Microwave ultraviolet lamp based on electron cyclotron resonance principle

A technology of electron cyclotron resonance and ultraviolet lamps, which is applied to the components and circuits of discharge lamps and gas discharge lamps. It can solve the problems of low luminous efficiency, poor UV curing effect, long start-up time, etc. Good curing effect and shortened start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

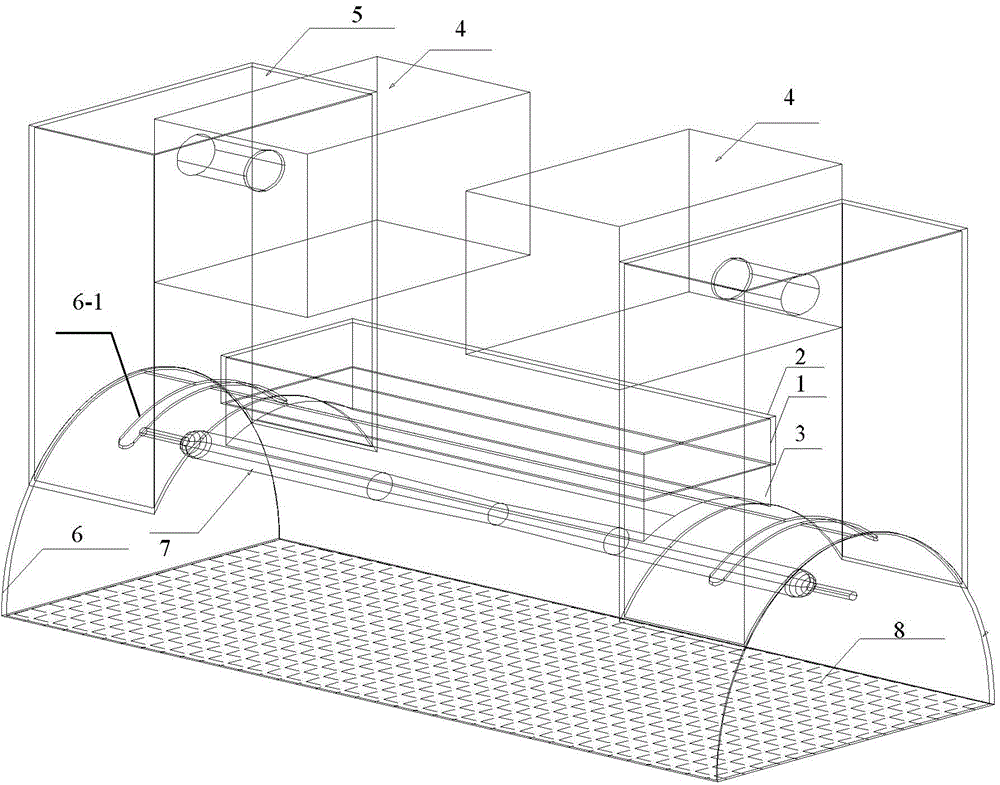

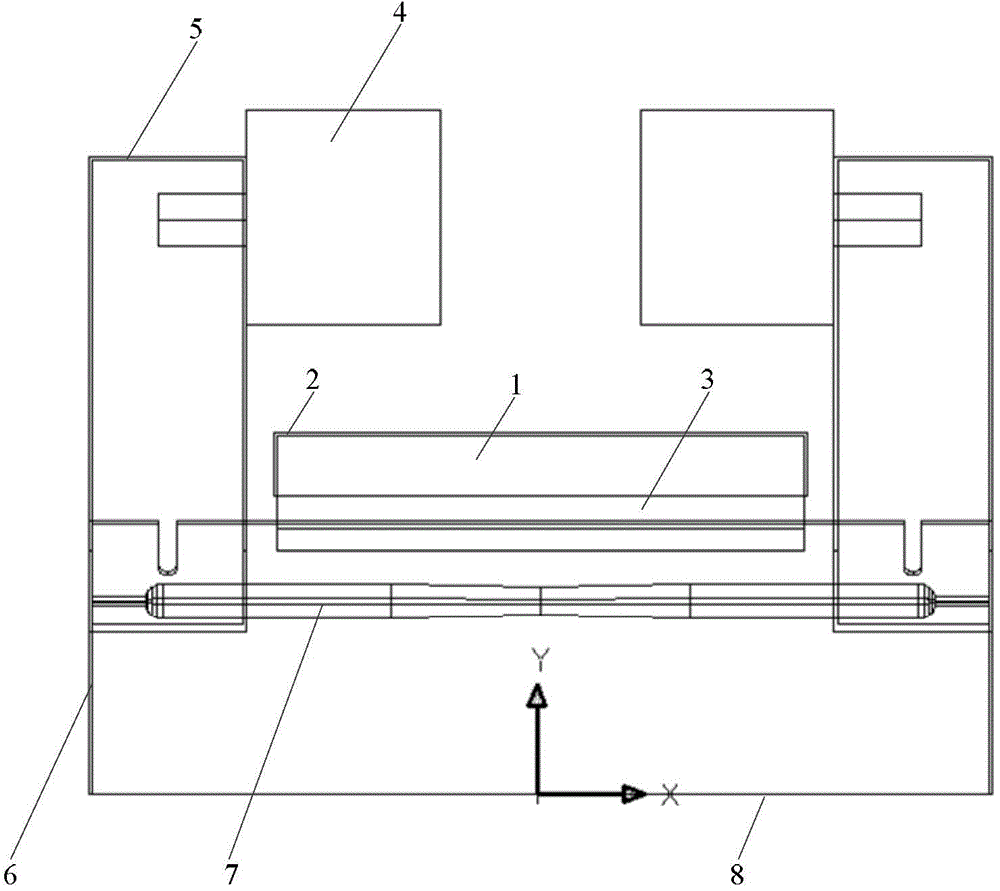

[0020] Specific implementation mode 1, refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 Describe this embodiment in detail, a kind of microwave ultraviolet lamp based on electron cyclotron resonance principle described in this embodiment, it comprises magnetron 4, magnetron excitation cavity 5 and lamp tube 7, and magnetron 4 is used for its The emitted microwave is injected into the magnetron excitation cavity 5; it also includes a permanent magnet 1, a permanent magnet protective shell 2, an asbestos board 3, a reflector 6 and a metal shielding net 8;

[0021] The metal shielding net 8 is fixed on the bottom of the reflector 6, and the metal shielding net 8 and the reflector 6 form a microwave resonant cavity; the lamp tube 7 is fixed in the microwave resonant cavity, and the central axis of the lamp tube 7 and the transverse axis of the reflector are at the same plane, and the lamp tube 7 is placed along the first focal axis of the reflect...

specific Embodiment approach 2

