Plasma arc ultrasonic welding process and device

A plasma arc and ultrasonic welding technology, which is applied to welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of different welding equipment structures and no ultrasonic waves, and achieve improved welding quality, reduced welding deformation, and dense and uniform molten metal structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

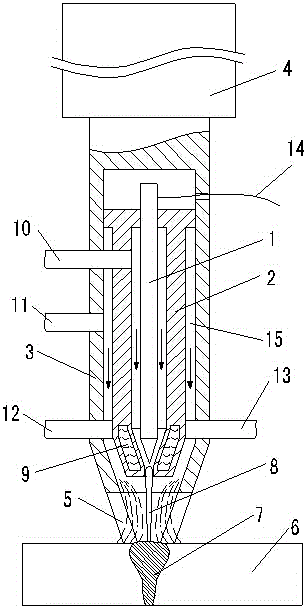

[0016] Plasma arc ultrasonic welding device of the present invention such as figure 1 As shown, it mainly includes a transducer 4 and a horn 3, the transducer 4 is fixedly connected to one end of the horn 3, and a cavity for accommodating the nozzle is provided at the other end of the horn 3, in the cavity A welding nozzle 2 is arranged in the middle, and the gap between the welding nozzle 2 and the cavity forms a protective gas chamber 15. The center of the welding nozzle 2 is provided with an electrode 1, and an annular cooling water chamber 9 is arranged inside the welding nozzle 2. The cooling water chamber 9 communicates with the water inlet pipe 12 and the water outlet pipe 13 on the welding nozzle 2 to form circulating cooling water to cool the welding nozzle 2 . The welding nozzle 2 is also provided with an ion gas intake pipe 10 , and the ion gas intake pipe 10 extends out of the horn 3 . The horn 3 is provided with a shielding gas intake pipe 11 communicating with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com