Ultrafiltration membrane module and method for treating high-turbidity water by using same

A technology of ultrafiltration membranes and components, applied in ultrafiltration, osmosis/dialysis water/sewage treatment, etc., to achieve the effects of high effluent safety, non-fouling blockage, and improved anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

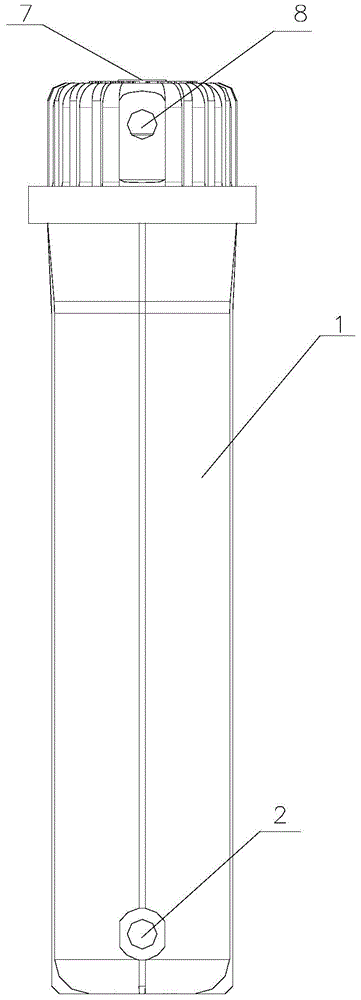

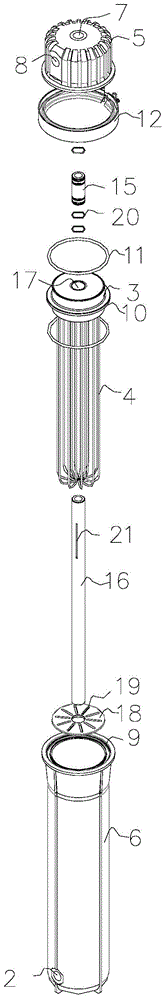

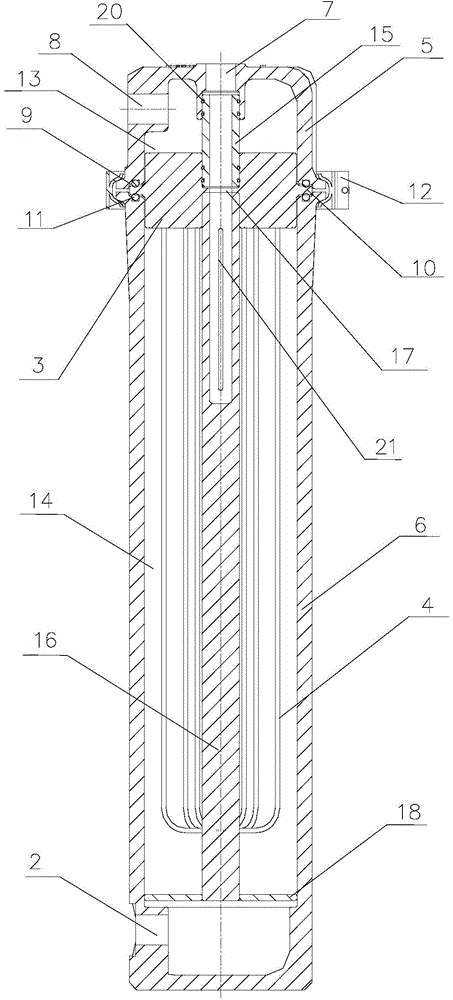

[0029] Such as figure 1 , 2 As shown, an ultrafiltration membrane assembly includes a shell 1 and a filter element made of PP material. Among them, the shell 1 is cylindrical, and the shell 1 is composed of an upper end cover 5 and a lower body 6, the top of the end cover 5 is provided with a concentrated water outlet 7, and the side of the end cover 5 is provided with a water production port 8; the body 6 A water inlet 2 is provided on the bottom side wall.

[0030] The filter element is composed of a membrane cover 3 and a membrane filament 4 . The membrane filament 4 is a polyvinylidene fluoride (PVDF) hollow fiber membrane, the diameter of the membrane filament 4 is 1.25-1.35 mm, and the diameter of the membrane hole is 0.03-0.1 μm; the membrane filament 4 is bent to form a "U" shape, and the membrane is sealed 3. It consists of a ring-shaped PP shell and a glue-sealed injection core. The two ends of each membrane wire are sealed in the ring-shaped shell with epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com