[0031] Specific embodiment 2. This specific embodiment is a further description of a microwave ultraviolet lamp based on the principle of electron cyclotron resonance described in specific embodiment 1. In this embodiment, the permanent magnet 1 is made of NdFeB permanent magnet. magnet.

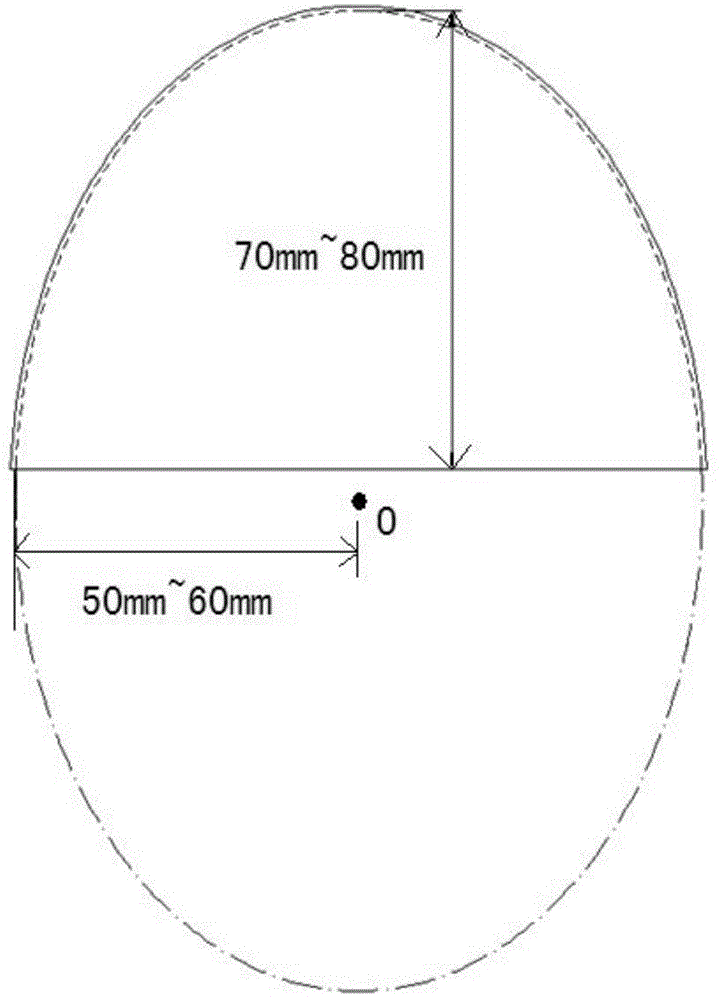

[0032] The permanent magnet 1 is N35 NdFeB permanent magnet material, its remanence is 1.2T (Tesla), and the remanence direction is along the Y-axis direction, such as Figure 5 shown. The bottom surface of the permanent magnet 1 is 30mm away from the focal axis of the reflector 6, and the size of the permanent magnet 1 is as follows: Figure 4 shown.

specific Embodiment approach 3

[0033] Specific Embodiment Three. This embodiment is an example.

[0034] The semi-major axis of the reflector 6 is 71.8mm, the semi-minor axis is 53.9mm, and the thickness is 0.8mm; the length of the feeding port on the upper surface of the reflector 6 is 60mm, and the width is 5mm.

[0035] The constant magnetic field produced by the permanent magnet 1 at the central axis of the lamp tube 7 is as Image 6 shown. From Image 6 It can be seen from the figure that on the 80mm length of the middle part of the lamp tube 7, the constant magnetic field strength is between 850Gs-900Gs, which is close to 875Gs, which meets the technical requirements proposed by the present invention and can well solve the problem of lamp tubes existing in the prior art. The middle part has problems such as long start-up time and low luminous efficiency.

[0036] The principle of electron cyclotron resonance means that when the electron cyclotron frequency is equal to the microwave frequency used, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com