Phase change module and electronic device mounted with same

A phase change and heat sink technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of unclear structure, no mention, no consideration of thermal conductivity, etc., to achieve low cost, high efficiency and reliability cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (basic structure)

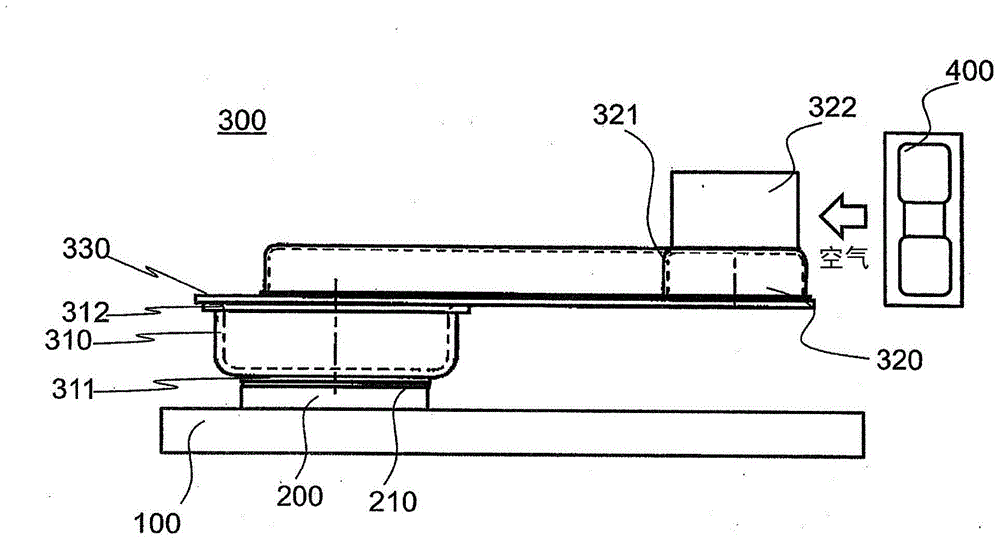

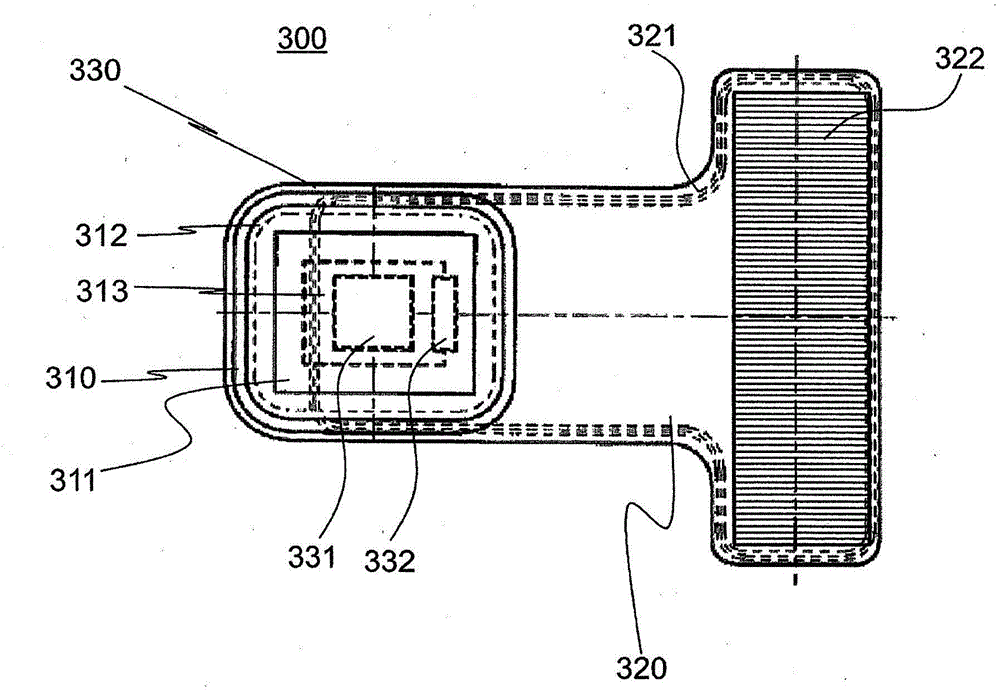

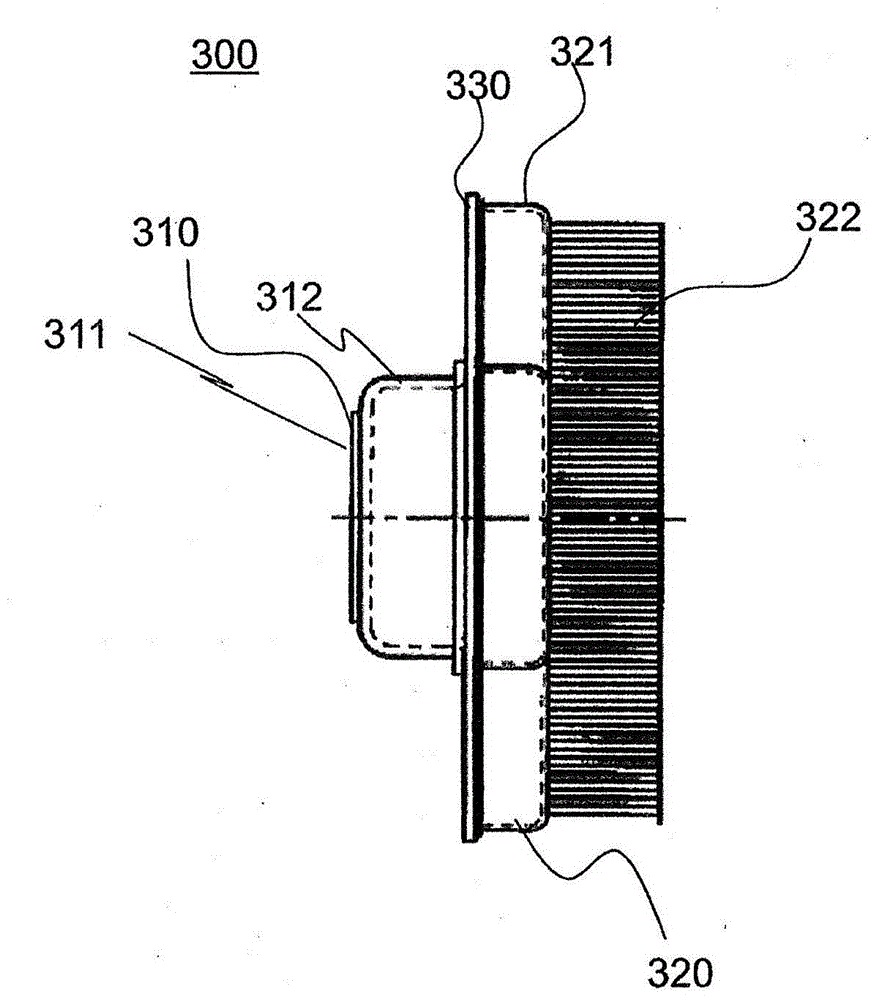

[0051] figure 1The overall structure viewed from the side around the phase change module 300 using thermosyphon is shown. In the drawings, reference numeral 100 denotes a circuit board on which a semiconductor device 200 as a heat source such as a CPU is mounted. Furthermore, a heat receiving sheath 310 constituting a part of the phase change module 300 utilizing thermosiphon of the present invention is mounted on the surface of the semiconductor device 200 . The heat receiving sheath 310 is composed of a boiling heat conducting surface 311 and a sheath shell 312 . The boiling heat transfer surface 311 is fixed to the sheath shell 312 by brazing or the like. More specifically, a so-called thermal grease 210 is applied on the surface of the semiconductor device 200 to ensure good thermal bonding with the boiling heat transfer surface 311, and the bottom surface of the above boiling heat transfer surface 311 is brought into contact with the surface a...

Embodiment 2

[0060] (with a core on the connecting plate)

[0061] Figure 4 A side view of a phase change module 300 for increasing heat tolerance is shown as another embodiment. A core member 333 is provided on the connecting plate 330 . The core member 333 is constituted by a twisted wire of thin metal wires, a netted metal net, or the like. The length of the core member 333 is the length from the position of the fin 322 of the condenser 320 to a liquid return hole (not shown). By providing the core member 333, the high-speed flow of the refrigerant vapor will not hinder the flow of the liquid return, but the refrigerant liquid can be guided to the liquid return hole. Thereby, the coolant can be sufficiently supplied to the boiling heat transfer surface 311, and the allowable amount of heat received from the semiconductor device can be increased.

Embodiment 3

[0063] (with threaded holes on the connecting plate)

[0064] Figure 5 A side view of a phase change module 300 in consideration of mounting on a semiconductor device is shown as another embodiment. The connecting plate 330 is provided with a screw mounting hole 340 for mounting to a semiconductor device. The screw mounting holes 340 are provided at positions corresponding to the screw holes provided in the circuit board. Accordingly, the phase change module 300 can be stably mounted on the semiconductor device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com