A kind of preparation method of surface micro-hydrogenated titanium or titanium alloy powder

A technology of titanium alloy and powder, which is applied in the field of preparation of titanium or titanium alloy powder, can solve the problem of uncontrollable hydrogen absorption process of double-layer atomization nozzle, achieve good fluidity and oxidation resistance, less pollution, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of the titanium or titanium alloy powder of surface slight hydrogenation, carry out according to the following steps:

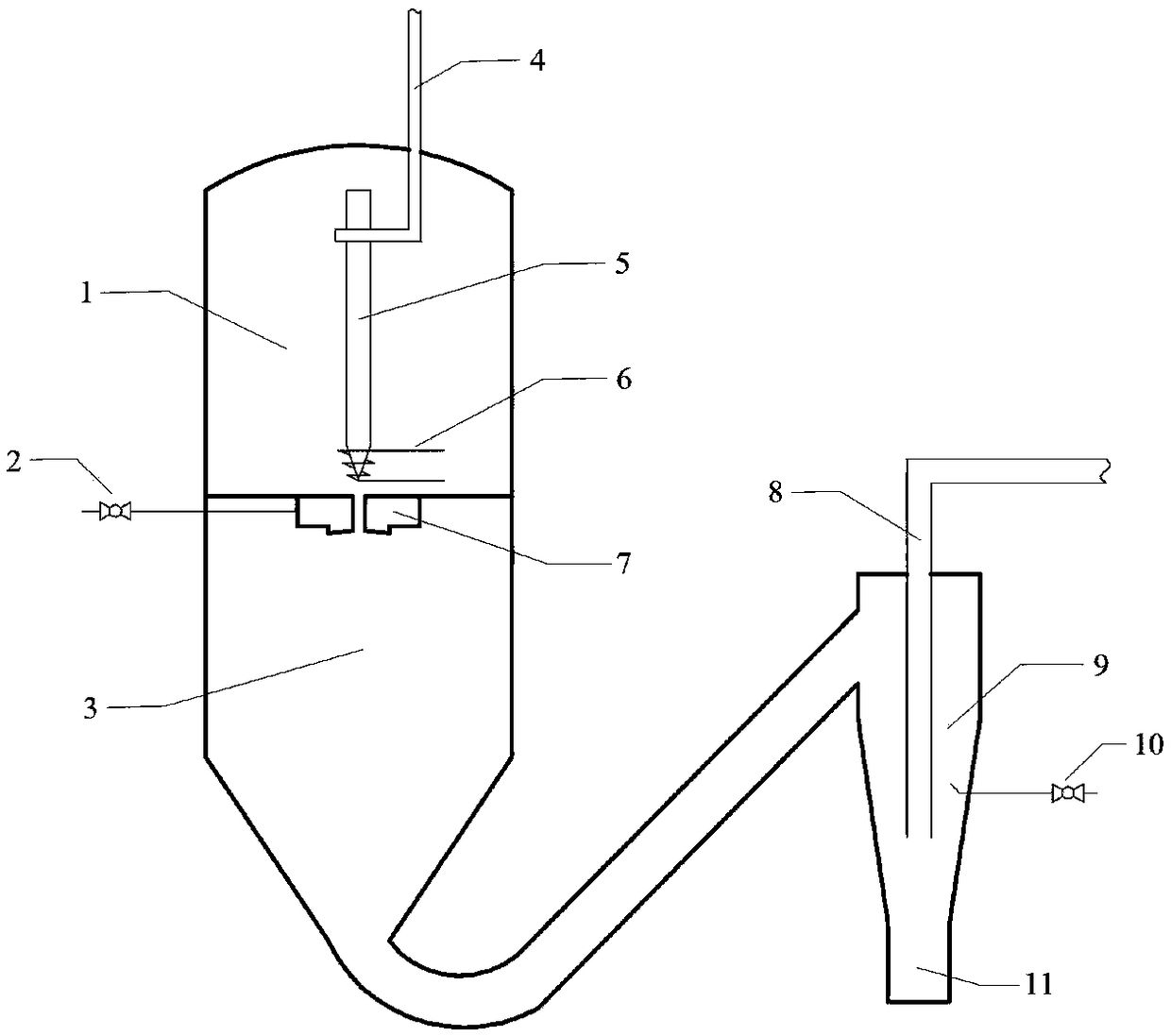

[0018] (1) According to milling needs and equipment requirements, such as figure 1 , pre-preparing titanium or titanium alloy rods with low pollution and specific dimensions 5;

[0019] (2) Pre-evacuate the interior of the melting chamber 1, atomization chamber 3 and cyclone separator 9 in the atomization device until the vacuum degree reaches 1×10 -4 ~1×10 -2 Pa, filled with 0.09 MPa high-purity inert gas protection through the atomizing gas valve 2 to prevent the oxidation of the powder during the atomization process;

[0020] (3) The lower end of the titanium or titanium alloy rod 5 is heated and melted by the induction coil 6, and a stable liquid flow is formed by controlling the feeding rod 4, and then atomized and powdered by the atomizing nozzle 7 using high-purity inert gas as the medium , the atomization pressu...

