Preparation method of cathode active substance for lead carbon battery

A negative electrode active material, lead-carbon battery technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of inability to integrate the characteristics of super capacitors, reduce the strength of the plate, reduce the cycle life and other problems, and improve the high current charge and discharge capacity and cycle life. performance, inhibition of sulfation, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

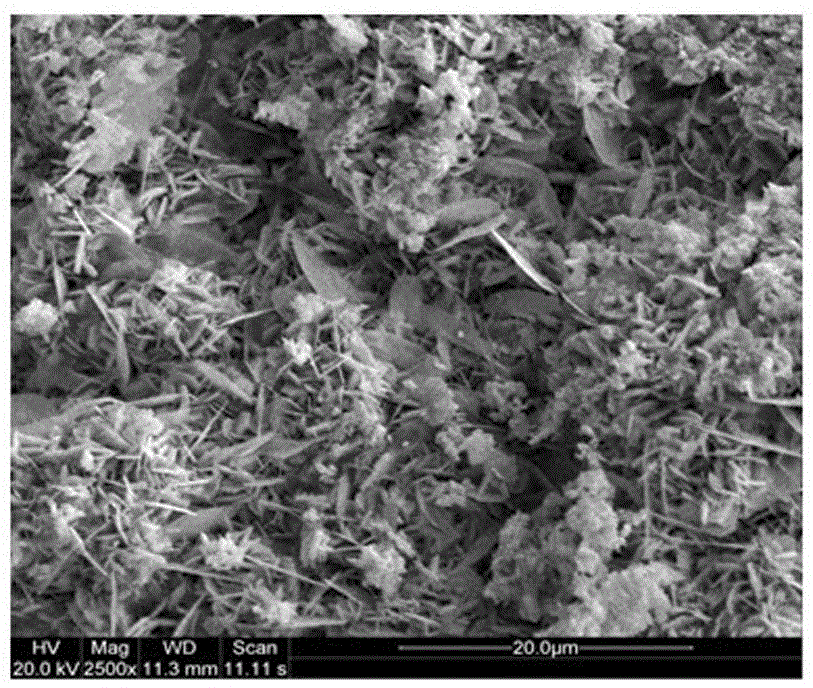

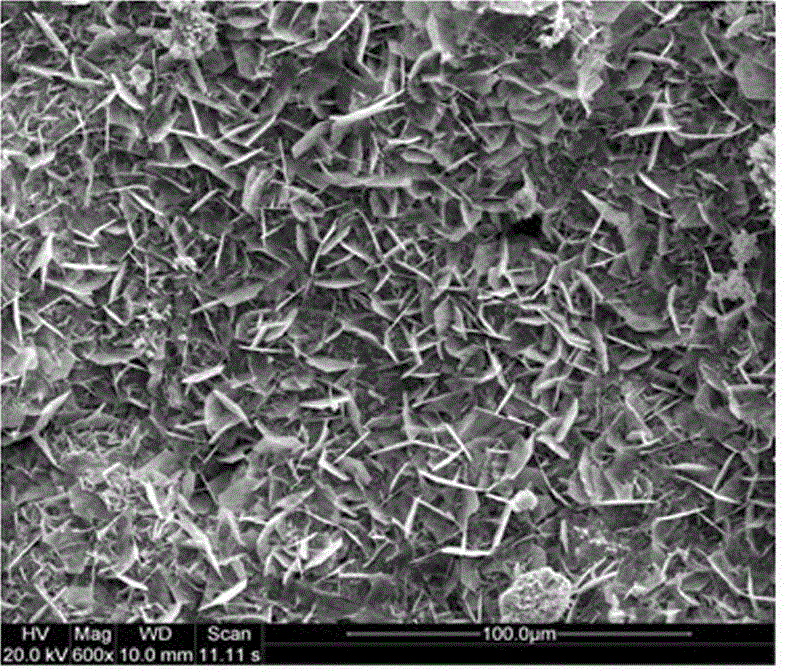

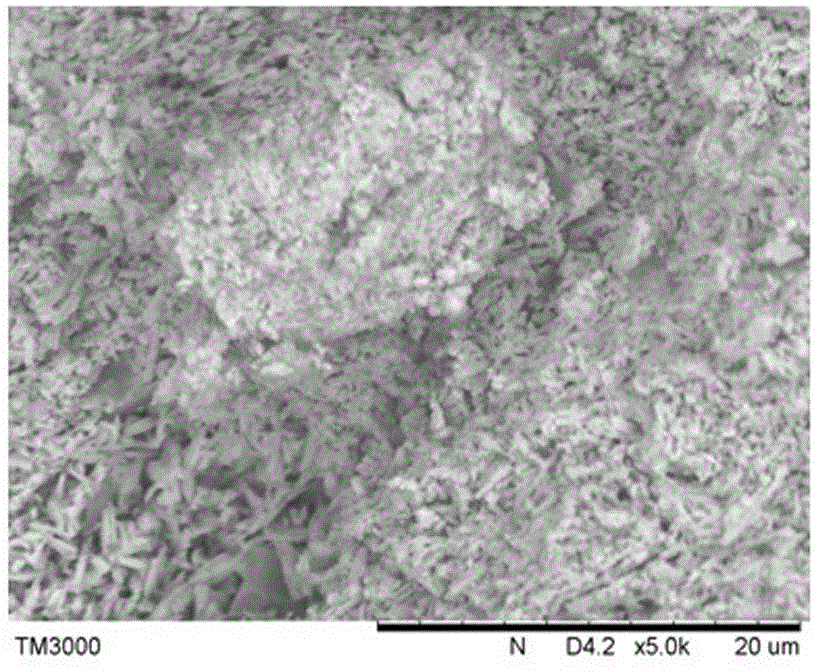

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described through the specific operation of the examples and the test and comparison of batteries produced by the present invention and the existing method respectively.

[0019]

[0020] Note: % in the table are all mass percentages; the density of sulfuric acid used is 1.35g / cm 3 ; The dry mixing, wet mixing, and acid mixing materials are the same as those described above in the description, and the acid mixing time includes the acid adding time and the continuation stirring time after adding the acid.

[0021] The technology not involved in the specific operation of the embodiment is the same as the existing process; the temperature during the preparation of the lead paste does not exceed 72°C, and the temperature of the paste is controlled at 50-55°C.

[0022] Manually smear the lead paste produced by the above-mentioned blending process and the lead paste produced by the current process, and mark the two ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com