Preparation method of multi-response graphene/graphite oxide film

A multi-response, graphene technology, applied in the field of preparation of multi-response materials, can solve the problems of limited performance and application, complex polymer orientation process, slow recovery rate, etc., and achieve the effect of good mechanical properties and electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

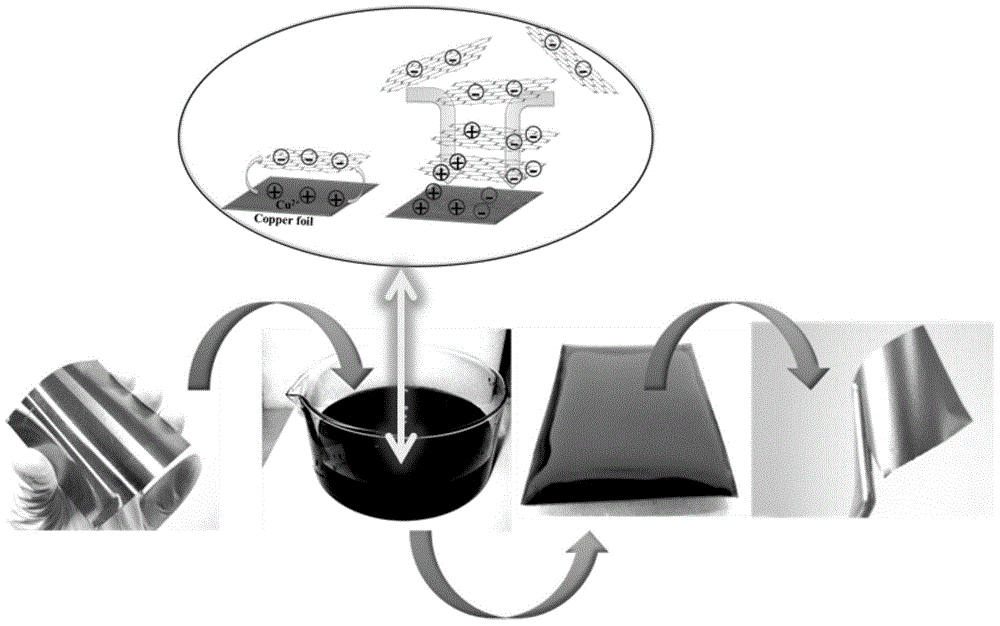

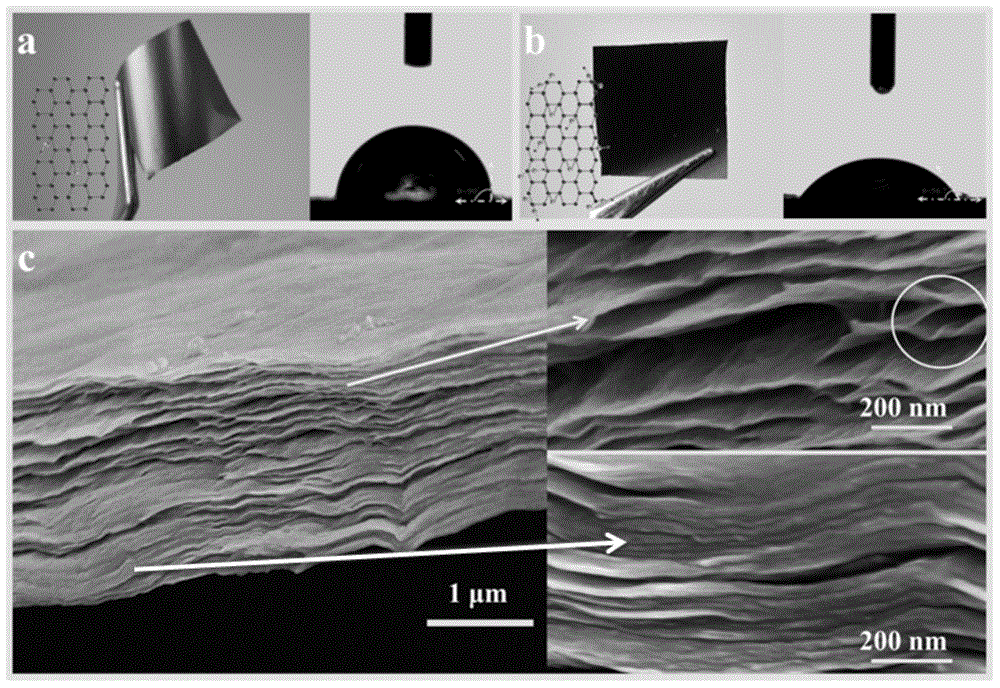

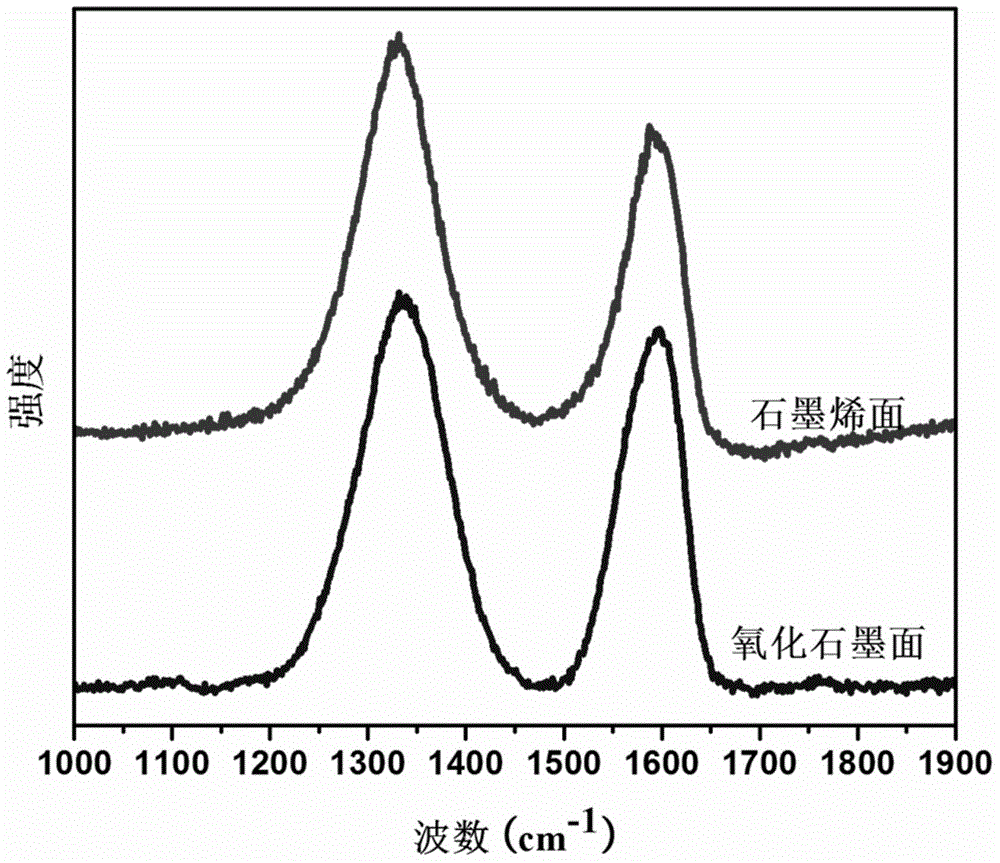

[0035] Disperse the highly exfoliated graphite oxide in deionized water at a concentration of 1 mg / ml, add sulfuric acid dropwise to adjust the pH to 2, and then ultrasonically disperse to obtain a graphite oxide aqueous solution with good stability. Clean the desired copper plate ultrasonically with an organic solvent (ethanol or acetone) and then dry it and place it at the bottom of the glass vessel (10 cm from the liquid surface) filled with the previously configured graphite oxide aqueous solution. Put the glassware on a horizontal platform for 1 day and keep the temperature at 20°C. Take out the bottom copper plate. At this time, a layer of graphene / graphite oxide hydrogel is deposited on the surface of the copper plate. Put the copper plate in a drying oven at 25°C It was taken out after drying for 6 hours, and then the film was peeled off from the copper plate. figure 2 It is the field emission scanning electron microscope figure of the graphene / graphite oxide film cro...

Embodiment 2

[0039] Disperse the highly exfoliated graphite oxide in deionized water at a concentration of 5 mg / ml, add sulfuric acid dropwise to adjust the pH to 4, and then ultrasonically disperse to obtain a graphite oxide aqueous solution with good stability. Clean the desired copper plate ultrasonically with an organic solvent (ethanol or acetone) and then dry it and place it at the bottom of the glass vessel (10 cm from the liquid surface) filled with the previously configured graphite oxide aqueous solution. Put the glassware on a horizontal platform for 1 day and keep the temperature at 30°C. Take out the bottom copper plate. At this time, a layer of graphene / graphite oxide hydrogel is deposited on the surface of the copper plate. Put the copper plate in a drying oven at 50°C After drying for 2 hours, it was taken out, and then the film was peeled off from the copper plate. The removed film is in a flat state, and it is placed on a water vapor permeable non-woven fabric (hot water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com