Imitation-silver composite consumable with silver plating effect and for 3Dprinting and preparation method thereof

A technology of 3D printing and consumables, applied in the field of 3D printing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

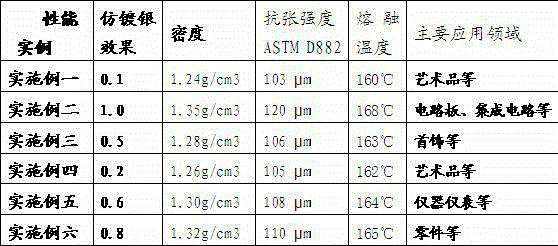

Examples

Embodiment 1

[0051] Using 1% metallic aluminum silver powder and 99% PLA (polylactide polylactic acid), the imitation silver composite consumables for 3D printing are produced through the following formula. Concrete preparation steps are as follows:

[0052] ①. Mix 1% metal aluminum silver powder and 99% PLA;

[0053] ② Put the prepared raw materials into a plastic dryer and dry at 80°C-100°C for 2-3 hours;

[0054] ③. Put the raw materials into the plastic extruder, heat them at a temperature of 180°C-210°C, plasticize and dissolve the raw materials in the screw barrel at high temperature, and extrude the raw materials at a screw speed of 30-60 RPM;

[0055] ④. The raw material extruded from the screw passes through the honeycomb extrusion die, and then enters the inner tapered stainless steel extrusion die to extrude the plastic line;

[0056] ⑤. The plastic line enters a 6-meter-long 10°C-15°C water tank with ice water to fully cool the forming wire;

[0057] ⑥. The wire enters the t...

Embodiment 2

[0061] Using 30% metal aluminum silver powder and 70% PLA, the imitation silver composite consumables for 3D printing are produced through the following formula. Concrete preparation steps are as follows:

[0062] ①. Mix 30% metal aluminum silver powder and 70% PLA;

[0063] ② Put the prepared raw materials into the dryer and dry them at a temperature of 90°C-100°C for more than 2 hours to reduce the moisture content of the raw materials to 0.2%-0.5%;

[0064]③. Put the dried raw materials into a plastic mixer and mix them thoroughly for 30 minutes;

[0065] ④. Put the mixed raw materials into the twin-screw granulator, heat at a temperature of 180°C-210°C, plasticize and dissolve the raw materials in the screw barrel at high temperature, and then extrude the raw materials at a screw speed of 30-60RPM;

[0066] ⑤. After the raw material extruded from the screw enters the granulation die, it is differentiated into thin strips, and is quickly cut into composite particles with ...

Embodiment 3

[0075] Using 10% metal aluminum silver powder and 90% PLA, the imitation silver composite consumables for 3D printing are produced through the following formula. Concrete preparation steps are as follows:

[0076] ①. Mix 10% metal aluminum silver powder and 90% PLA;

[0077] ② Put the prepared raw materials into the dryer and dry them at a temperature of 90°C-100°C for more than 2 hours to reduce the moisture content of the raw materials to 0.2%-0.5%;

[0078] ③. Put the dried raw materials into a plastic mixer and mix them thoroughly for 30 minutes;

[0079] ④. Put the mixed raw materials into the twin-screw granulator, heat at a temperature of 180°C-210°C, plasticize and dissolve the raw materials in the screw barrel at high temperature, and then extrude the raw materials at a screw speed of 30-60RPM;

[0080] ⑤. After the raw material extruded from the screw enters the granulation die, it is differentiated into thin strips, and is quickly cut into composite particles with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com