Polyamine shale inhibitor and preparation method thereof

A technology of shale inhibitor and polyamine, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improved compatibility, excellent inhibitory performance, and shortened reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

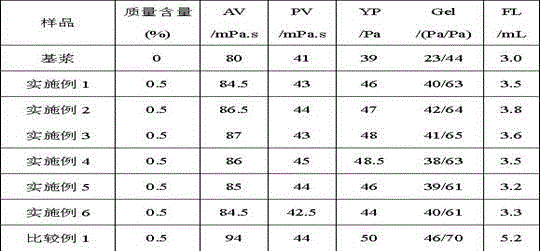

Embodiment 1

[0022] First set the reaction temperature to 65°C, stir and pass ethylene oxide into diethylenetriamine, the molar ratio of diethylenetriamine to ethylene oxide is 1:2, control the reaction temperature not lower than 60°C , react for 3h; then raise the temperature to 80°C, add epichlorohydrin dropwise under stirring condition, the molar ratio of epichlorohydrin to diethylenetriamine is 0.6:1, the reaction time is 2h, and finally add the terminator concentrated hydrochloric acid , the molar ratio of concentrated hydrochloric acid to diethylenetriamine is 1:1, and the polyamine shale inhibitor is prepared after 1 hour of reaction.

Embodiment 2

[0024] Set the reaction temperature to 75°C, stir and add propylene oxide dropwise into triethylenetetramine, the molar ratio of triethylenetetramine to propylene oxide is 1:3, control the reaction temperature not lower than 70°C, and react 2h; then raise the temperature to 90°C, add epichlorohydrin dropwise under stirring condition, the molar ratio of epichlorohydrin to diethylenetriamine is 0.5:1, and the reaction time is 3h; finally add the terminator formic acid, The molar ratio of formic acid to diethylenetriamine was 1.5:1, and the polyamine shale inhibitor was prepared after 1.5h of reaction.

Embodiment 3

[0026] Set the reaction temperature to 85°C, stir and add propylene oxide dropwise into tetraethylenepentamine, the molar ratio of tetraethylenepentamine to propylene oxide is 1:2.5, control the reaction temperature not lower than 80°C, and react 1.5h; then raise the temperature to 100°C, add epichlorohydrin dropwise under stirring, the molar ratio of epichlorohydrin to diethylenetriamine is 0.8:1, and the reaction time is 2h; finally add the terminator acetic acid , the molar ratio of acetic acid to diethylenetriamine was 1.8:1, and the polyamine shale inhibitor was prepared after 1 hour of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com