Preparation method of high-resilience low-draft differential melt-spun polyurethane filament

A high-resilience, spandex yarn technology, applied in melt spinning, rayon manufacturing, filament/thread forming, etc., can solve the problems of skinning pipes that are easy to adhere to the pipe wall, strength, resilience and temperature resistance , Difficult to clean and other problems, to achieve the effect of easy unwinding, high elastic recovery rate, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

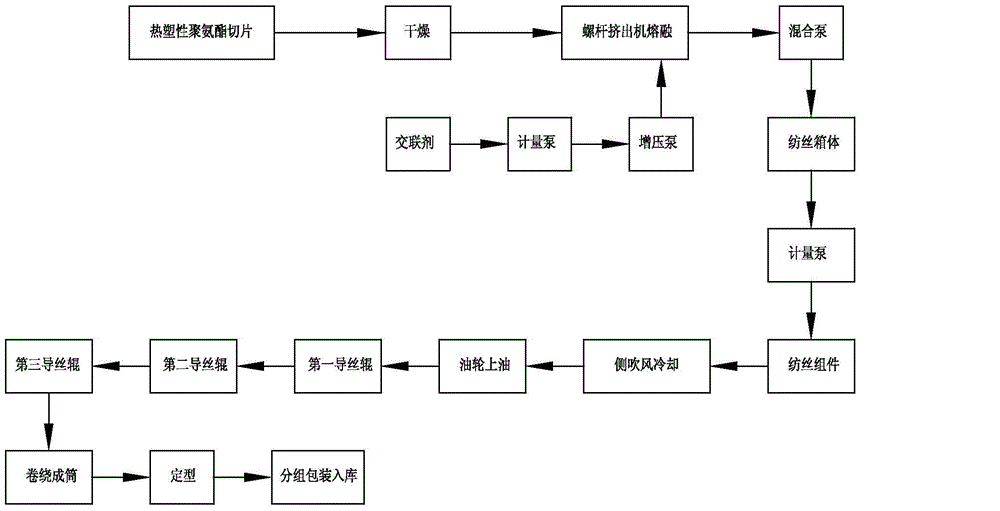

Image

Examples

Embodiment 1

[0021] The present invention is a method for preparing differentiated melt-spun spandex yarns with high resilience and low draft, and the specific steps are as follows:

[0022] 1. Cut an appropriate amount of thermoplastic polyurethane into slices and dry them at 85°C for 5 hours;

[0023] 2. Put the dried chips into the screw extruder for melting;

[0024] 3. Input the cross-linking agent with a proportion of 13% into the metering pump for metering, and then add it into the screw extruder through the booster pump;

[0025] 4. After the chips and the crosslinking agent are heated and melted through the fourth zone of the screw extruder at 100-220°C, they are added to the mixing pump to be mixed into a molten mixture;

[0026] 5. After the molten mixture in the mixing pump is pressed into the melt pipe in the spinning box, it is then distributed to the spinning metering pumps at different spinning positions and sent to the spinning assembly, and extruded to obtain a fine melt...

Embodiment 2

[0032] The present invention is a method for preparing differentiated melt-spun spandex yarns with high resilience and low draft, and the specific steps are as follows:

[0033] 1. Slice an appropriate amount of thermoplastic polyurethane and dry it at 87°C for 5.5 hours;

[0034] 2. Put the dried chips into the screw extruder for melting;

[0035] 3. Input the cross-linking agent with a ratio of 15% into the metering pump for metering, and then add it into the screw extruder through the booster pump;

[0036] 4. After the chips and the crosslinking agent are heated and melted through the fourth zone of the screw extruder at 100-220°C, they are added to the mixing pump to be mixed into a molten mixture;

[0037] 5. After the molten mixture in the mixing pump is pressed into the melt pipe in the spinning box, it is then distributed to the spinning metering pumps at different spinning positions and sent to the spinning assembly, and extruded to obtain a fine melt. flow;

[00...

Embodiment 3

[0043] The present invention is a method for preparing differentiated melt-spun spandex yarns with high resilience and low draft, and the specific steps are as follows:

[0044] 1. Slice an appropriate amount of thermoplastic polyurethane and dry it at 88°C for 5.8 hours;

[0045] 2. Put the dried chips into the screw extruder for melting;

[0046] 3. Input the cross-linking agent with a ratio of 16% into the metering pump for metering, and then add it into the screw extruder through the booster pump;

[0047] 4. After the chips and the crosslinking agent are heated and melted through the fourth zone of the screw extruder at 100-220°C, they are added to the mixing pump to be mixed into a molten mixture;

[0048] 5. After the molten mixture in the mixing pump is pressed into the melt pipe in the spinning box, it is then distributed to the spinning metering pumps at different spinning positions and sent to the spinning assembly, and extruded to obtain a fine melt. flow;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com