Electrochemical additive manufacturing method with measuring feedback, and apparatus thereof

A technology of electrochemical machining and chemical reaction, applied in electrochemical manufacturing, electrochemical method for additive manufacturing, namely three-dimensional printing field, can solve the problem of difficult to control dimensional accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

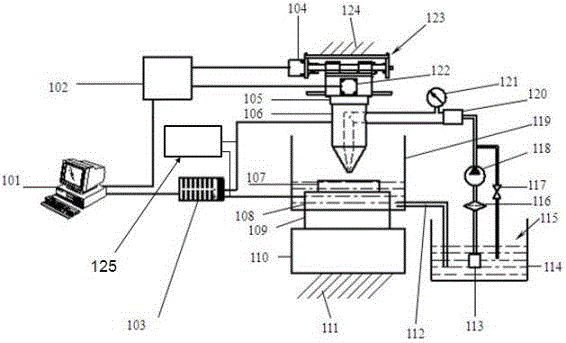

Image

Examples

Embodiment 1

[0012] The electrochemical method is used for subtractive manufacturing, and 80% saturated sodium chloride solution is used as the working medium. The material of the working electrode is an insoluble titanium electrode coated with iridium dioxide on the surface, and the working electrode is a slender cylinder with a diameter of 3 mm. The workpiece is tungsten steel, because of its high hardness, it is not suitable for surface engraving and milling by traditional machining methods. Connect the workpiece to the positive pole of the controller, and the working electrode to the negative pole of the controller. The workpiece and the working electrode are immersed in the working medium at the same time, and the working medium is installed in the working container and circulated through the pump to dissipate heat in the working container and the radiator to avoid overheating. A baseline operating current density of 10,000 amperes per square meter was used. Superimpose the AC curre...

Embodiment 2

[0014] The electrochemical method is used for additive manufacturing, and the bright nickel electroplating solution is used as the working solution. The material of the working electrode is an insoluble titanium electrode coated with iridium dioxide on the surface, and the working electrode is a slender cylinder with a diameter of 3 mm. The base material of the workpiece is a nickel plate. Connect the workpiece substrate to the negative pole of the controller, and the working electrode to the positive pole of the controller. The workpiece substrate and the working electrode are immersed in the working fluid at the same time, and the working fluid is contained in the working container and circulated through the pump to dissipate heat in the working container and the radiator to avoid overheating. A baseline operating current density of 1000 amperes per square meter was used. Superimpose the AC current with a frequency of 3000 Hz and an amplitude of 1 / 100 of the working curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com