Large-scale laser efficient cutting machine

A large-format, cutting machine technology, used in laser welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of unsuitable transportation of various texture materials, low efficiency of laser cutting machines, and manual typesetting, etc. The effect of utilization rate, high production capacity and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

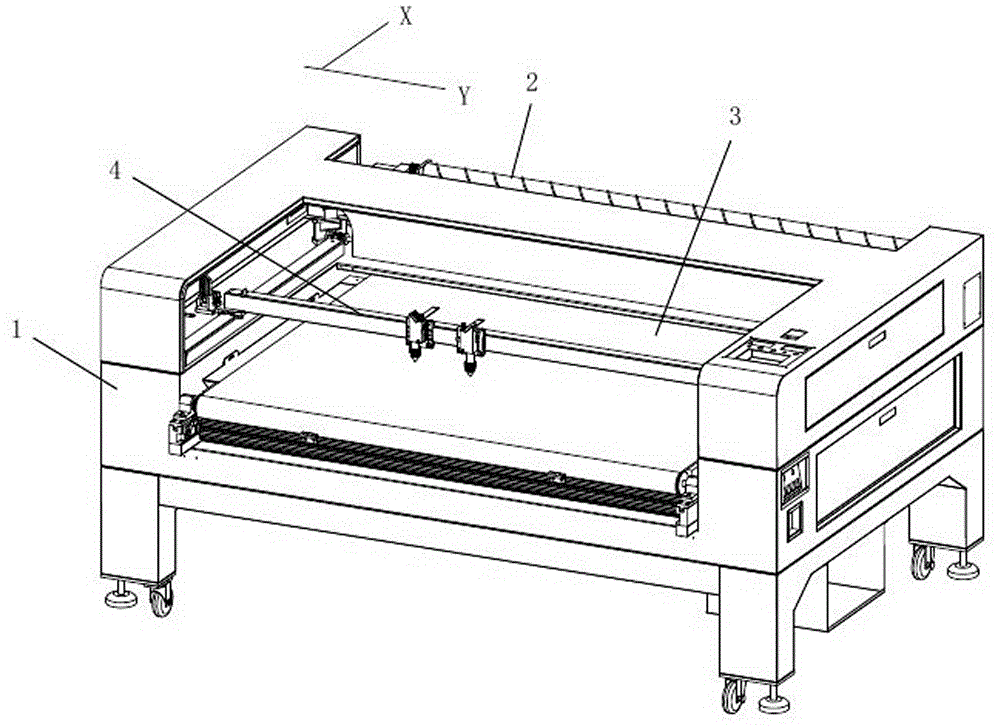

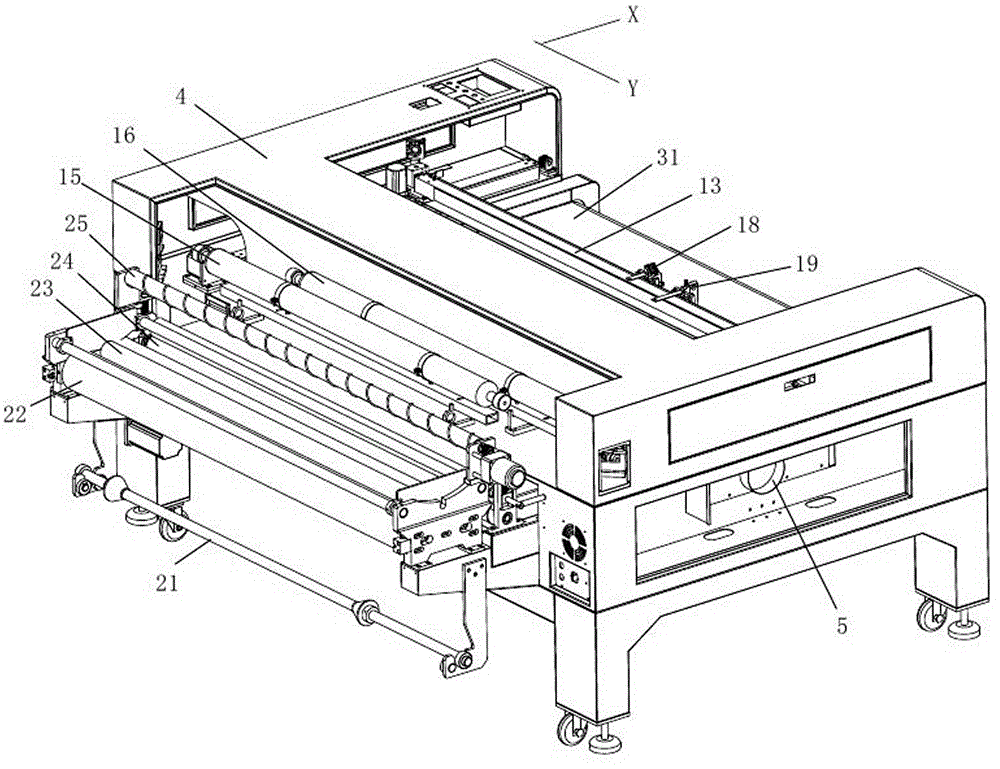

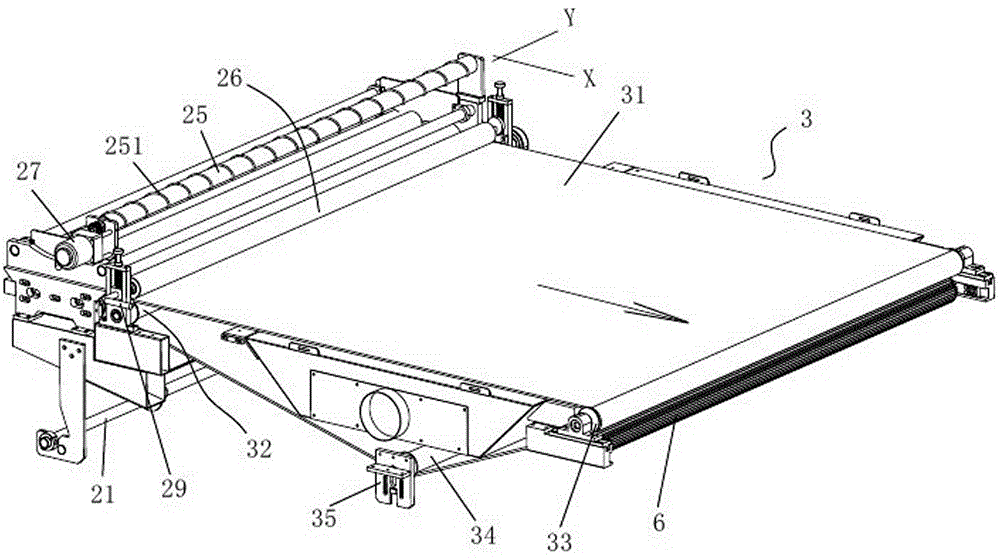

[0041] Such as Figures 1 to 8 As shown, the large-format laser high-efficiency cutting machine includes the optical path assembly 1, the conveying device and the control system for conveying the materials to be processed;

[0042] The optical path assembly 1 includes two laser heads, namely the first laser head 19 and the first laser head 191, the X-guiding rails are set, that is, the first X-guiding rail 11 and the first X-guiding rail 12, and the Y-guiding rail 13 is also set. , where the X guide rail is consistent with the direction of conveying the material to be processed, the two laser heads can move in the X direction and the Y direction, and cut separately along their respective paths to complete the entire cutting together.

[0043] The conveying device includes a roller assembly 2 and a screen conveyor belt device 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com