Differential electric motor

A technology of electric motor and differential speed, which is applied in the field of motors, can solve problems such as unsmooth turning, tire wear, and space occupation of the car body, and achieve the effects of easy assembly, reduced manufacturing costs, and lightened car body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

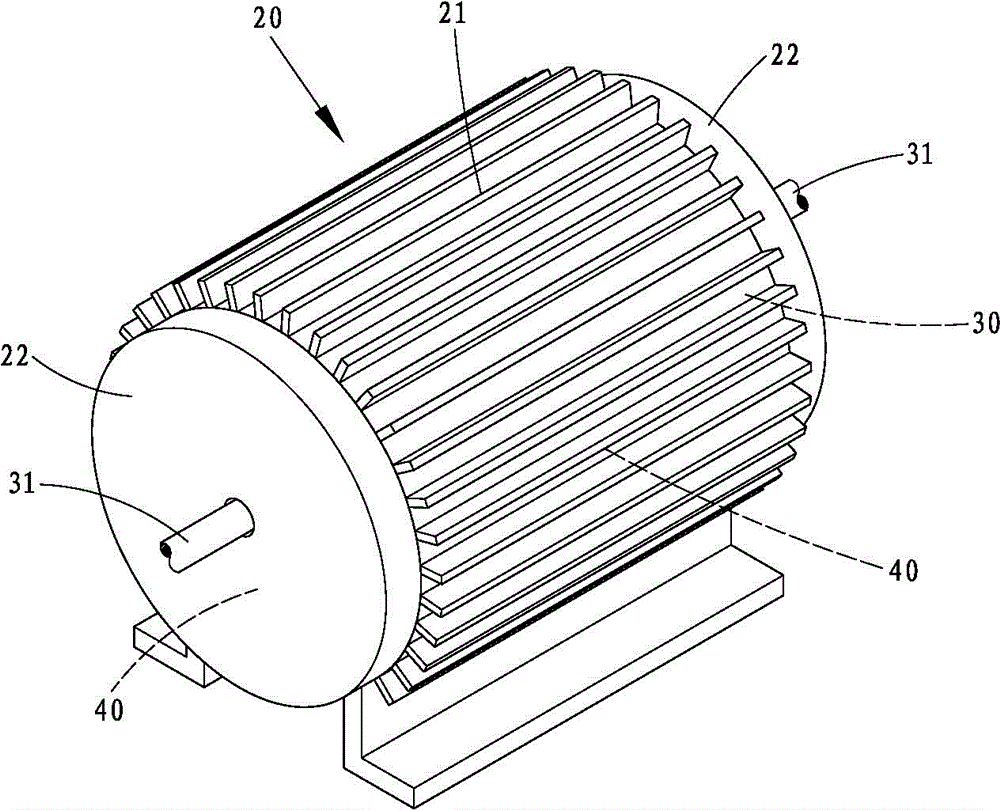

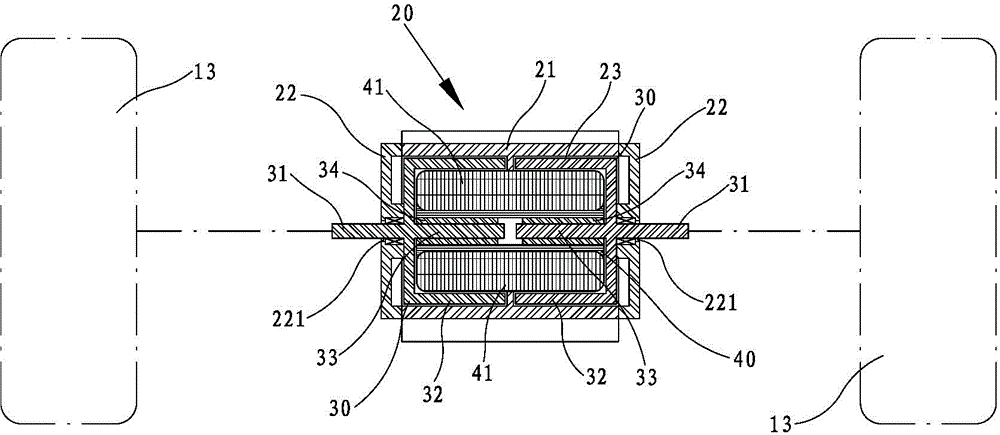

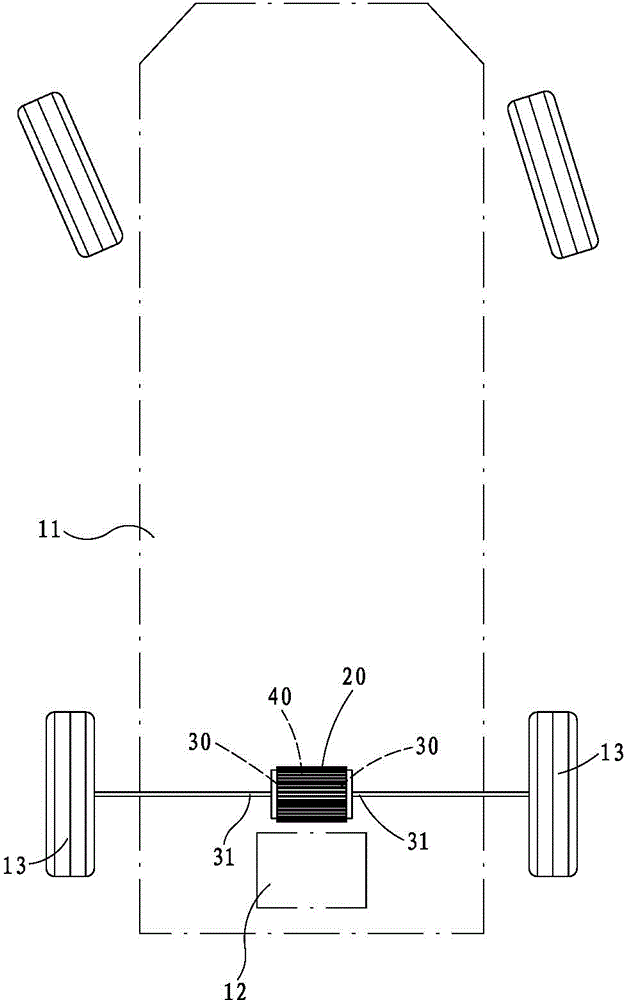

[0029] Such as figure 1 It is a three-dimensional view of the appearance of the differential motor of the present invention, figure 2 Shown in the cross-sectional view of the structure of the differential motor in the first embodiment of the present invention, the differential motor of the present invention basically has a motor stator 40 fixed at the middle section of a body 20 for connecting to an external power supply and generating an electromagnetic field. On both sides of the main body 20 , a motor rotor 30 for driving and rotating by the electromagnetic field of the motor stator 40 is respectively arranged on the shaft.

[0030] exist figure 1 and figure 2 In the shown embodiment, the body 20 can be assembled from a hollow middle section 21 and two side covers 22 relatively locked at the openings on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com