Preparation method of premium-grade stannous chloride from low-tin waste residues

A technology of stannous chloride and tin waste residue, applied in the direction of stannous chloride and tin halide, which can solve the problems of low recovery rate and achieve low cost, simple process and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

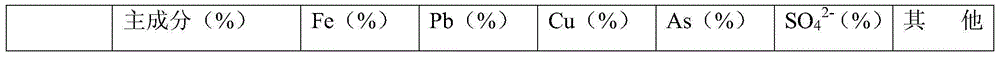

Embodiment 1

[0024] A kind of method utilizing low-tin waste slag to prepare excellent grade tin protochloride, comprises the following steps:

[0025] (1) Prepare reaction solution: take 200kg of low-tin waste residue and put it into 2m 3 Add 500L of water and mix uniformly, then add 300L of concentrated hydrochloric acid with a mass percentage of 37.5% to adjust the acidity to 3g / l; the low-tin waste slag is the waste slag produced in the process of producing tin processed products;

[0026] (2) Chlorine: feed chlorine gas into the reaction solution, and wait for the Sn in the reaction solution to 4+ Stop chlorine flow when the content reaches 450g / l;

[0027] (3) Settling: the reaction solution after passing chlorine is left to settle, and the settling time is 24h, and the supernatant is taken;

[0028] (4) Secondary sedimentation: the supernatant was left to settle for the second time, and the sedimentation time was 24 hours to obtain the second supernatant;

[0029] (5) Filtration:...

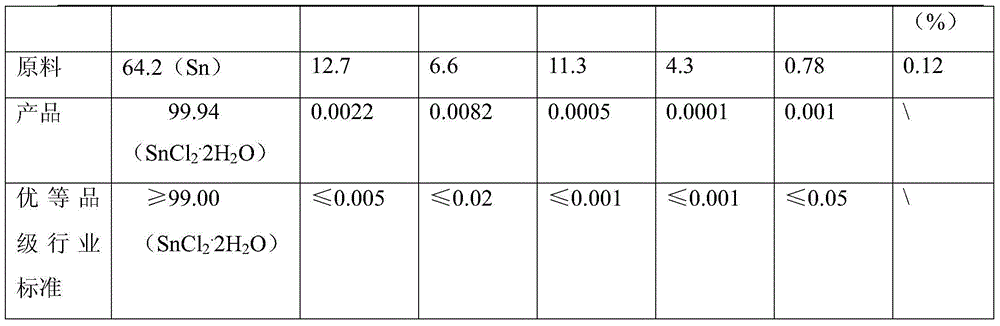

Embodiment 2

[0038] A kind of method utilizing low-tin waste slag to prepare excellent grade tin protochloride, comprises the following steps:

[0039] (1) Prepare reaction solution: take 200kg of low-tin waste residue and put it into 2m 3 Add 500L of water and mix uniformly, then add 300L of concentrated hydrochloric acid with a mass percentage of 37.5% to adjust the acidity to 3g / l; the low-tin waste slag is the waste slag produced in the process of producing tin processed products;

[0040] (2) Chlorine: feed chlorine gas into the reaction solution, and wait for the Sn in the reaction solution to 4+ Stop chlorine flow when the content reaches 450g / l;

[0041] (3) Settling: the reaction solution after passing chlorine is left to settle, and the settling time is 24h, and the supernatant is taken;

[0042] (4) Secondary sedimentation: the supernatant was left to settle for the second time, and the sedimentation time was 24 hours to obtain the second supernatant;

[0043] (5) Filtration:...

Embodiment 3

[0052] A kind of method utilizing low-tin waste slag to prepare excellent grade tin protochloride, comprises the following steps:

[0053] (1) Prepare reaction solution: take 200kg of low-tin waste residue and put it into 2m 3 Add 500L of water and mix uniformly, then add 300L of concentrated hydrochloric acid with a mass percentage of 37.5% to adjust the acidity to 3g / l; the low-tin waste slag is the waste slag produced in the process of producing tin processed products;

[0054] (2) Chlorine: feed chlorine gas into the reaction solution, and wait for the Sn in the reaction solution to 4+ Stop chlorine flow when the content reaches 450g / l;

[0055] (3) Settling: the reaction solution after passing chlorine is left to settle, and the settling time is 24h, and the supernatant is taken;

[0056] (4) Secondary sedimentation: the supernatant was left to settle for the second time, and the sedimentation time was 24 hours to obtain the second supernatant;

[0057] (5) Filtration:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com