Embodiment 1

[0025] Surface slightly hydrogenated Ti-6Al-4V (TC4) alloy powder prepared by crucible-free gas atomization method.

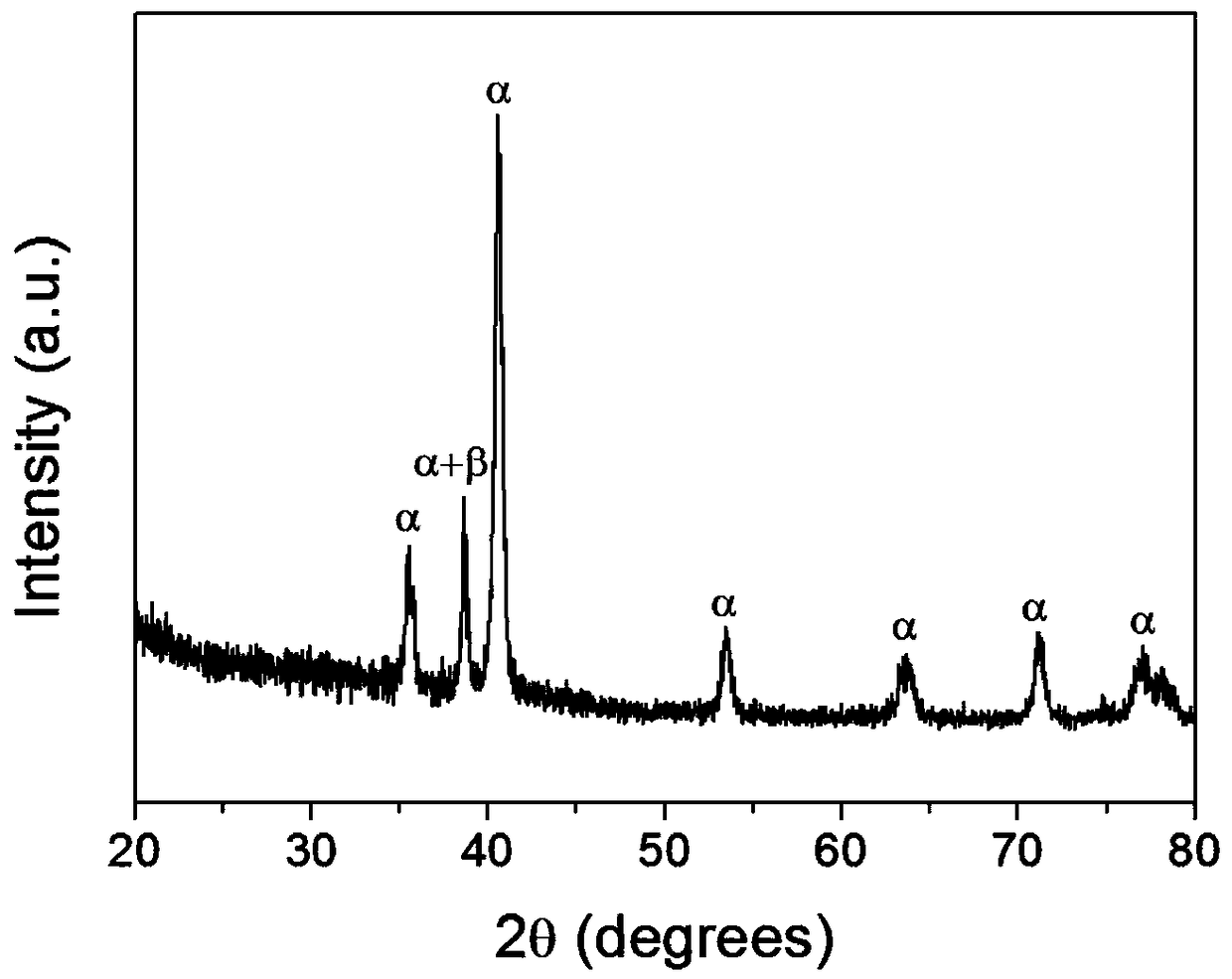

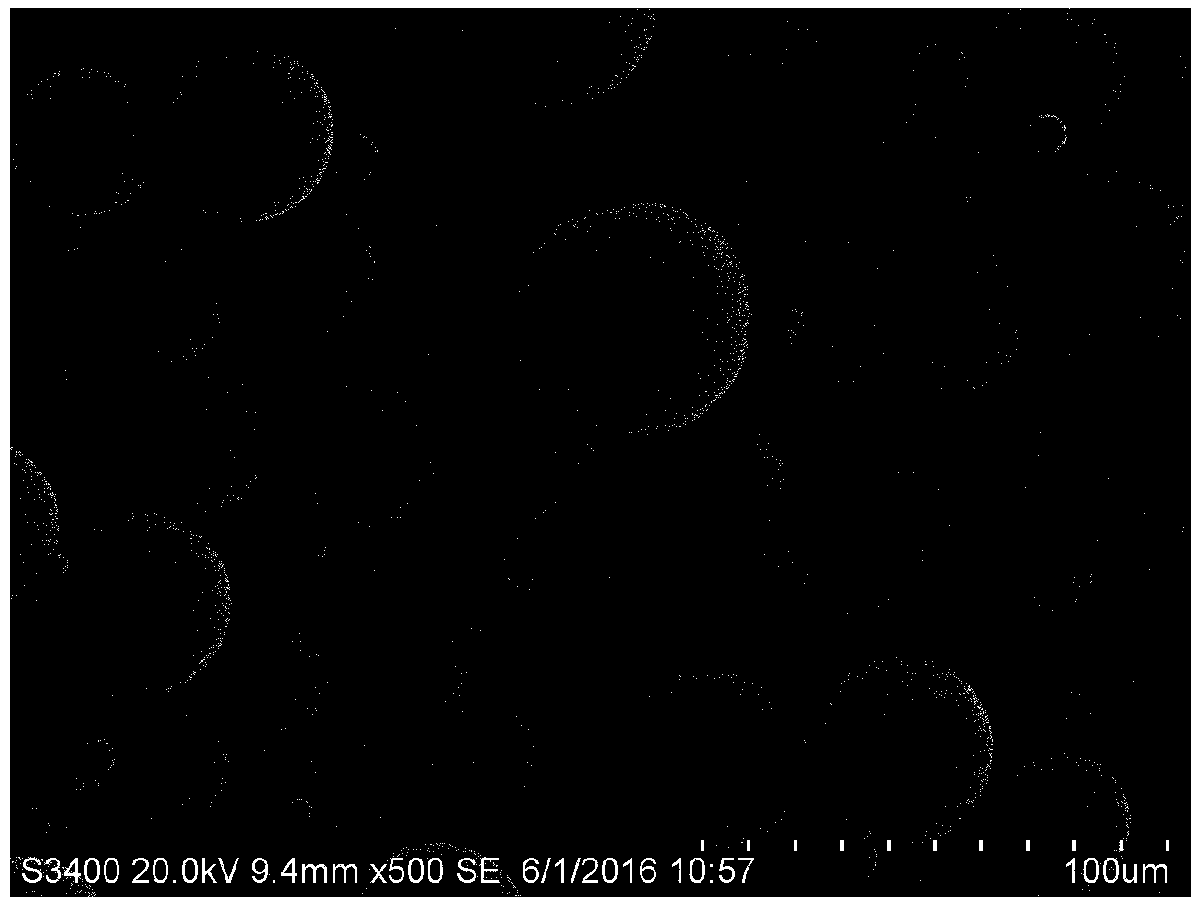

[0026] Using TC4 titanium alloy rods with a diameter of 40mm and an impurity content of less than 0.1% as raw materials, pre-evacuate the atomization equipment until the vacuum degree reaches 1×10 -4 Pa, filled with 0.09 MPa high-purity argon protection to prevent oxidation. The lower end of the titanium alloy rod is heated and melted by the induction coil to form a stable liquid flow, and then atomized and powdered through the atomizing nozzle with high-purity argon as the medium, the atomizing pressure is controlled at 5-7 MPa, and the atomization is completed The titanium alloy powder is carried into the cyclone separator by the air flow, and the lower part of the cyclone separator is fed with a mixed gas of hydrogen and argon with a hydrogen content of 10 at.% at 0.3 MPa. The position of the air inlet should be higher than the exhaust port in the cyclone se...

Embodiment 2

[0028] Surface slightly hydrogenated Ti-45Al-2Cr-8Nb alloy powder prepared by crucible-free gas atomization method.

[0029] Using Ti-45Al-2Cr-8Nb titanium alloy rods with a diameter of 40mm and an impurity content of less than 0.1% as raw materials, pre-evacuate the atomization equipment until the vacuum degree reaches 1×10 -4 Pa, filled with 0.09 MPa high-purity helium protection to prevent oxidation. The lower end of the titanium alloy rod is heated and melted by the induction coil to form a stable liquid flow, and then atomized and powdered through the atomizing nozzle with high-purity helium as the medium, the atomizing pressure is controlled at 6~8 MPa, and the atomization is completed The titanium alloy powder is carried into the cyclone separator by the air flow, and the lower part of the cyclone separator is fed with a mixed gas of hydrogen and helium with a hydrogen content of 25 at.% at 0.5 MPa. The position of the air inlet should be higher than the exhaust port in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com