Intelligent high-voltage inverter cooling control system

A high-voltage inverter, cooling control technology, applied in cooling/ventilation/heating renovation, power electronics modification, output power conversion device, etc. Cooling and cooling requirements, prolonging service life, and ensuring the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

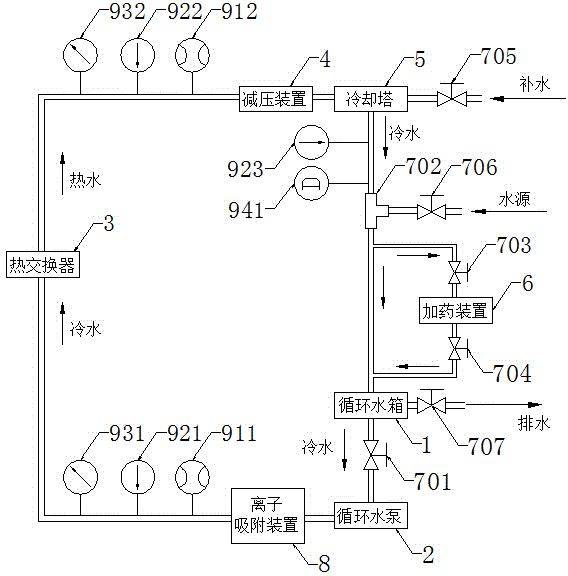

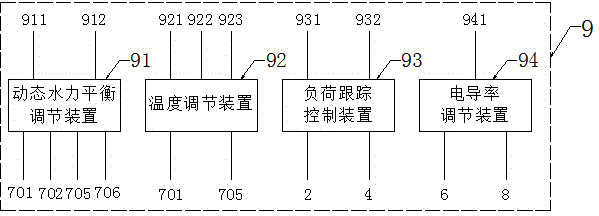

[0030] A high-voltage inverter intelligent cooling control system in this embodiment, such as figure 1 As shown, the circulating water cooling system includes a monitoring system 9 and a circulating water tank 1, a circulating water pump 2, a heat exchanger 3, a decompression device 4, and a cooling tower 5 connected in sequence; the circulating water cooling system also includes a valve 7; The monitoring system 9 includes an external detection instrument, a control system and a valve; the external detection instrument is arranged at both ends of the heat exchanger 3 and the water outlet of the cooling tower 5; the control system includes a dynamic hydraulic balance adjustment device 91 , a temperature regulating device 92 , a load following control device 93 , and a conductivity regulating device 94 . A three-way valve 702 is also arranged between the cooling tower 5 and the circulating water tank 1, and the three-way valve 702 is connected with the circulating water tank 1 i...

Embodiment 2

[0035] In this embodiment, after the dynamic hydraulic balance adjustment device 91 in the monitoring device collects and analyzes the parameters of the flowmeter, it is found that the flow rate at the inlet of the heat exchanger is smaller than the flow rate at the outlet, and the valve A701 is increased. If the water level in the circulating water tank is insufficient, it needs to be opened. Valve F706 allows the water source to replenish. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

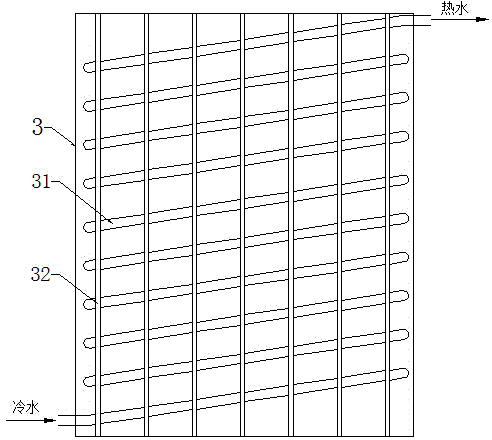

[0037] In this embodiment, an air cooling system is added on the basis of Embodiment 1. The fan blows cold air at 25°C from the air cooling device into the high-voltage inverter. The cold air absorbs heat and becomes hot air. The temperature in the high-voltage inverter cabinet is not higher than 55 ℃, on the one hand, the hot air increases the temperature of the cooling fins 32, and the cooling water pipe 31 passing through the cooling fins 32 absorbs the heat of the hot air and turns it into hot water. After passing through the cooling tower 5, the cooling water drops below 30 °C, and then stands still to about 25°C; on the other hand, the hot air enters the air duct through the fan on the top of the cabinet, and the axial flow fan 12 blows the hot air to the cooling tower 5, the cold water is from top to bottom, and the hot air is from bottom to top to realize heat exchange. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com