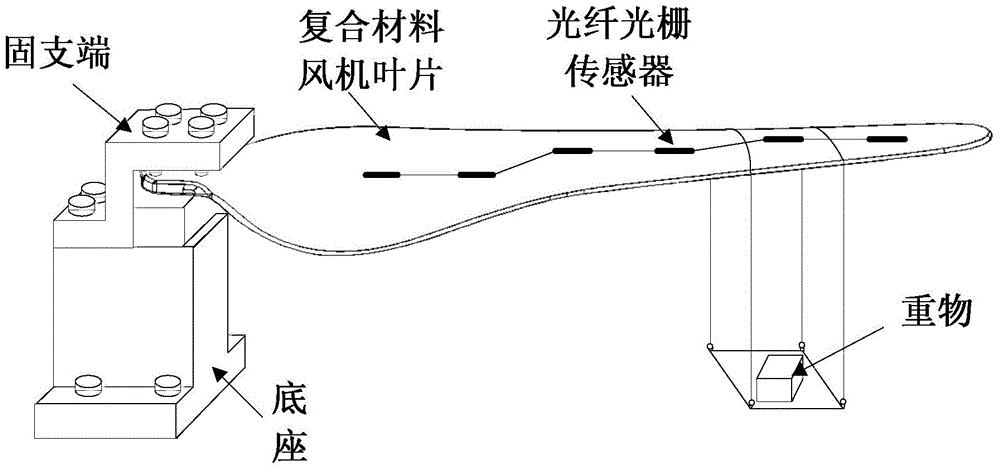

[0039] In this exemplary example, bolts are used to fix the wind turbine blades on the base, and the boundary condition of the wind turbine blades is fixed at one end. Fiber Bragg gratings are selected according to the shape, size, and detection accuracy requirements of the blades. The number of sensors is 12, and these sensors are pasted on the windward side of the wind turbine blades. The wavelengths of the 12 sensor gratings can be different, such as figure 1 shown. Use pre-made steel plates and sandbags to apply static loads to wind turbine blades, and use MOI's optical fiber grating demodulator SM130 to demodulate and record wind turbine blades under different static loads between 1200N and 6200N (increments of 500N) The static response of , where the sampling frequency is set to 1000Hz.

[0040] Such as figure 2 As shown, the static responses of wind turbine blades under 10 different static loads obtained by sampling are selected. These 10 static loads are provided by...

Embodiment 2

[0054] Such as figure 1 The shown wind turbine blade with a length of 13m is pasted with a fiber grating sensor containing 12 gratings on the windward side, and there is a crack near the sixth grating. Static excitation is applied at the position of 6.6m, and the static response of the wind turbine blade under different static loads between 1200N and 6200N (increment of 500N) is obtained.

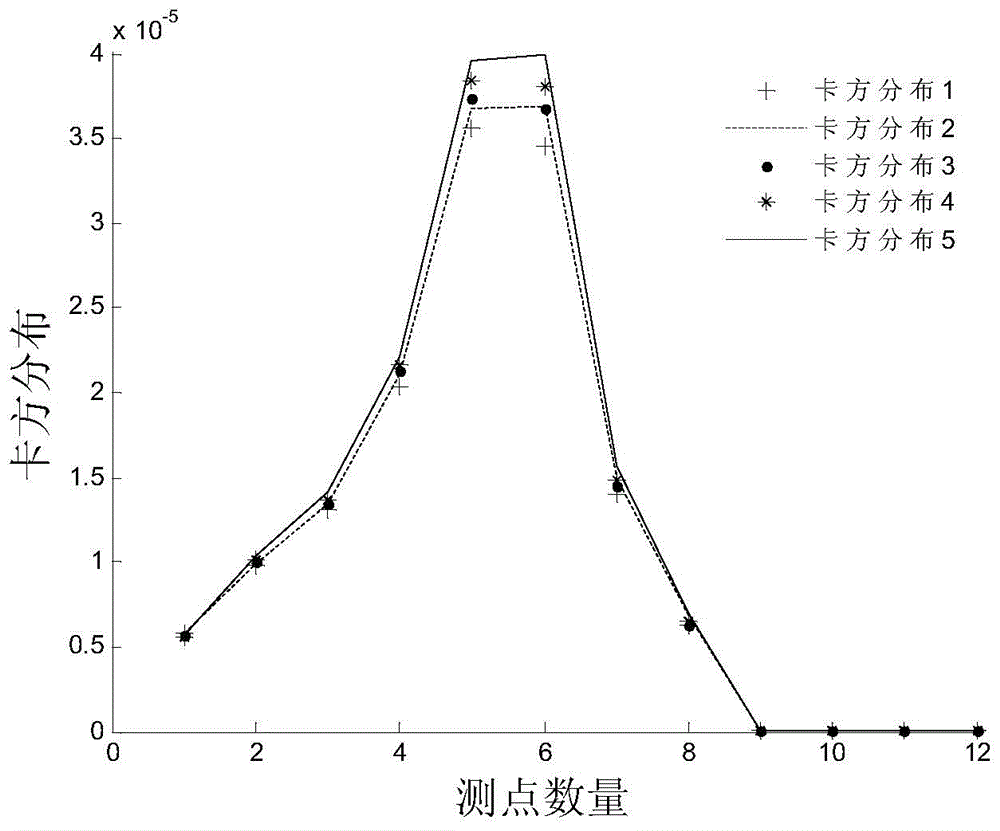

[0055] Select 10 groups of static responses of wind turbine blades with different static loads and the gap between static loads is 1000N, respectively calculate the chi-square distribution curve between two non-repetitive static responses, denoted as CSD 1 (x),...,CSD 5 (x), such as figure 2 shown by figure 2 It can be seen that the value difference of the chi-square distribution curve at the fifth or sixth grating position is very small, so it is considered that the maximum value of the chi-square distribution curve is at the fifth or sixth grating position, that is, the blade is at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com